Food quality detection system and detection method based on electronic nose

A quality inspection, electronic nose technology, applied in the direction of material resistance, can solve the problems of unsolved gas sensor baseline drift, single detection data processing method, limiting the role of electronic nose technology, etc., achieving light weight, solving baseline drift, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

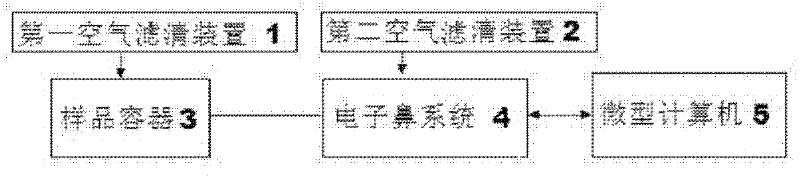

[0054] Such as figure 1 As shown, the food quality detection system based on the electronic nose of the present embodiment includes an electronic nose system, an air filter device and a microcomputer, and also includes a sample container 3, and the air filter device includes a first air filter device 1 and a second air filter device. Two air filter devices 2; the electronic nose system 4 is connected with the microcomputer 5; the first air filter device is connected with the sample container, and the second air filter device is connected with the electronic nose system.

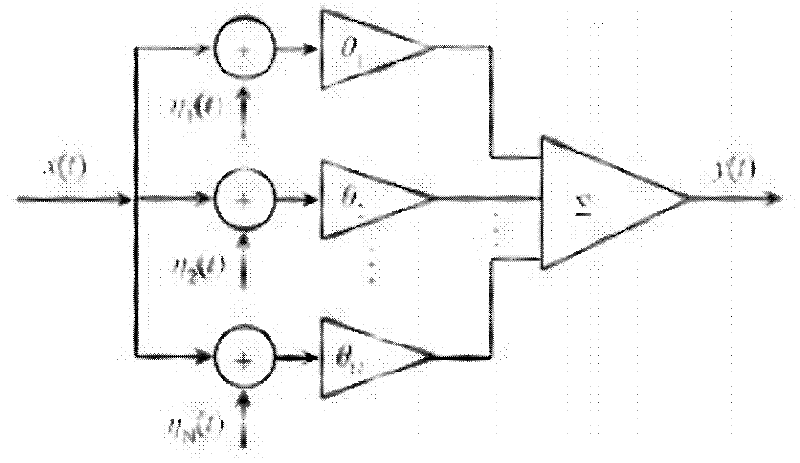

[0055] The microcomputer is equipped with host computer control software for controlling the electronic nose system to set working parameters, sample detection, sensor cleaning and experimental data collection, processing and analysis. The electronic nose system includes a sensor array, an air supply power unit and several air chambers. The sensor array includes 8 gas sensors; each sensor is in an indep...

Embodiment 2

[0078] The structural part in embodiment 2 is identical with embodiment 1, in embodiment 1

[0079] Insert the following steps between said step (7) and step (8):

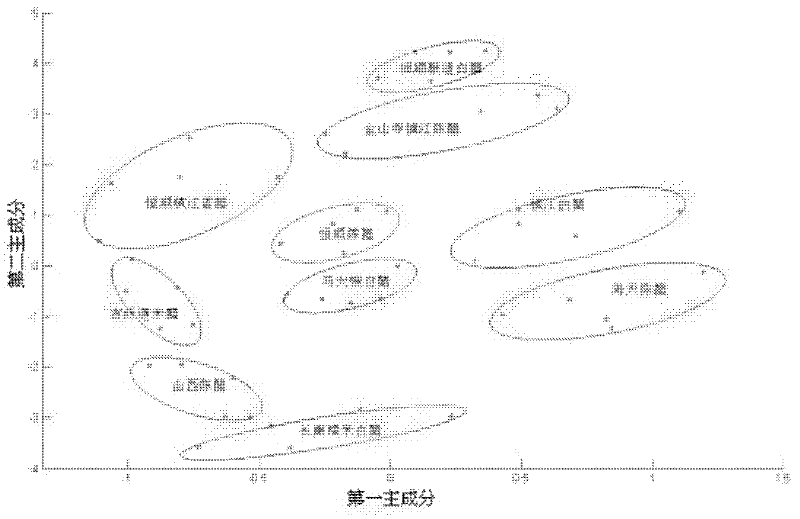

[0080] Such as Figure 9 As shown, different food quality prediction models are fitted according to the cross-correlation coefficient eigenvalue foe of different quality foods;

[0081] Substitute the eigenvalue foe of the cross-correlation coefficient into the formula of the following milk quality prediction model to calculate the food quality coefficient:

[0082]

[0083] Among them, foe is the eigenvalue of the cross-correlation coefficient, is the food quality factor.

[0084] Judging food quality based on milk quality coefficient.

[0085] Detect pure milk samples mixed with different proportions of milk powder:

[0086] The detection principle of the semiconductor gas sensor is the change of electrical properties caused by the combination of sensitive materials and milk volatile gas components,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com