Coated glass sheet

A glass plate, coating technology, applied in coating, thin material handling, transportation and packaging, etc., can solve problems such as damage to the first layer and poor resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17

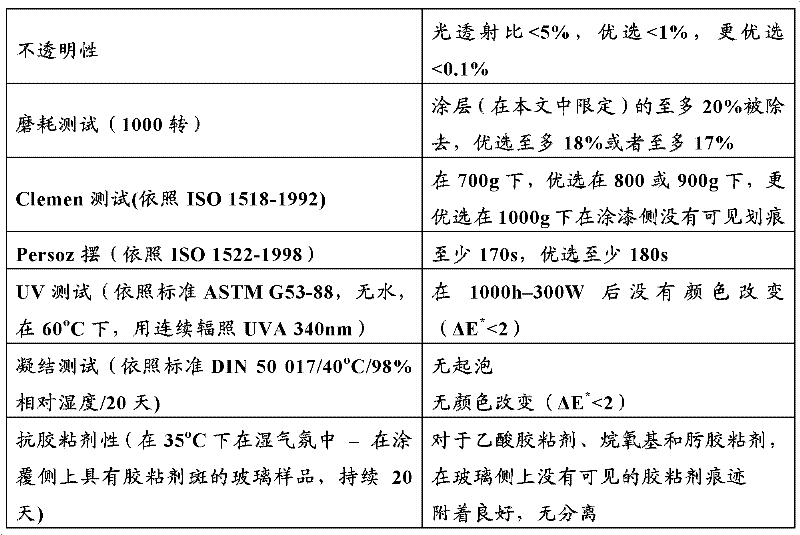

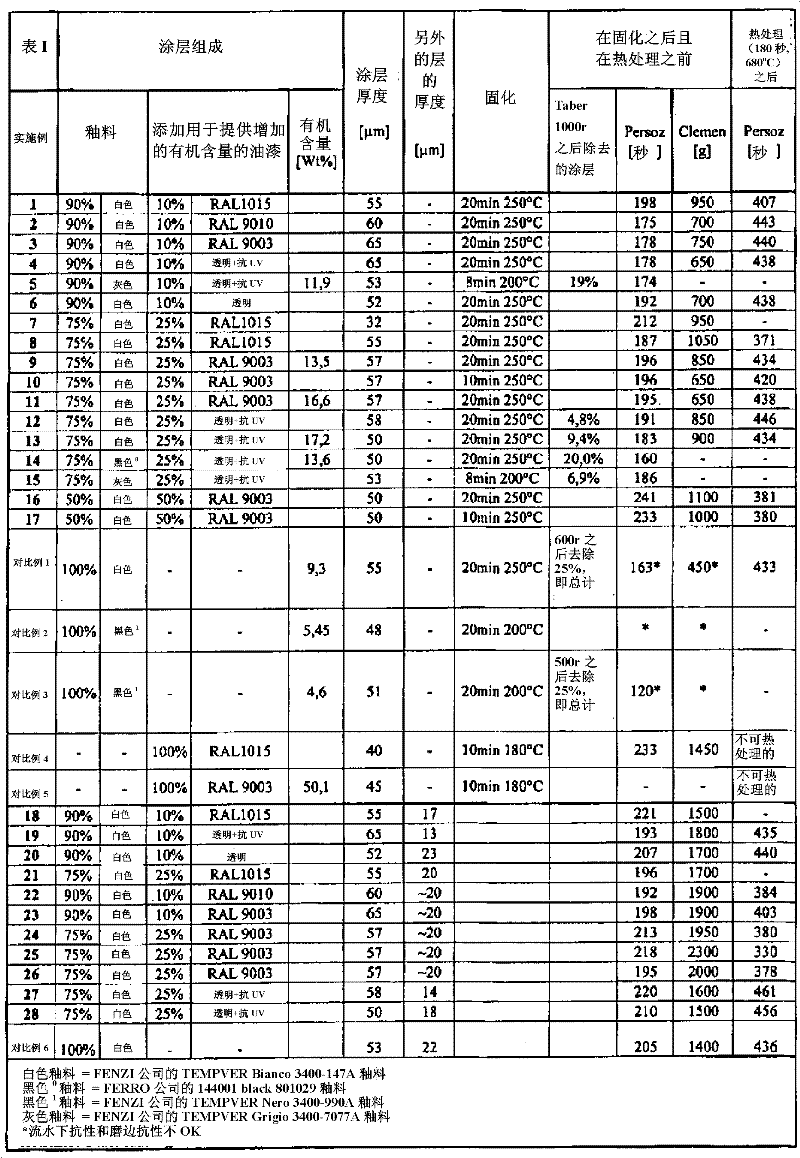

[0040] Various mixtures containing commercially available glazes and commercially available paints were produced. According to the invention, paint is added to provide increased organic matter content to the glaze.

[0041] The glazes used in all Examples 1-17 are shown in Table I. An example is the white glaze TEMPVER bianco 3400-147A from FENZI, which contains approximately 75% by weight glass frit and approximately 25% by weight organic matter (acrylic resin and plasticizer).

[0042] In examples 1-3, 7-11 and 16-17, GLASSOREX paints from the company FENZI were used, with various colors defined according to the RAL system. These paints typically contain approximately pigments, solvents, methacrylic resins, melamine resins, and epoxy resins. In examples 4-5 and 12-15, a clearcoat from the company FENZI containing anti-UV additives was used; in example 6, the clearcoat did not contain anti-UV additives. The clear coat may also contain methacrylic resins, melamine resins an...

Embodiment 18-28

[0052] The various coated and cured glasses according to the first set of examples were further coated by passing under a curtain coater in which polyurethane paint from the company FENZI containing about 50% by weight of glaze filler was applied to the first coat of glaze and paint. This second coating dries directly after application at 200° C. during approximately 20 minutes.

[0053] The thickness of this additional layer once cured and before heat treatment of the product is given in column 8 of Table I. The product once cured and prior to heat treatment exhibited increased resistance (columns 10-12 of Table I) compared to a product having a single layer comprising glaze and paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com