Building shading cast-in-place concrete lattice wall and construction method thereof

A construction method and concrete technology, which can be applied to buildings, building components, building structures, etc., can solve the problems of safety risks, can not withstand the sun and rain, and the sunshade facilities are not strong enough, so as to reduce the project cost, shorten the construction period, Good shading and ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

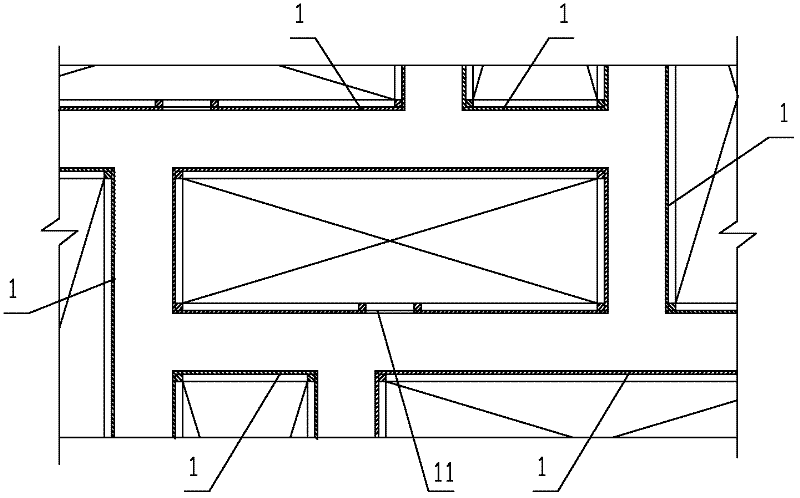

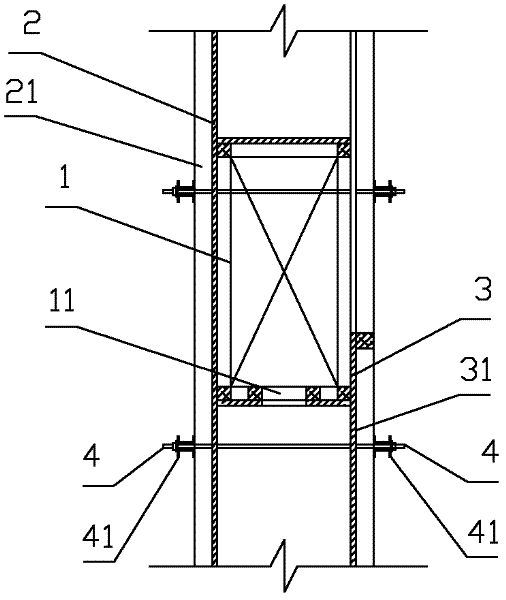

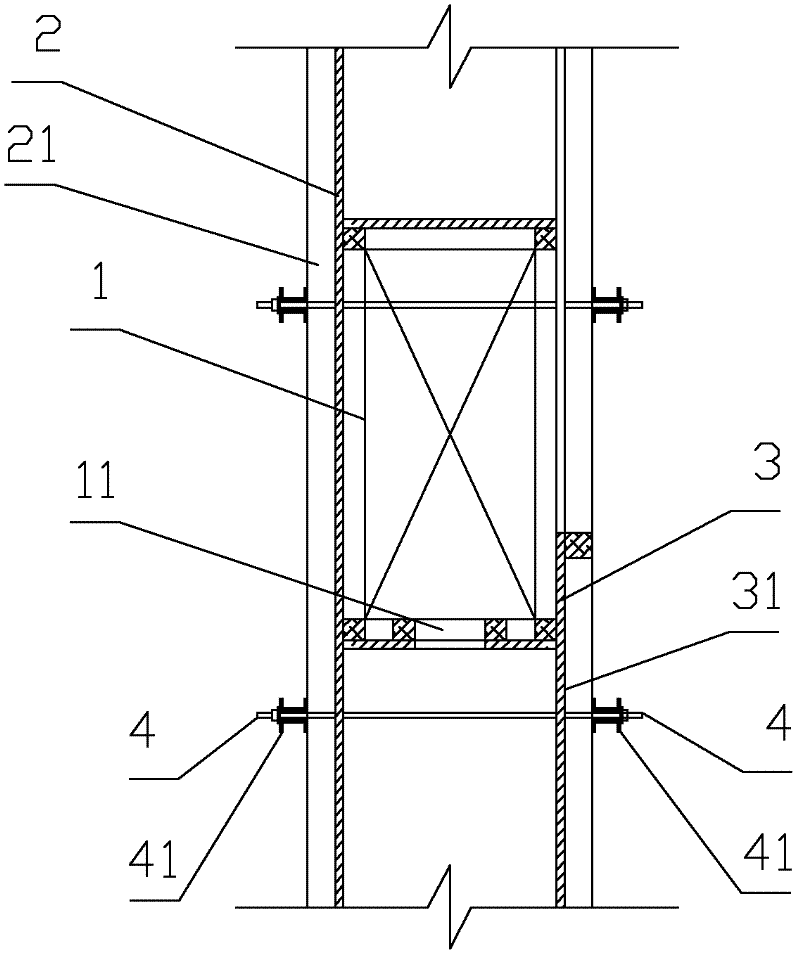

[0024] Combine below figure 1 and figure 2 Specifically explain a kind of building sunshade cast-in-place concrete lattice wall and construction method,

[0025] Firstly, the structure of the cast-in-place concrete lattice wall for building sunshade is described, including the concrete poured lattice wall body, and the steel bars are pre-embedded in the wall body during pouring. The steel bar is provided with a protective layer of plastic pads, and the plastic pads are embedded in concrete during pouring, and the color of the plastic pads is consistent with the color of the concrete.

[0026] Next, explain the formwork structure. The formwork includes the outer formwork 2, the inner formwork 3 and several mandrels 1 clamped and fixed between the outer formwork and the inner formwork. The mandrel includes keels and diagonal braces in the keels. Structure; wherein the inner formwork is installed and fixed in layers according to the layered concrete pouring of the lattice wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com