Integrated high-pressure anti-blocking sucking, flushing and digging dredging equipment

A high-pressure, anti-blocking technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problem of restricting the progress and development of dredging engineering technology, unable to meet actual needs, and low dredging efficiency and other problems, to achieve the effect of reducing the dredging intensity, simple and compact structure, and enhancing the dredging function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

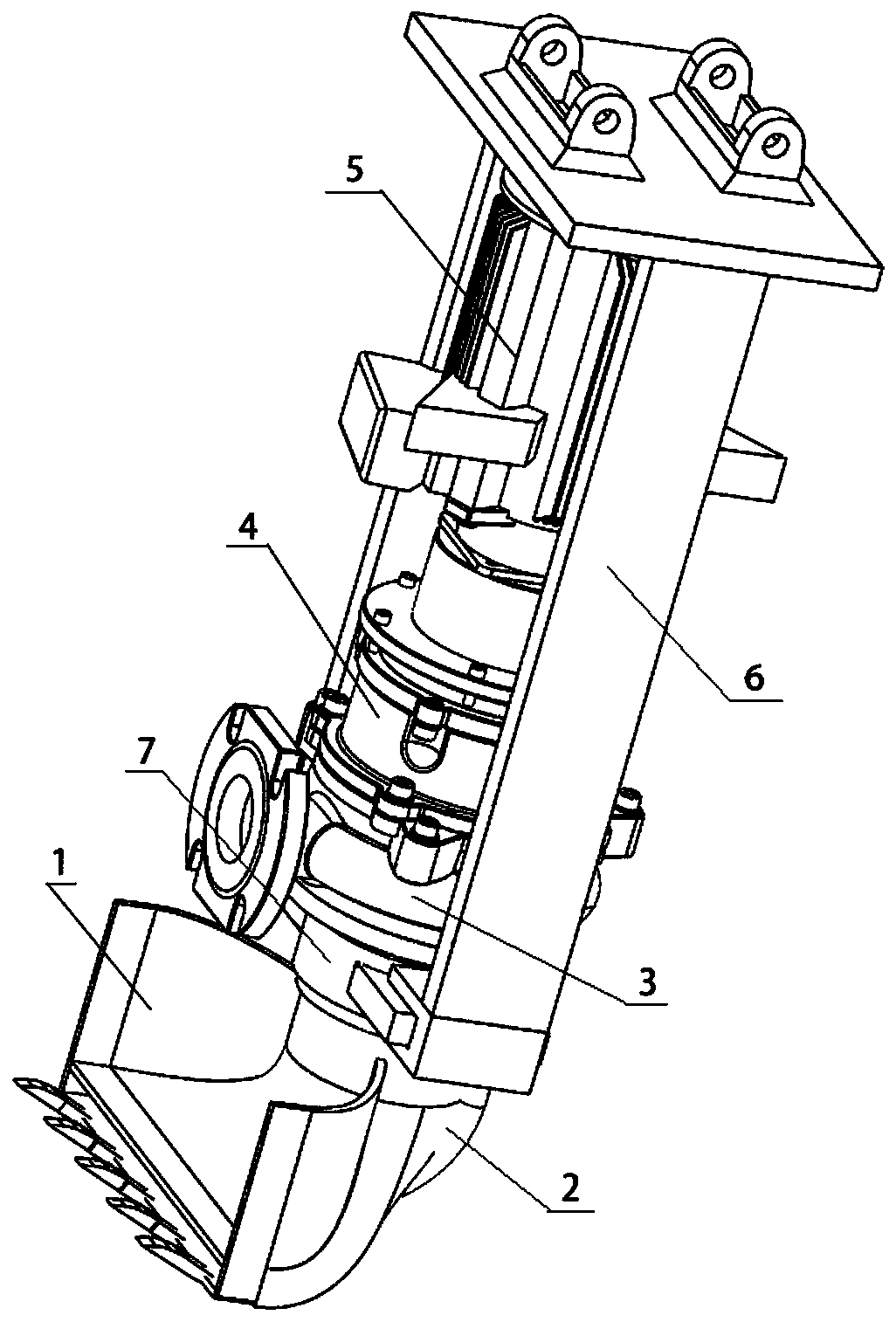

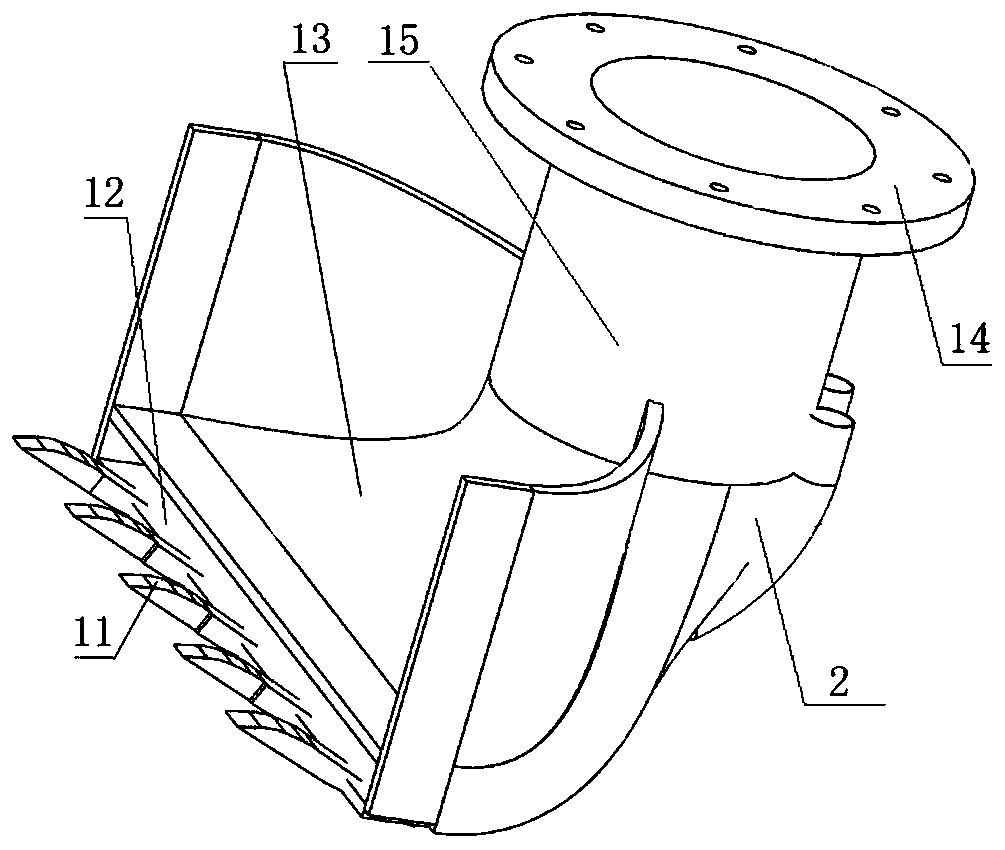

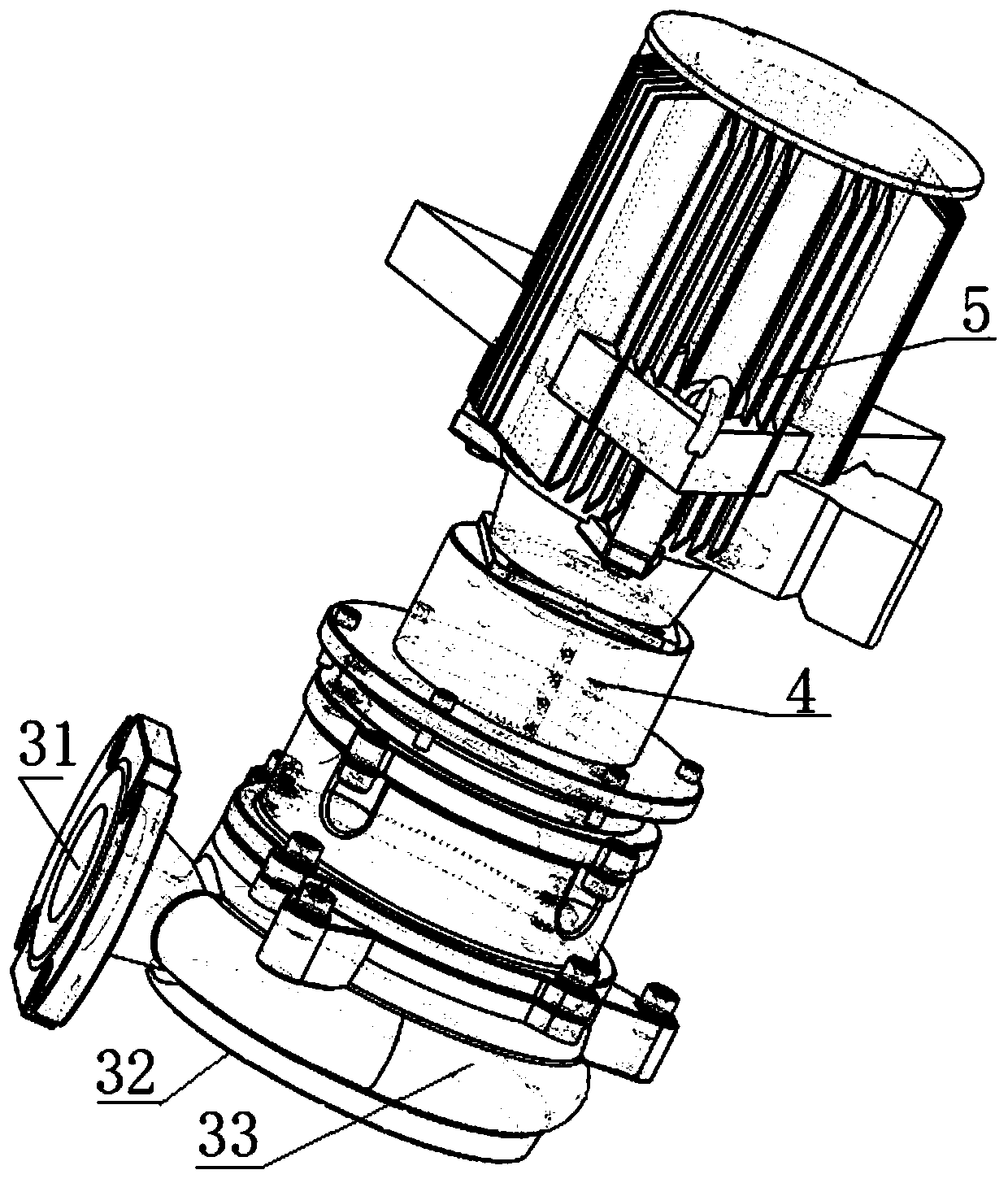

[0040] Example: as attached figure 1 , 2 , 3, 4, and 5, the top of the manipulator 1 is fixedly connected to the cutting pump 3 through the flange 14; the bottom of the manipulator 1 and the interior of the rear wall are cavity streamlined flow channels and communicate with the upper cutting pump 3, which can effectively reduce hydraulic loss The anti-clogging injection device 2 is welded on the back of the manipulator 1, and the bottom of the anti-silting injection device 2 communicates with the interior of the manipulator 1; the upper end of the cutting pump 3 is connected with the hydraulic motor 5 through the coupling 4, and the cutting pump 3, the coupling 4 and the The main equipment of the hydraulic motor 5 is fixedly connected with the mechanical connecting frame 6 by bolts through a hoop 7 .

[0041] In the foregoing, the manipulator 1 includes rake teeth 11 , a flat mud inlet 12 , a bucket 13 , a flange 14 and a connecting pipe 15 . The manipulator 1 uses a shovel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com