Rail straining and sensing method based on bidirectional strain matching fiber grating demodulating technique

A fiber grating demodulation and fiber grating technology, which is applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of influence and the influence cannot be well eliminated, and achieve the effect of high sensitivity, simple structure and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

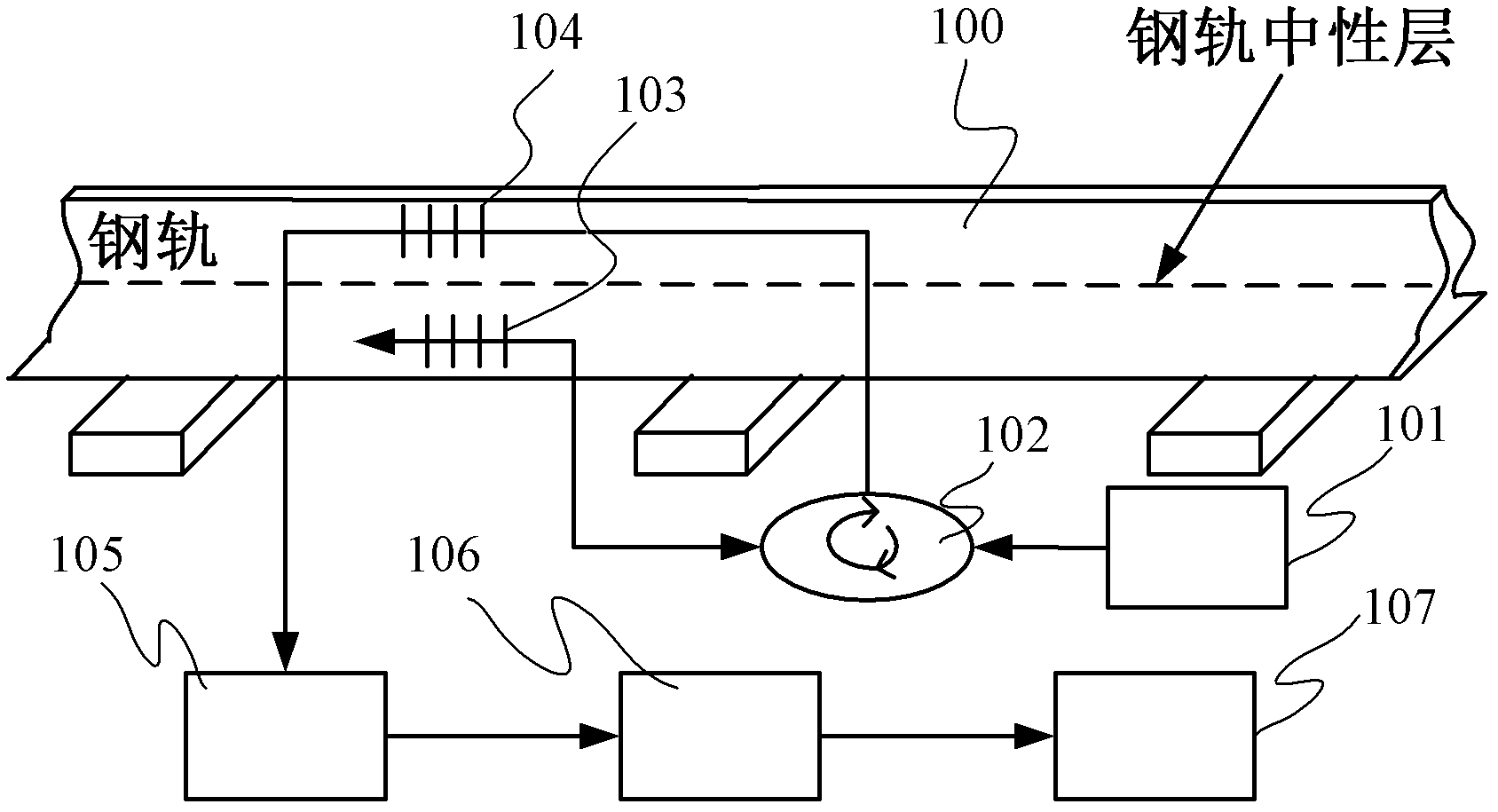

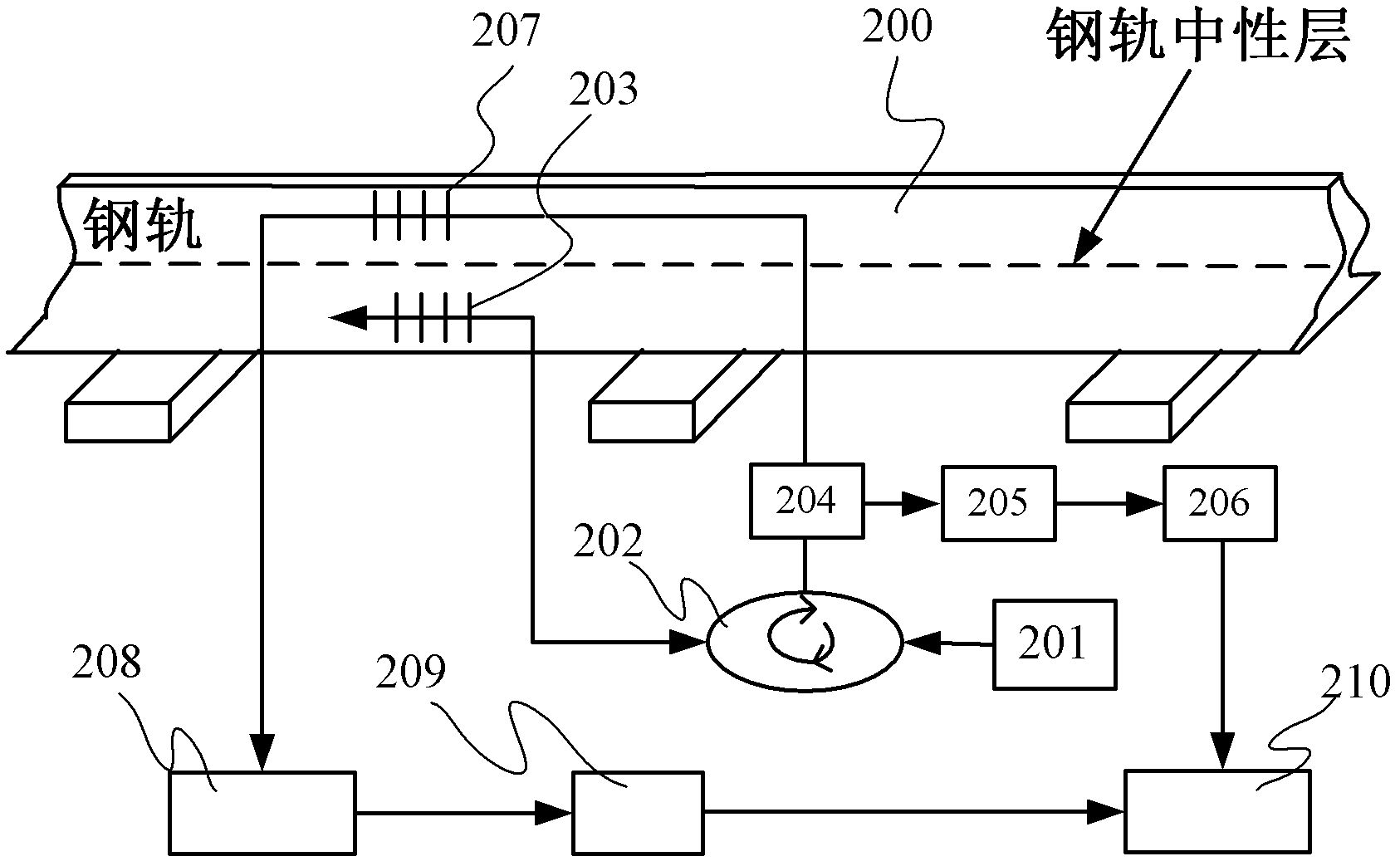

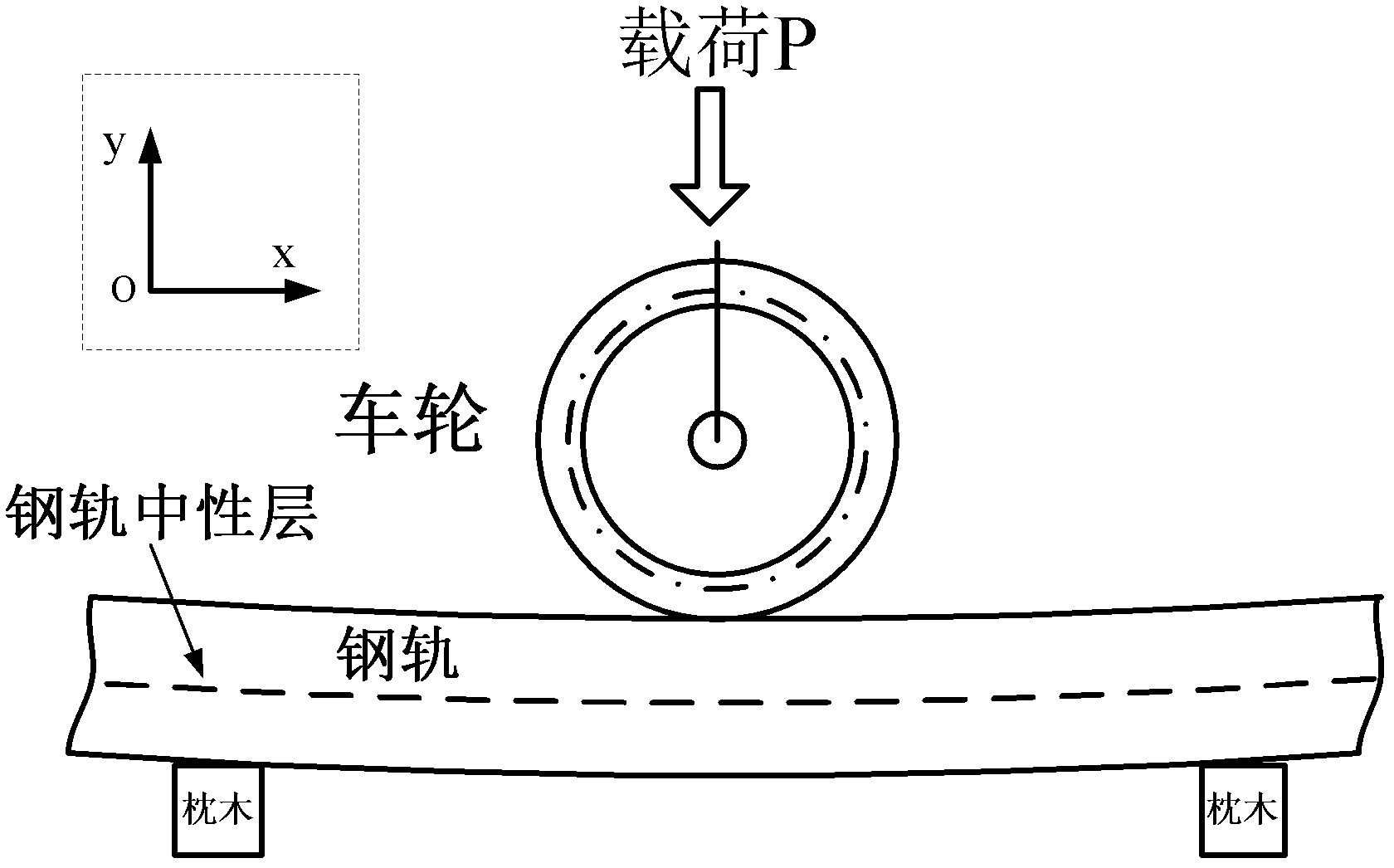

[0023] figure 1 It is a schematic diagram of the structure principle of the entire sensing system adopted when the present invention is implemented. The broadband light source (101) emits a light beam, which can be an ASE or SLED laser. Its typical bandwidth is tens of nanometers, and the reflection spectrum width of the fiber grating sensor is generally 0.2 nm ~ 0.3nm, so in conventional FBG sensing applications, it can be considered that the light source spectrum is much larger than the FBG reflection spectrum bandwidth. The light beam emitted by the light source enters the first sensing grating FBG1 (103) through the circulator 102, and the sensing grating FBG1 (103) reflects the light beam back to a narrow-band light, which is used as signal light and enters the second sensor grating through the circulator 102 A sensing grating FBG2 (104), enters the photodetector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com