Dual-simplified pulse coupled neural network-based grey cloth defect division method

A technology of pulse-coupled nerves and defects, applied in image data processing, instruments, calculations, etc., can solve the problems of multiple adjustment parameters and high computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

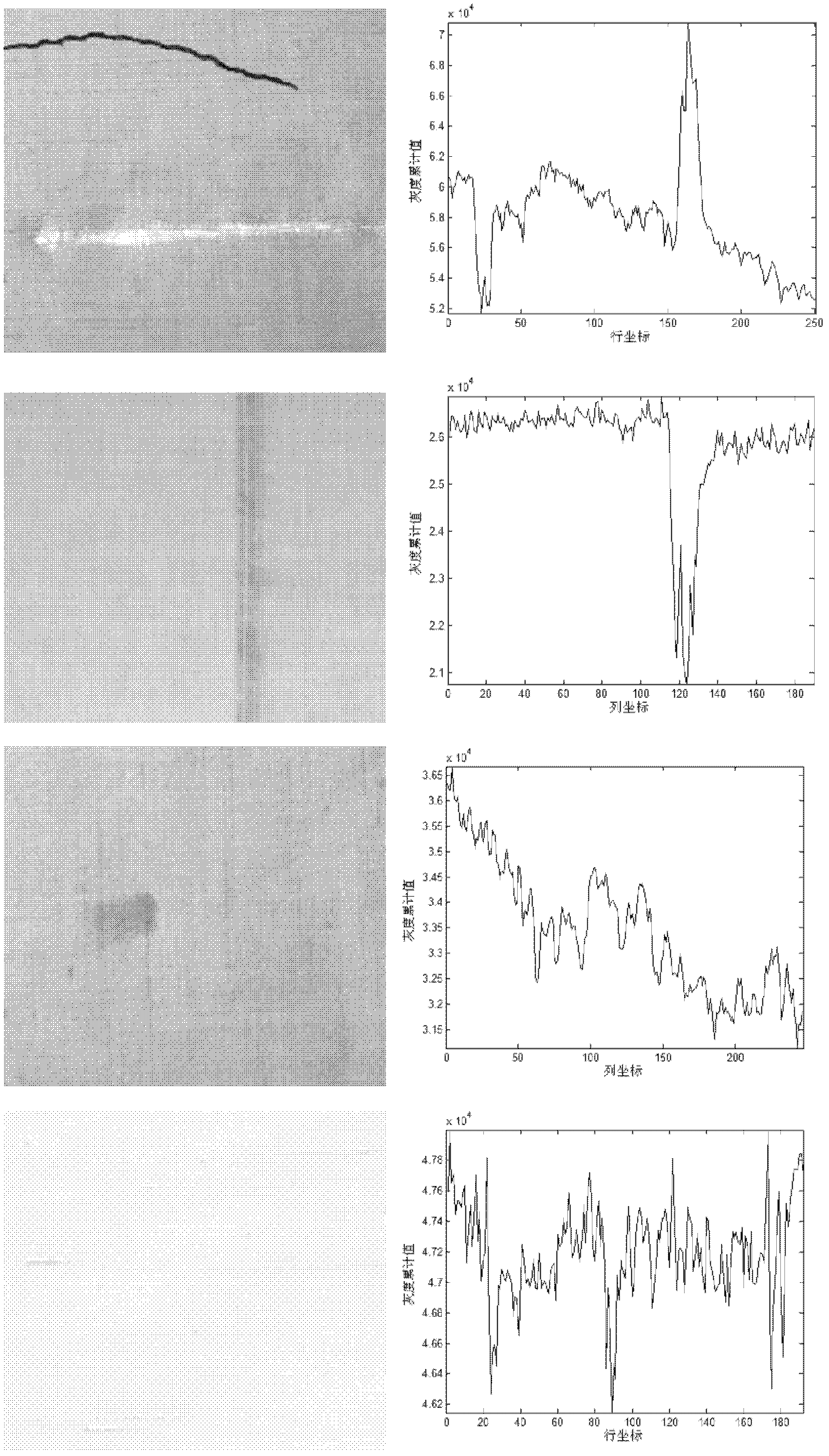

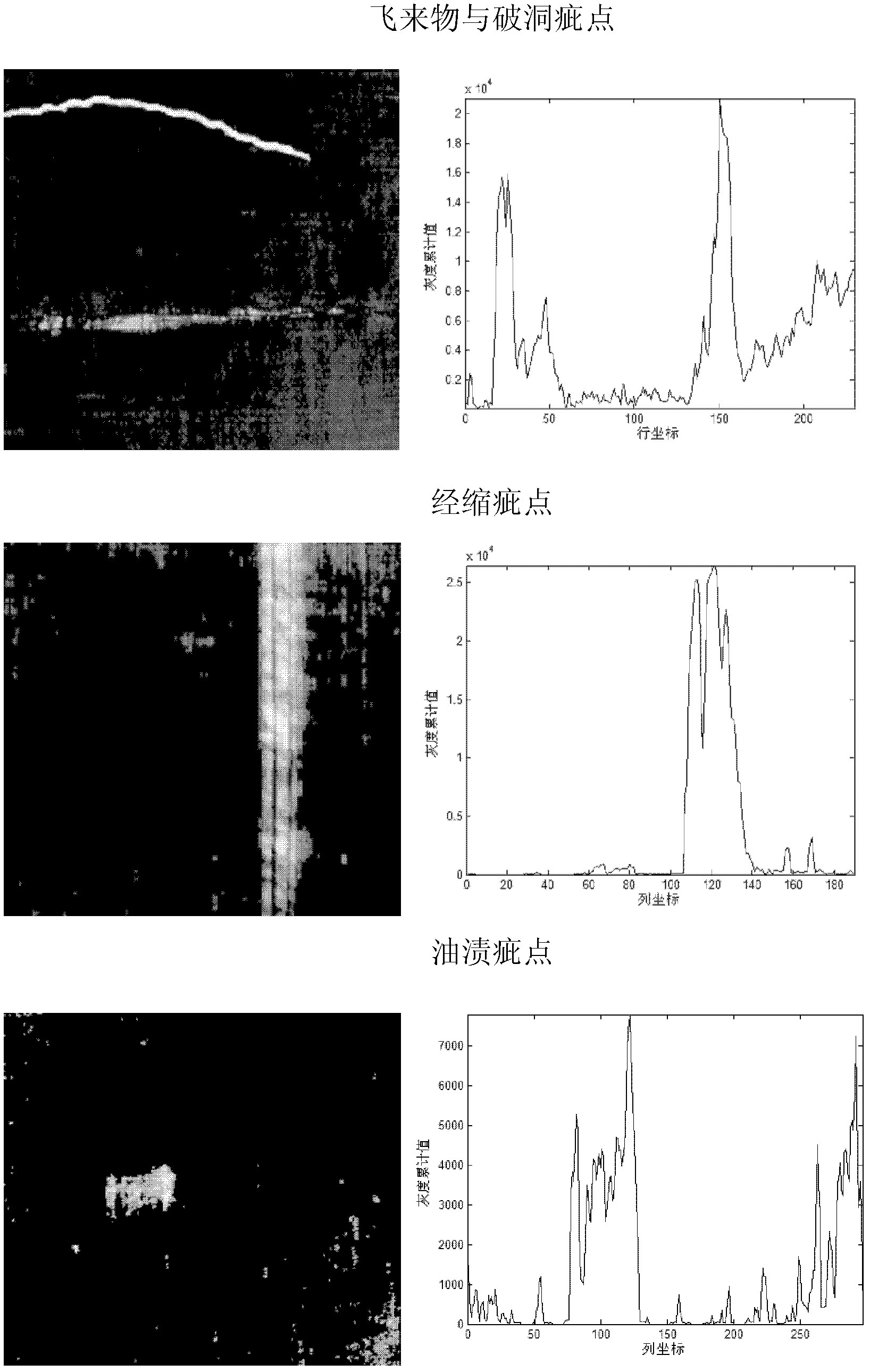

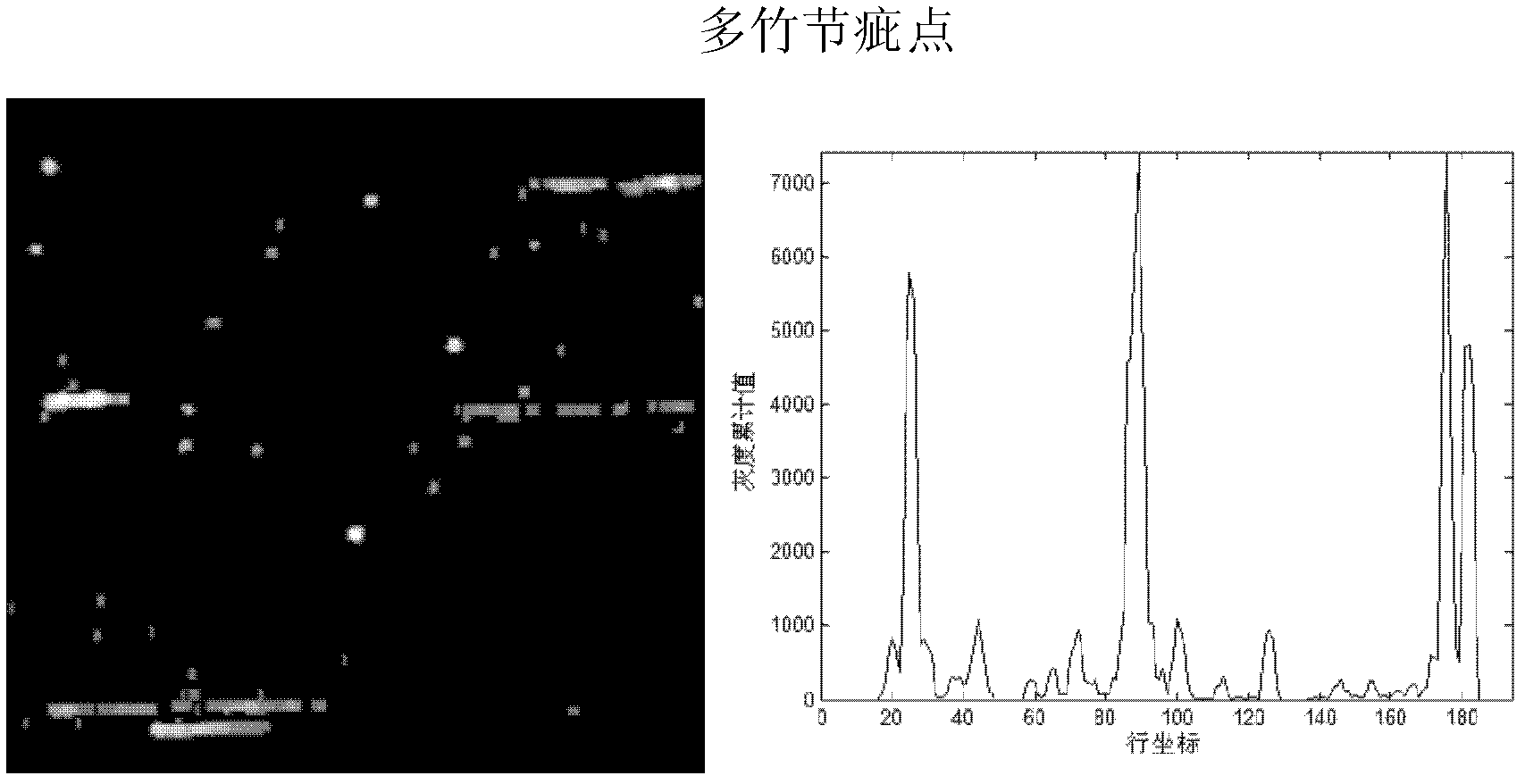

[0050] The principle of the method of the present invention is that firstly, the original digital image of the gray cloth to be tested with the size of M×N collected by the camera is divided into non-overlapping windows of the size of n×n; The local binary modulus sum corresponding to the variability of the average attribute value of the row and column pixels, and then calculate the binary modulus difference between the row and column as the feature value in the window, and obtain a The characteristic image of the gray cloth to be tested in the size. Then, divide the feature image of K×L size into overlapping windows of m×m size, each pixel in the image corresponds to each neuron in DSPCNN, and the attribute intensity value of the pixel g ij As the neuron external stimulus input N ij , according to the characteristics of human vision, unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com