Round-table-type dense rib hot-blast furnace

A hot blast stove and table-top technology, which is applied in the field of round table-type dense-reinforced hot blast stove, can solve problems such as low temperature of molten iron, waste of energy, hanging materials, etc., and achieve high casting yield, reduce production costs, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

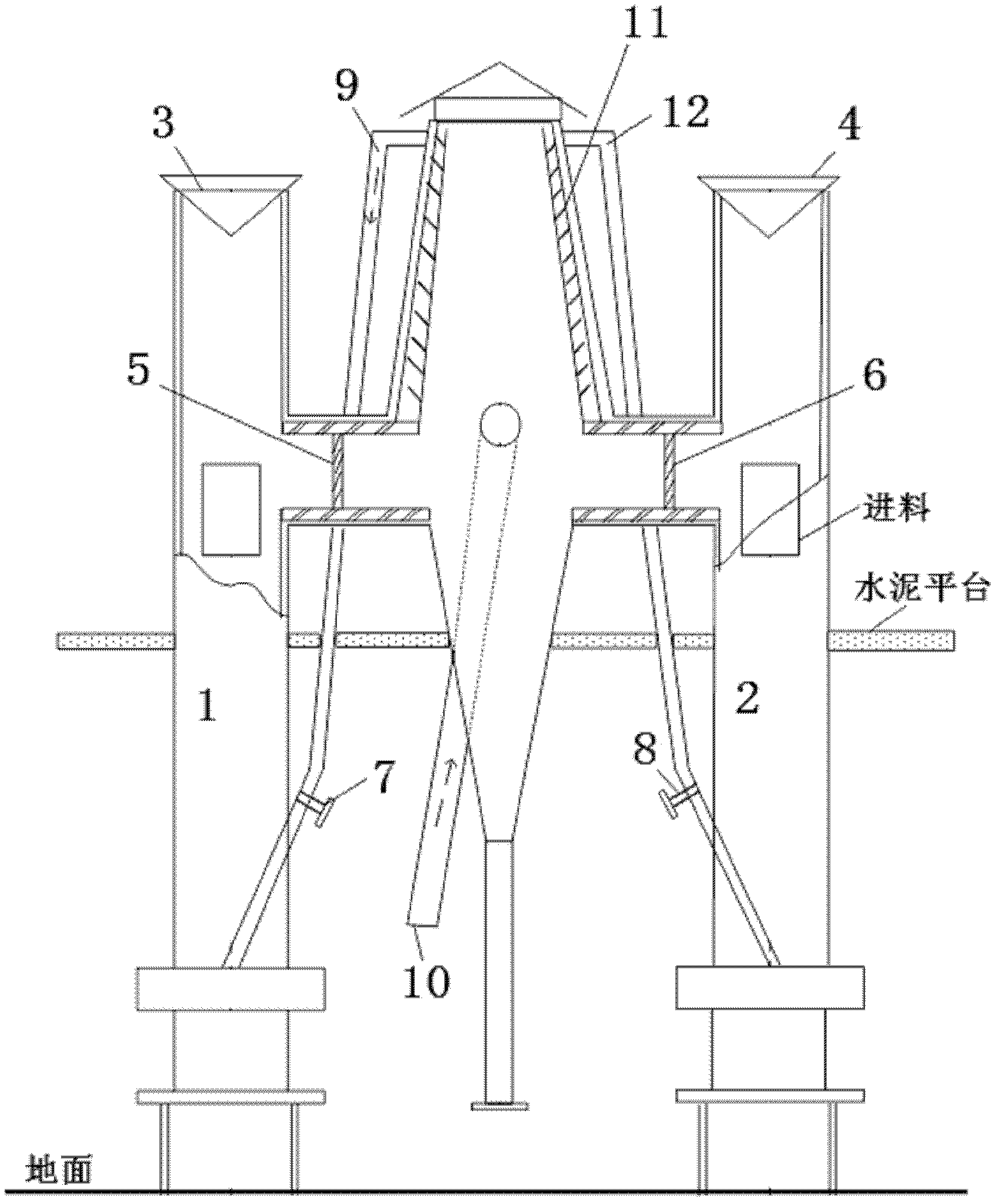

[0013] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Referring to the accompanying drawings, a round table-type dense rib hot blast stove includes a furnace body 11 composed of two upper and lower round tables. The gate 5 and the right feed gate 6, the left feed gate 5 communicates with the left cupola 1, the right feed gate 6 communicates with the right cupola 2, and the upper part of the furnace body 11 is provided with a left air duct 9 and a right air duct 12. The other end of the left air duct 9 is provided with a left valve 7 and communicates with the left cupola 1, and the other end of the right air duct 12 is provided with a right valve 8 communicated with the right cupola 2, and the top of the left cupola 1 is set There is a left furnace cover 3, and a right furnace cover 4 is arranged on the top of the right cupola 2.

[0015] Working principle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com