Safe drum brake

A drum brake and safety technology, applied in the direction of mechanically driven drum brakes, brake actuators, etc., can solve the problems of large vehicle braking sliding distance and poor drum brake braking effect, so as to improve braking reliability and improve braking performance. Effect of stability, good braking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

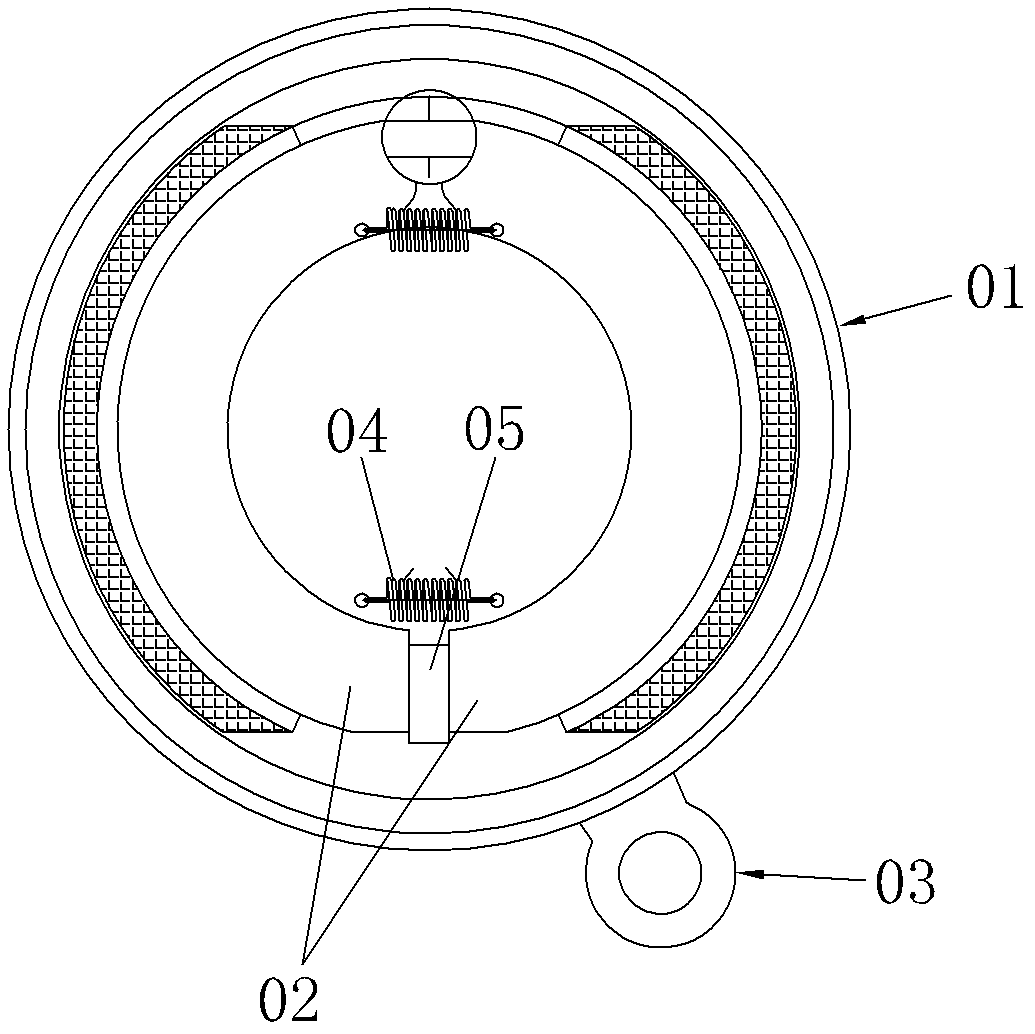

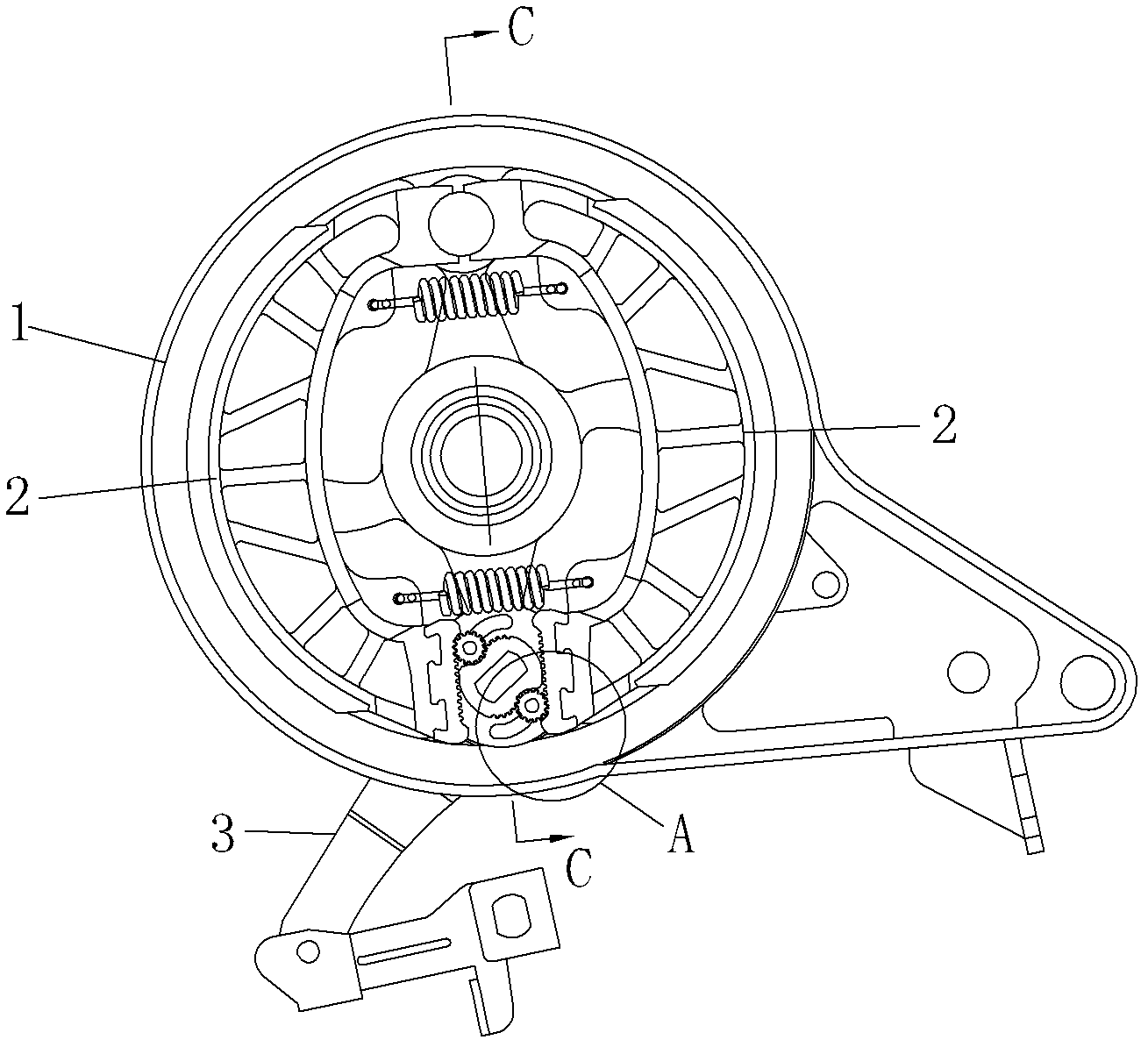

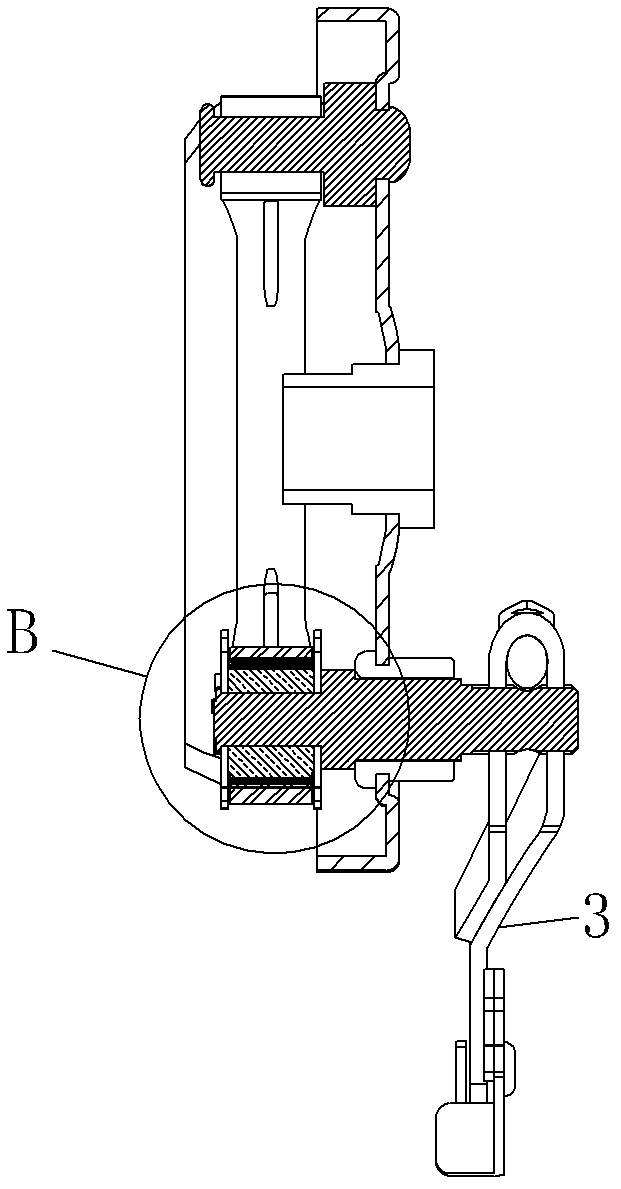

[0021] refer to Figure 2-4 , a safety drum brake, comprising a casing 1, a pair of brake shoes 2 and a brake arm assembly 3, one end of the brake shoe 2 is connected to the casing, and a gap between the other end of the brake shoe 2 and the brake arm The brake wheel 4 connected to the component 3, the roller 5 abuts between the brake wheel 4 and the brake shoe 2, also includes a positioning structure for the roller 5, the positioning structure includes a positioning plate 6, and the positioning plate 6 is provided with a limiting groove 61 , the roller 5 is provided with a protrusion embedded in the limiting groove 61. When the brake wheel 4 pushes the roller 5, the roller 5 always moves within the trajectory set by the limiting groove 61. The principle can refer to the applicant The previously applied patent number "2011203340168" and the invention patent named "a new type of drum brake" will not be described in detail here.

[0022] On the basis of the existing drum brake,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com