Wire arrangement structure for single-layer indium tin oxide (ITO)

A wiring structure, single-layer technology, applied in the field of single-layer ITO wiring structure, can solve the problems of increased touch screen thickness, low product yield, high cost, etc., to improve edge accuracy and linearity, good sensing ability, simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and an embodiment.

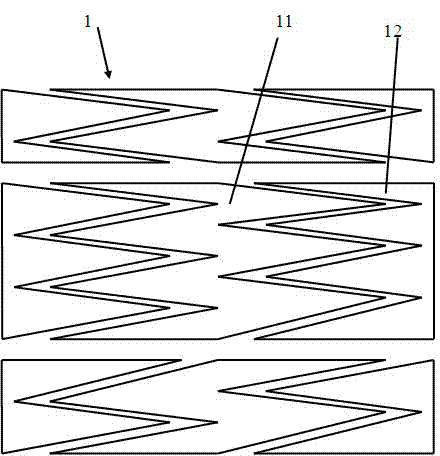

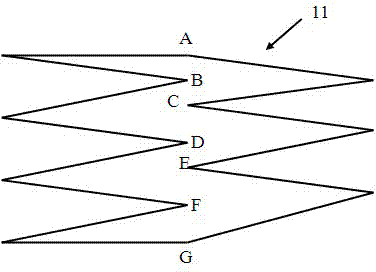

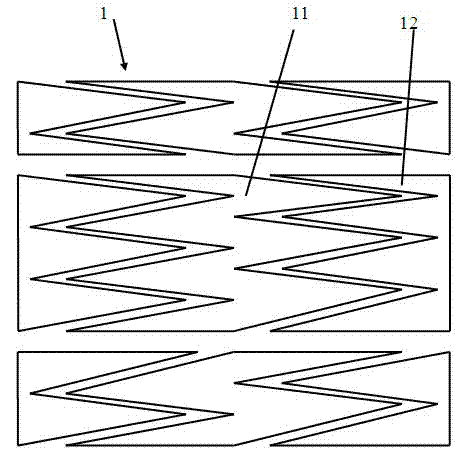

[0011] Please refer to figure 1 As shown, the present invention relates to a single-layer ITO wiring structure, in which two types of touch electrodes 11 and 12 are arranged on the ITO layer 1, the first touch electrode 12 is in a unidirectional zigzag shape, and the second touch electrode 12 is in a zigzag shape. The two types of touch electrodes 11 are in a bidirectional zigzag shape, at least one of the second type of touch electrodes 11 is arranged in the gap between the two first type of touch electrodes 12, and between two adjacent electrodes The zigzags between them are engaged with each other, and the intersection points between every two adjacent teeth in the same direction on the second type touch electrode 11 fall on the same straight line.

[0012] The first-type touch electrodes 12 are arranged around the edges of the ITO layer 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com