Gob-side entry retaining method using prefabricated walls

A technology of prefabricated walls and retaining roadways, which is applied in mining equipment, earthwork drilling, shaft lining, etc. It can solve the problems of air leakage from wooden piles and dense pillars, slow project progress, and large shrinkability, etc., and achieve simple construction technology , the effect of small roadway deformation and short impact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

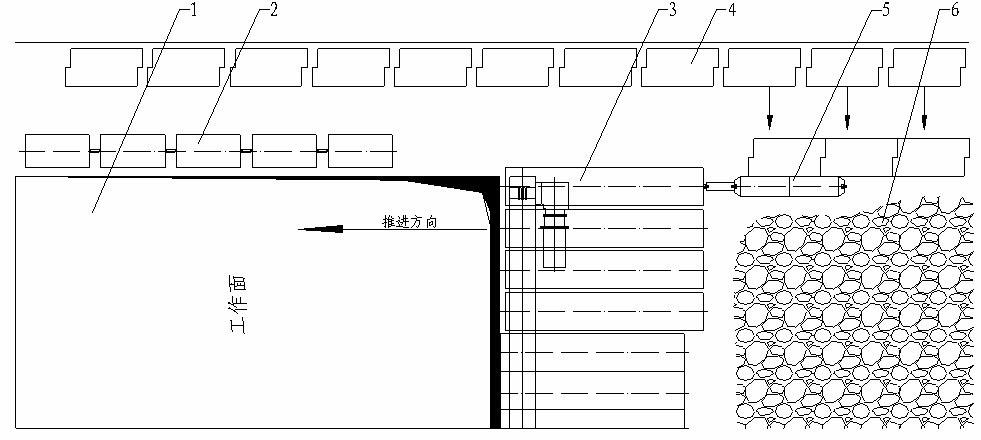

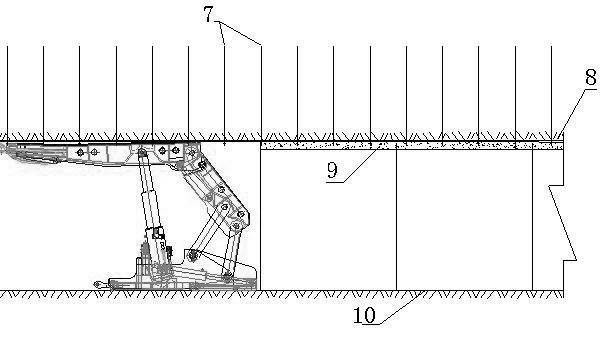

[0014] In order to clearly illustrate the technical characteristics of the solution, the following describes the solution through a specific implementation mode in conjunction with the accompanying drawings.

[0015] Examples, such as figure 1 In the roadway structure shown, the above-mentioned method for retaining a roadway along the gob using prefabricated walls includes the steps: a. Fixing the prefabricated wall template on the side of the roadway mining face 1 where the mobile substation 2 is set; b. Performance Self-compacting concrete is injected into the pre-fixed formwork on the side of the roadway in advance, and after solidification, a concrete wall block 4 with strong bearing capacity is formed; c In the goaf 6 in the roadway, hydraulic supports 3 are used first when mining Then drag the prefabricated concrete wall block 4 to the support frame position beside the lane; d adjust the wall block 4 to form a supporting wall; e use sealing material to pour the gap between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com