Experimental device for simulating spreading of propping agent in crack and application thereof

An experimental device and proppant technology, applied in the field of oil and gas field development and research, can solve problems such as roughness, small size, and no consideration of fracture walls, and achieve the effect of reliable measured data and large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

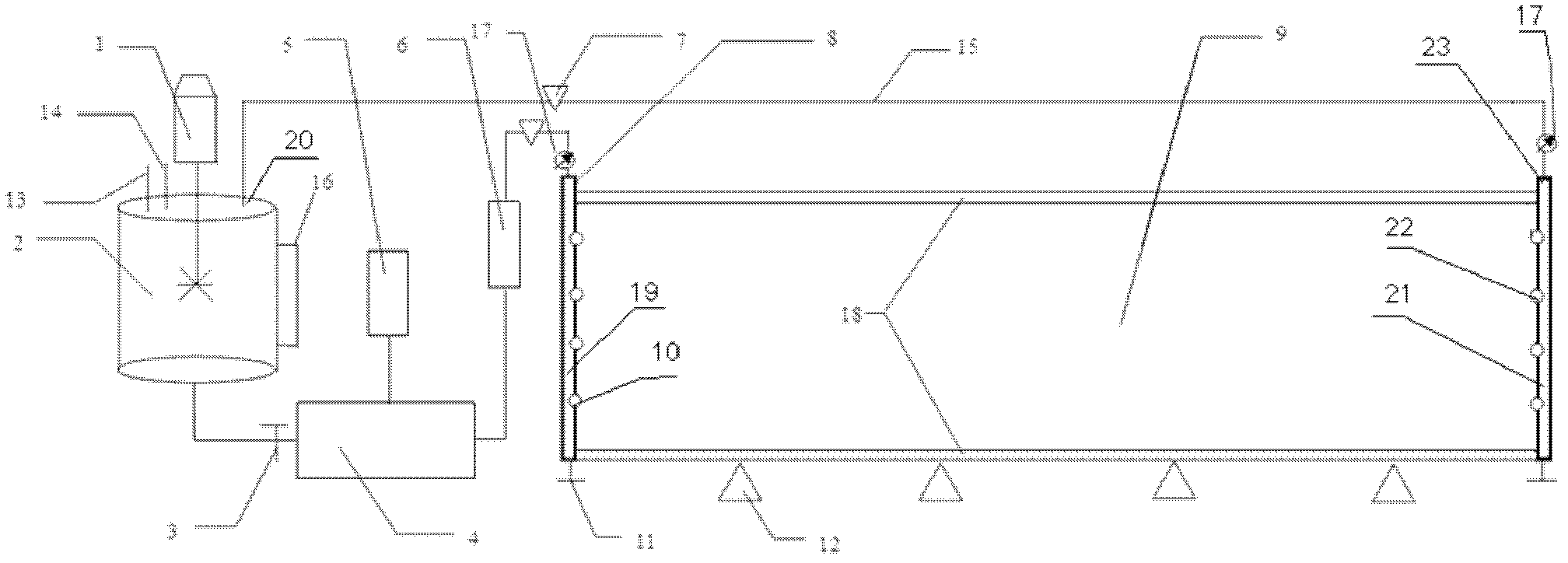

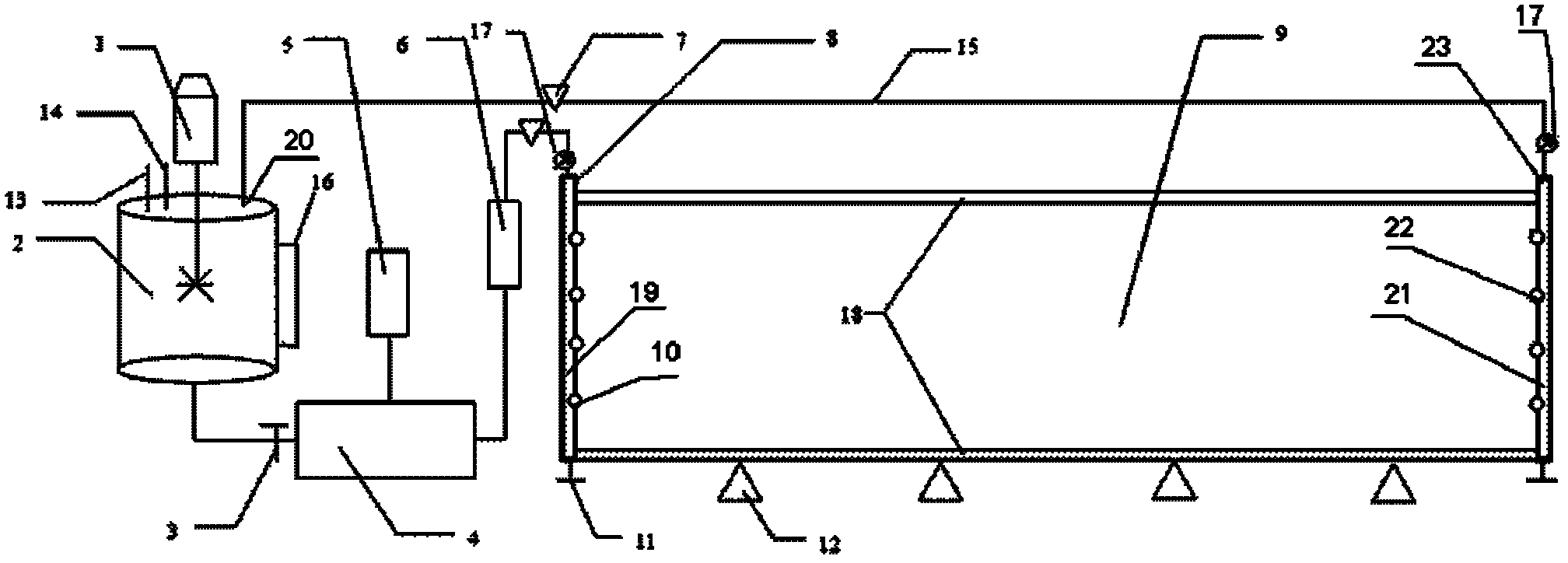

[0051] Such as figure 1 As shown, an experimental device for simulating the laying of proppants in fractures includes artificial fractures. The artificial fractures include two transparent flat plates 9 arranged parallel to each other. The upper and lower ends of the two transparent flat plates 9 are respectively wrapped Frame 18 is sealed, and a simulated shaft 19 is set at the left end of the transparent plate, and a liquid outlet pipe 21 is set at the right end of the transparent plate 9, and the transparent plate 9, the frame 18, the 19 cylinder walls of the simulated well shaft and the liquid outlet pipe 21 The cylinder walls together form a closed space; the top of the simulated wellbore 19 is provided with a feed port 8, the bottom of the simulated wellbore 19 is provided with a discharge port 11, and a plurality of cylinders are uniformly arranged on the simulated wellbore wall and toward the direction of the confined space. Wall perforation 10, the feed port 8, discha...

Embodiment 2

[0057] An experimental method utilizing the experimental device described in Example 1 to simulate proppant laying in a fracture, the steps are as follows:

[0058] (1) According to the principle of similarity, according to the width and size of the fracture in the field construction, calculate the proppant dose, fracturing fluid volume, fracturing fluid viscosity and experimental displacement required for the experiment;

[0059] (2) Calculate the required proppant dose, fracturing fluid volume and experimental displacement, fracturing fluid and various proppants according to the calculation in step (1);

[0060] (3) Adjust the distance between the two transparent plates 9 in the artificial fracture to make it consistent with the width of the fracture in the field construction; adjust the number of perforations on the wall of the simulated wellbore, the aperture of the perforation on the wall and the perforation on the wall The phase angle of the cylinder wall: the number of ...

Embodiment 3

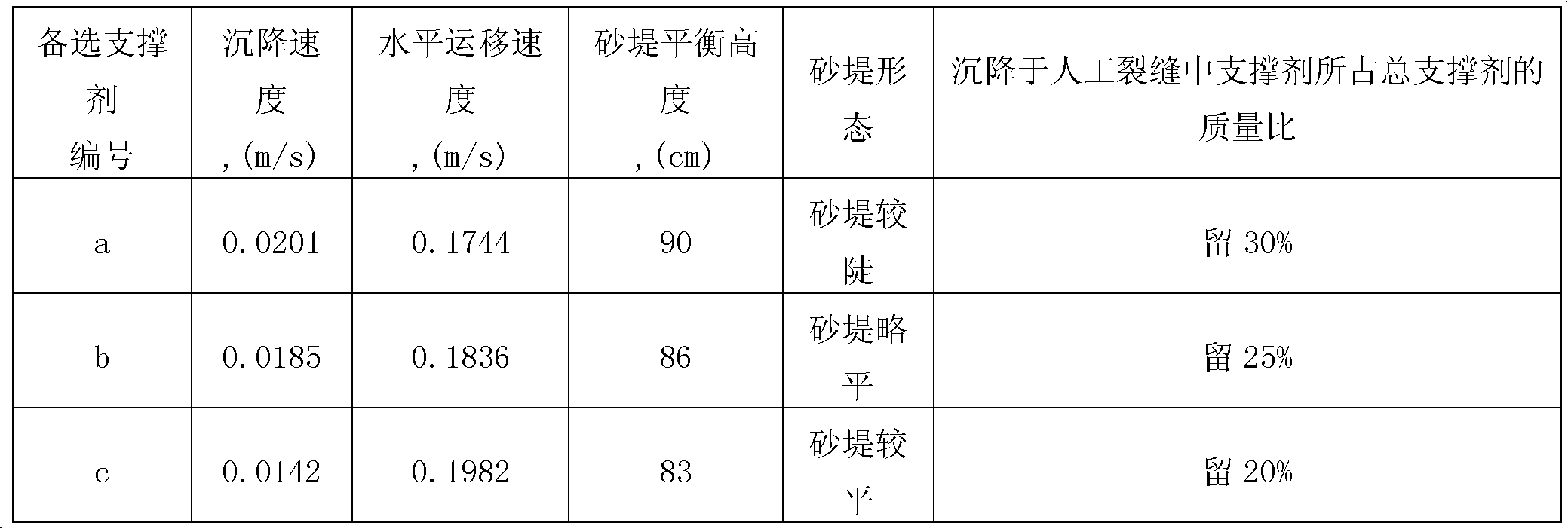

[0067] An experimental device as described in Embodiment 1, the difference is that the experimental device also includes a data acquisition control board and a computer, and the experimental data collected by the experimental device is transmitted to the computer through the data acquisition control board. The experimental data include the vertical settlement velocity and horizontal migration velocity of the proppant, the velocity and shape of the sand bank formed by the proppant settlement in the artificial fracture, the mass ratio of the proppant settled in the artificial fracture to the total proppant, etc. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com