Exhaust gas turbocharger, motor vehicle, and method for assembling an exhaust gas turbocharger

A technology of exhaust gas turbine and supercharger, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., which can solve the problems of time-consuming installation and high cost, and achieve the effects of improving reliability, low-cost assembly, and reducing surface pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

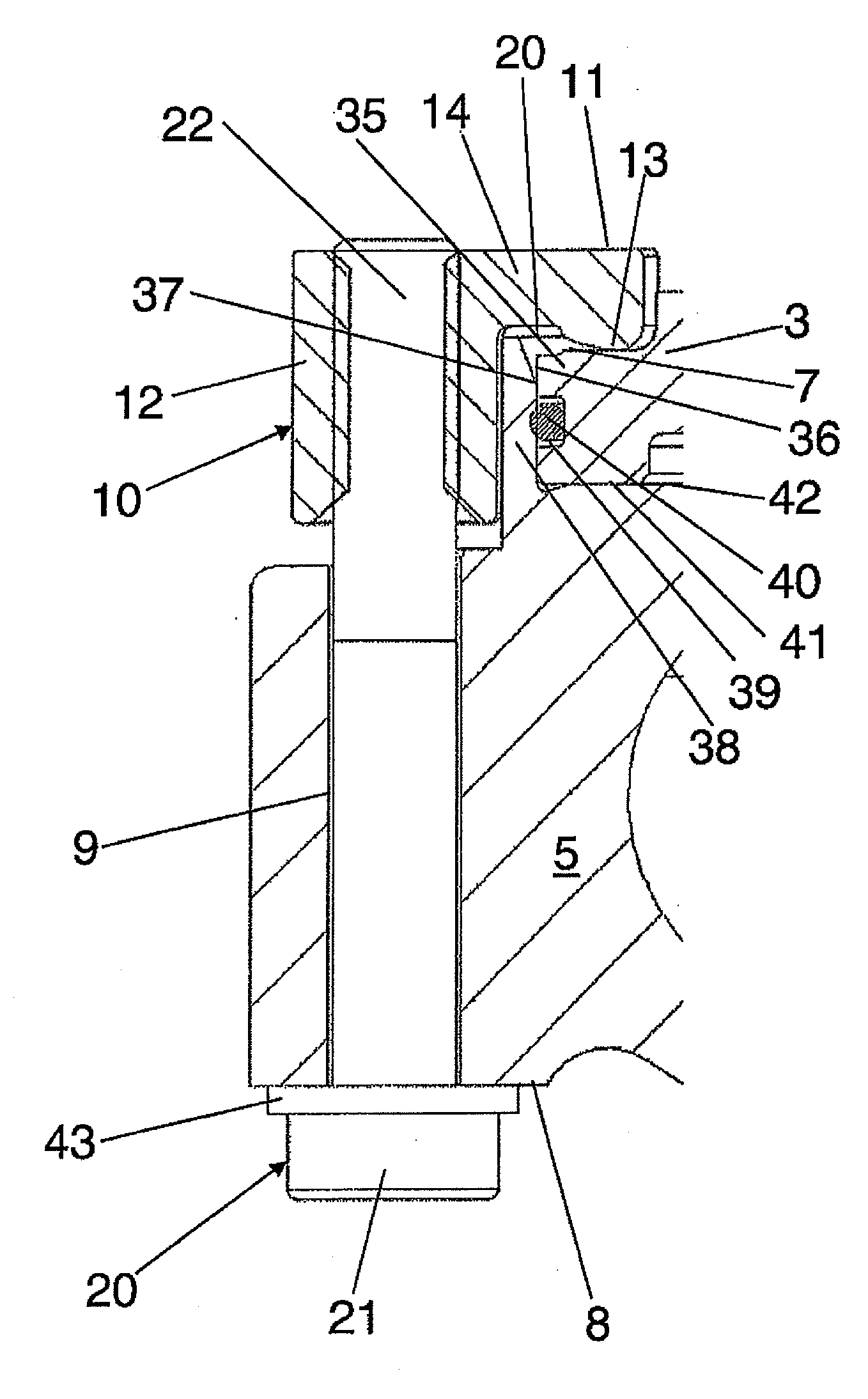

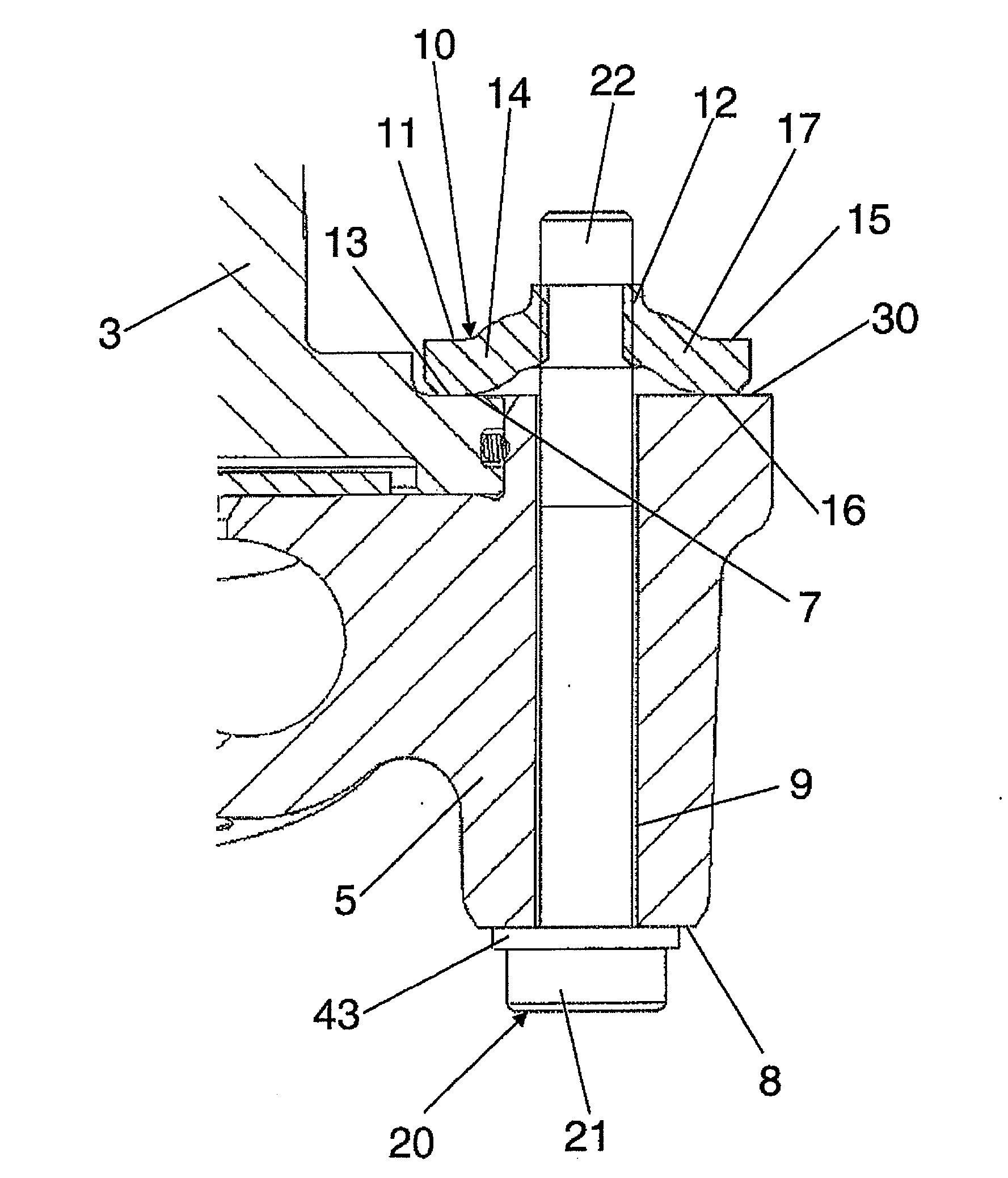

[0036] figure 1 A partial view of a cross-section of a preferred embodiment of the exhaust gas turbocharger according to the invention is shown.

[0037] figure 1 Firstly, two housing parts 3 , 5 are shown, which are designed as bearing housing 3 or compressor housing 5 of the exhaust gas turbocharger. The bearing housing 3 has a preferably annular bearing housing flange 35 with a preferably cylindrical outer surface 36 . Alternatively, the bearing housing flange 35 can also have a rectangular shape or any other geometric shape. The preferably cylindrical outer surface 36 guides on a correspondingly cylindrical inner surface 37 of the compressor housing flange. In an alternative embodiment of the exhaust gas turbocharger according to the invention, the bearing housing 3 is designed with a cylindrical inner surface and the compressor housing 5 is correspondingly designed with a cylindrical outer surface. The bearing housing flange 35 has a sealing ring groove 39 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com