Detector for sealing performance of hydraulic actuating element of automatic speed changer and detection method thereof

A technology of hydraulic actuators and automatic transmissions, which can be used in the use of liquid/vacuum for liquid tightness measurement, and by measuring the acceleration and deceleration rates of fluids, etc., which can solve problems such as hydraulic leakage, invisible and intangible, personal safety threats, etc. To achieve the effect of improving work efficiency, improving accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings, and this manufacturing technique is clear to those skilled in the art.

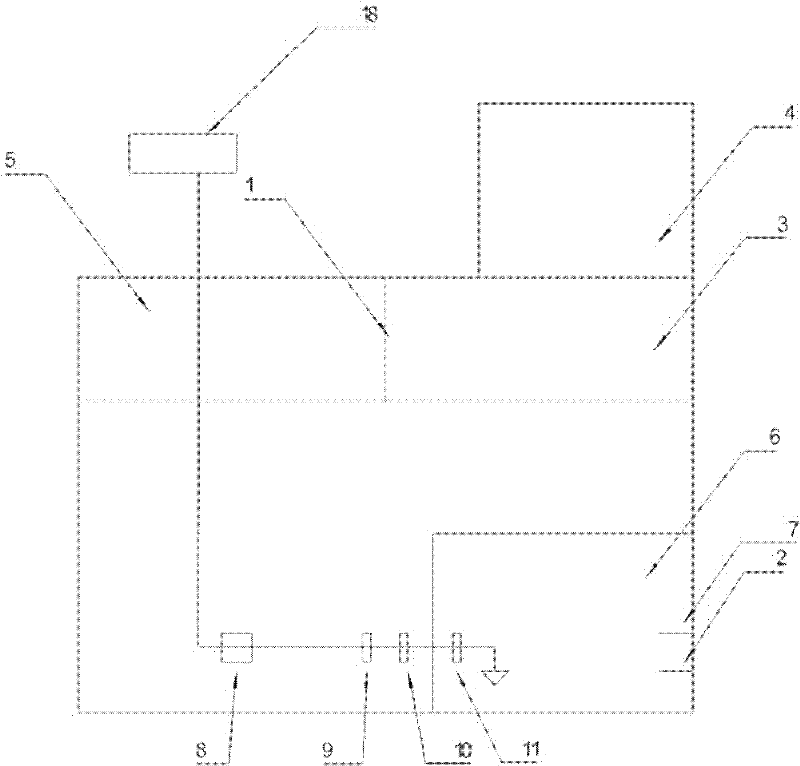

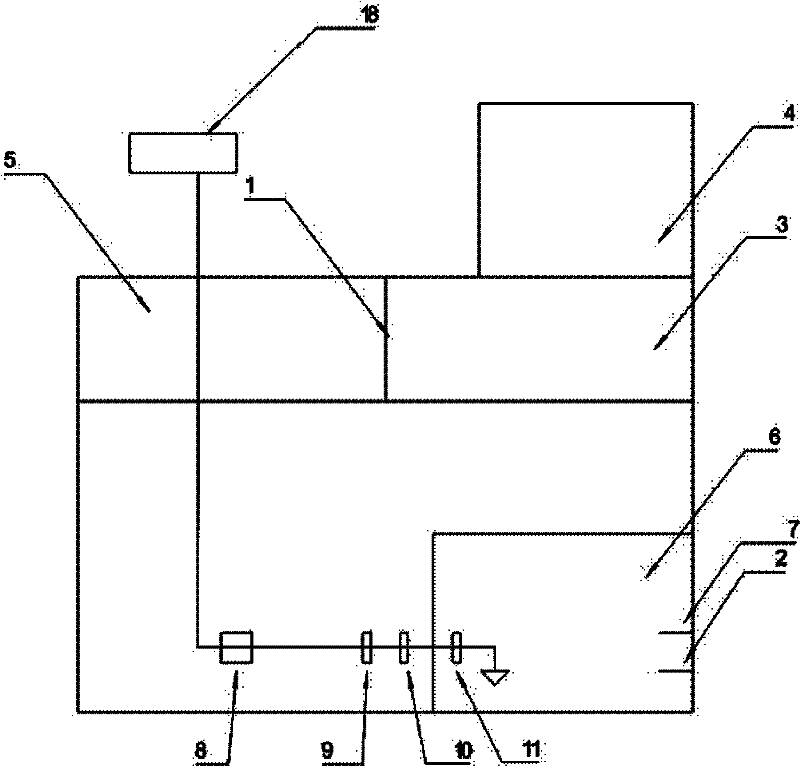

[0015] Such as figure 1 As shown, the automatic transmission hydraulic actuator sealing performance testing machine is composed of a chassis hydraulic device, a heater, and a pressure distributor. An industrial computer and a display are installed on the upper right of the chassis, and an electronic control device is installed on the upper left of the chassis. The lower right of the chassis is equipped with Fuel tank, a temperature transmitter and a heater are respectively installed on the right side of the fuel tank, and a motor, a coupling, a pressure regulating plate and an oil pump in the fuel tank are sequentially installed outside the left side of the fuel tank. A frequency converter is installed on the motor, and a signal input line of the frequency converter is connected to a compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com