Velocity sensorless vector control method for single bus current detection of three-phase alternating-current motor

A speed sensorless, DC bus current technology, used in vector control systems, motor generator control, electronic commutated motor control, etc., to solve problems such as errors and current waveform distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

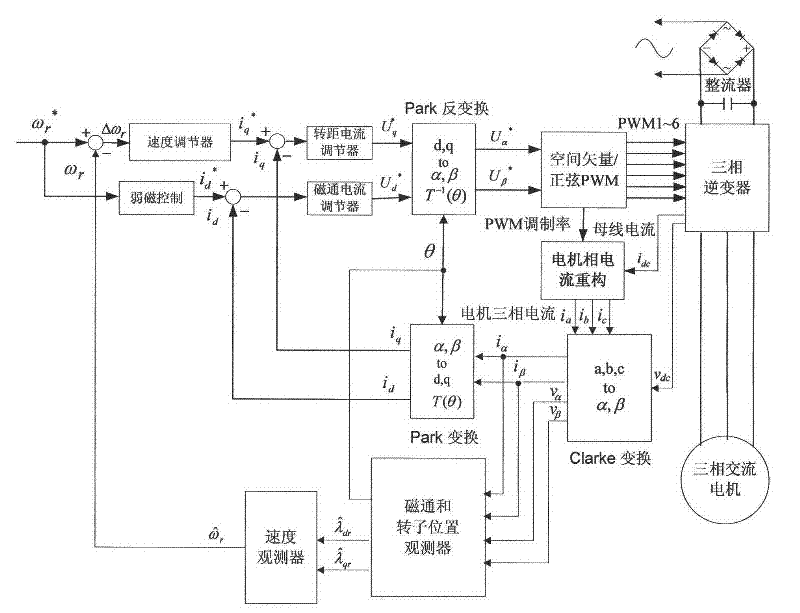

[0026] In order to realize the speed sensorless vector control method of single busbar current detection for three-phase AC motors of the present invention, the specific implementation process includes:

[0027] (1) Hardware circuit settings;

[0028] First, a specific introduction to the hardware circuits involved in the scheme of the present invention.

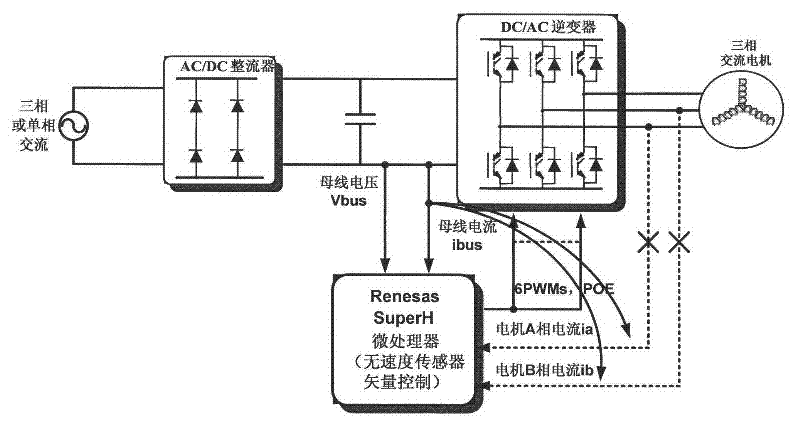

[0029] Such as figure 1 As shown, the system mainly includes a voltage source inverter (VSI) composed of an AC to DC rectifier, a DC bus and a DC to AC inverter, and a controller with a microprocessor as the central processing unit. The voltage source inverter is used to provide a three-phase power supply with adjustable frequency and voltage to the motor. The controller is used to realize the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com