Hydraulic lifting self-ascending template system of intelligent independent unit structure

A technology of independent unit and lifting system, which is applied to the scaffolding of building structure support, building structure support, building structure support, etc., which can solve the problems of reducing safety risks at support points, and achieve the effect of saving man-hours and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

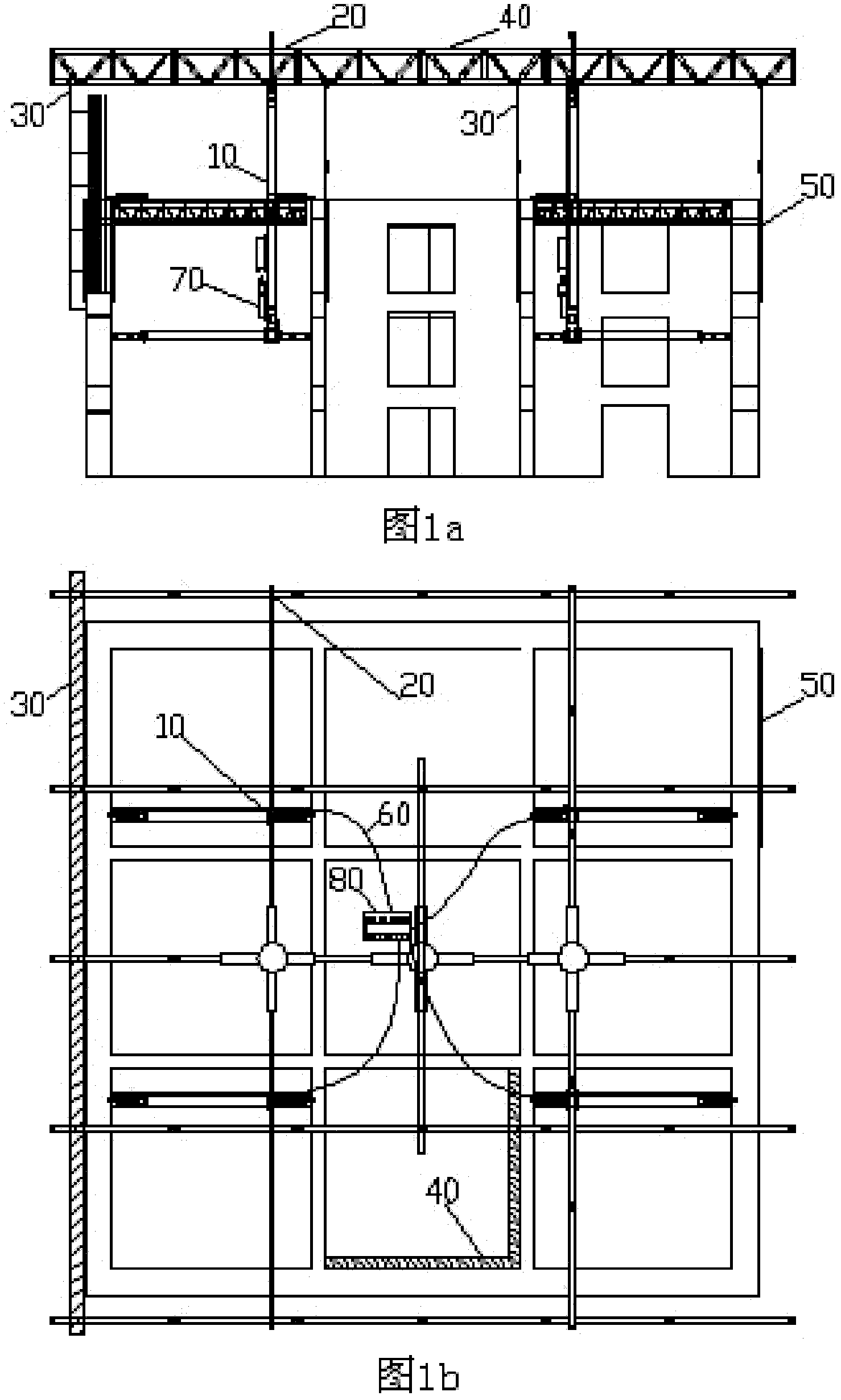

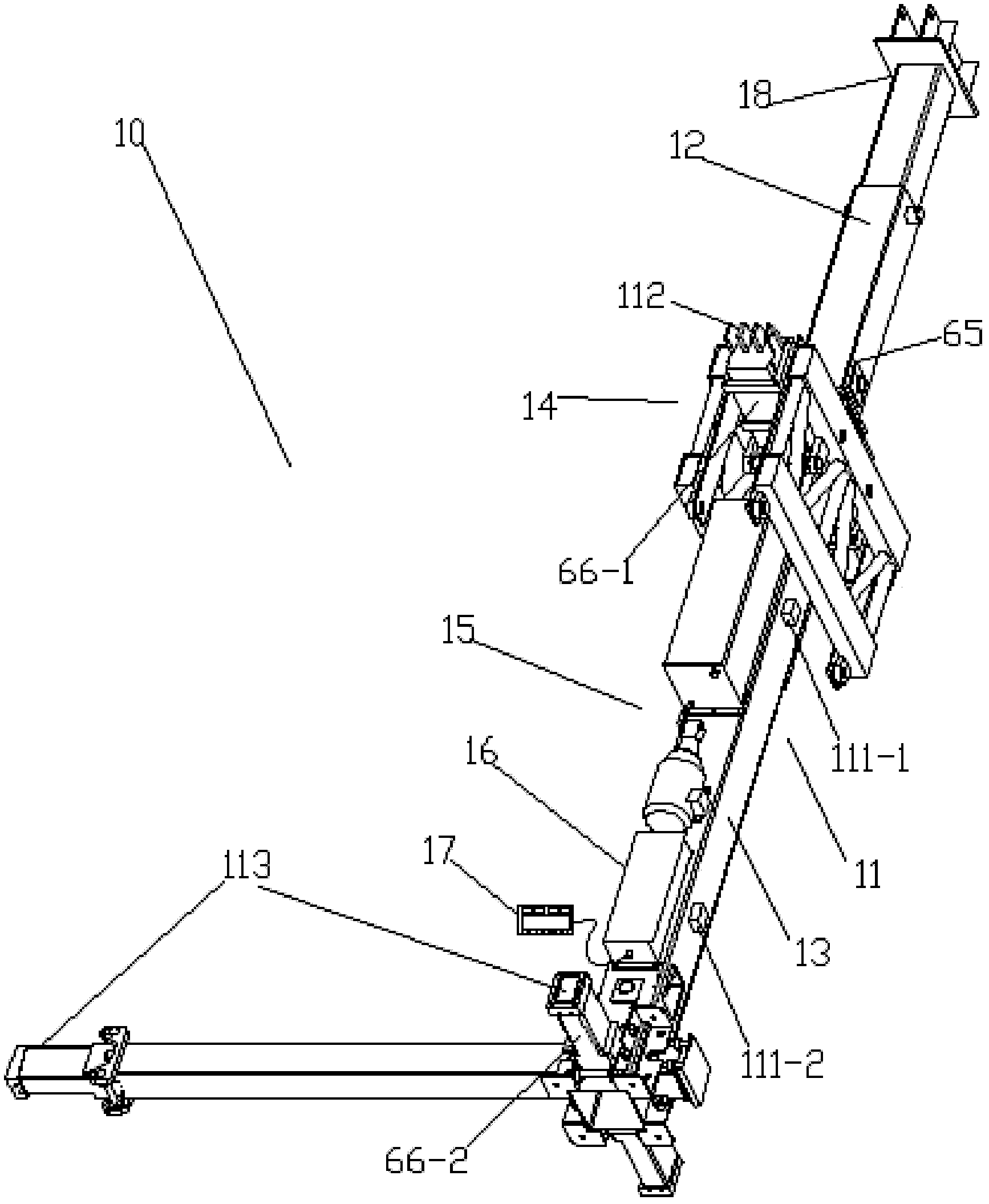

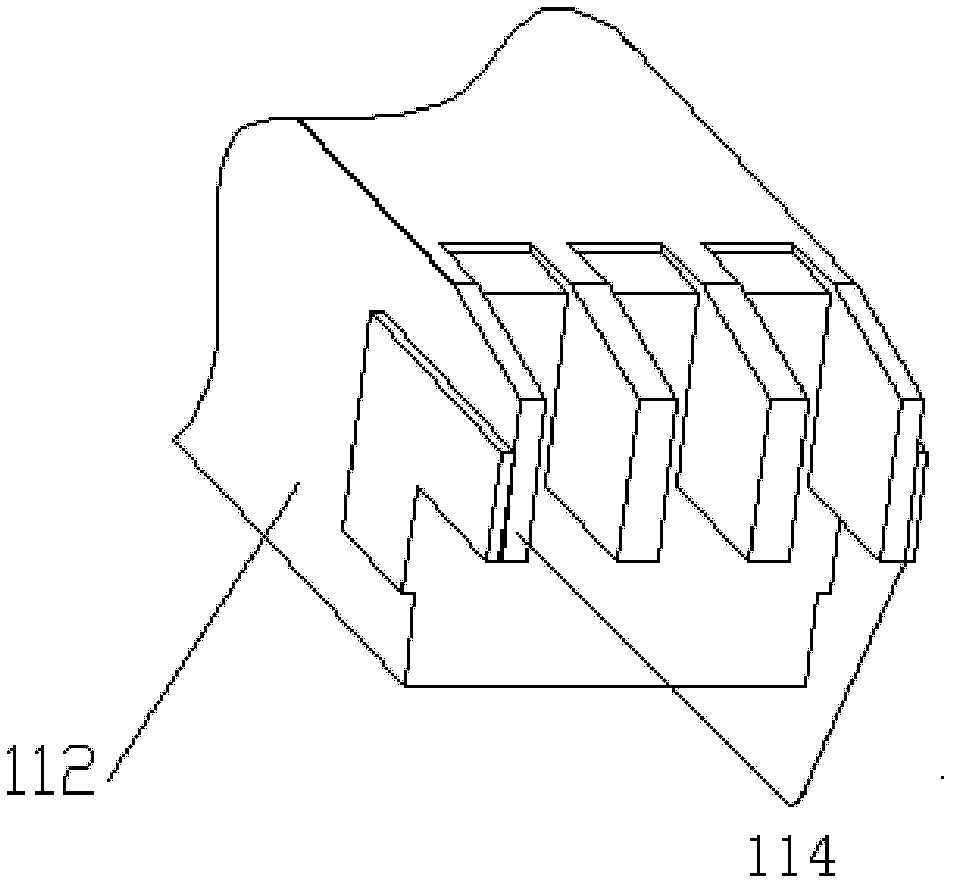

[0032] Such as figure 1 As shown, the hydraulic jacking self-climbing formwork system of an intelligent independent unit structure of the present invention includes a support system 10, a steel truss system 20 placed on the support system 10, and hung on the steel truss system 20 The operating platform system 40 and the formwork system 50 on the platform, as well as the hoisting system 60, the total electrical control system 70 and the touch screen general control panel 80 that drive the operation platform system 40 and the formwork system 50 to realize jacking and adjust their balance. , the touch screen general control panel 80 is used to control the lifting method, which can lift all the templates at one time at the same time, the programmable pouring height and the position display of each main column can realize precise movement and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com