Compressed air profiling blowing device

A technology of compressed gas and compressed gas, which is applied in the directions of drying gas layout, drying, and dryer, etc., can solve the problems of large construction investment and energy consumption, adverse impact on the production environment, unsatisfactory drying effect, etc. Drying effect, eliminate noise pollution, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

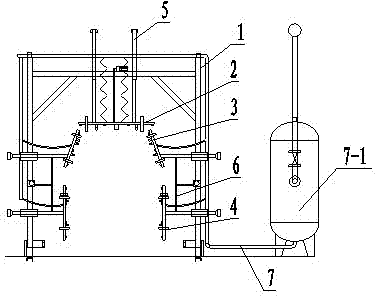

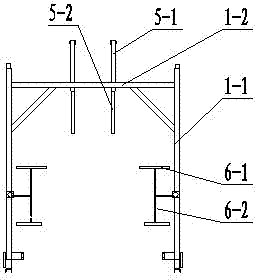

[0019] Referring to Fig. 1, the composition of the present invention includes a gantry frame 1, a top profiling blow-drying mechanism 2, a side profiling blow-drying mechanism, a top guide mechanism 5, a side guide mechanism 6 and a compressed air circuit 7, the top profiling Drying mechanism 2 is installed on top guide mechanism 5 lower ends, and described top guide mechanism 5 is fixed on the gantry top beam 1-2, and described side profiling blow-dry mechanism and side guide mechanism all comprise two left and right symmetrical arrangements. They are fixed inside the columns on both sides of the gantry frame, and the side profiling drying mechanism on the same side is fixedly connected with the side guide mechanism 6. The compressed air circuit 7 is arranged along the outside of the gantry frame, and its end is connected to the air storage tank. 7-1.

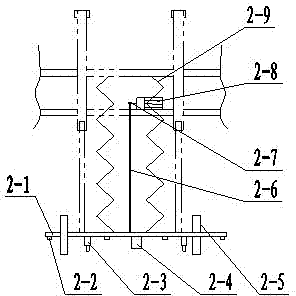

[0020] see figure 1 , image 3 , the top profiling drying mechanism in the composition of the present invention comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com