Sample pretreatment method for tea leaf pesticide residue detection and tea leaf purification column

A sample pretreatment and pesticide residue technology, which is applied in the field of agricultural product safety testing and food hygiene, can solve problems such as complex tea ingredients, and achieve the effects of saving experimental operation time, simplifying economic and manual operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

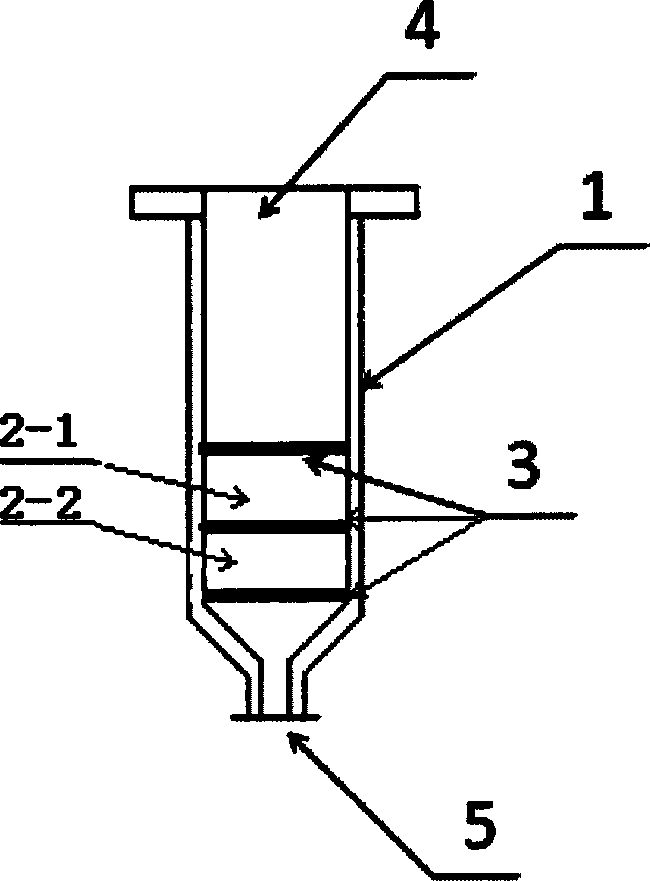

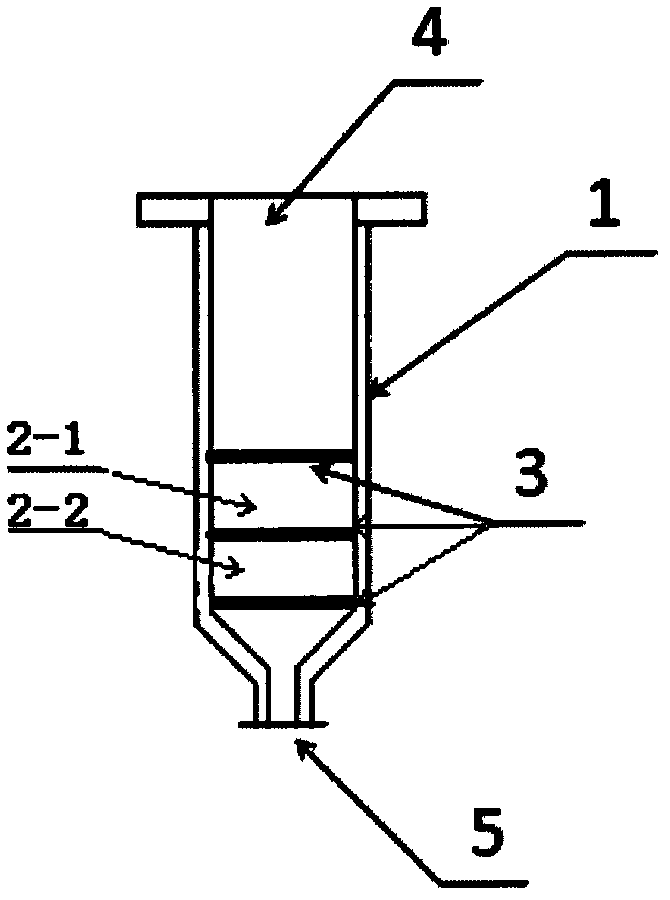

[0058] A tea purification column is prepared by a method comprising the following steps:

[0059] Use a high-density polyethylene column tube with a volume capacity of 6mL or 12mL, which is filled with graphitized carbon, aminated silica gel NH2, and amidated polyethylene divinylbenzene, among which aminated silica gel NH2 and amidated polyethylene divinylbenzene Mixed as a layer, graphitized carbon as a layer, a polypropylene sieve plate with a pore size of 20um is used as a separation, and a two-layer mixed purification column of three materials is used. In the tea purification column, graphitized carbon, aminated silica gel NH2 and The mass ratio of the three amidated polyethylene divinylbenzene materials is 8:8:1, and the graphitized carbon is packed in the bottom layer of the column tube.

Embodiment 2

[0061] A tea purification column is prepared by a method comprising the following steps:

[0062] Use a high-density polyethylene column tube with a volume capacity of 6mL or 12mL, which is filled with graphitized carbon, aminated silica gel NH2, and amidated polyethylene divinylbenzene, among which aminated silica gel NH2 and amidated polyethylene divinylbenzene Mixed as a layer, graphitized carbon as a layer, a polypropylene sieve plate with a pore size of 20um is used as a separation, and a two-layer mixed purification column of three materials is used. In the tea purification column, graphitized carbon, aminated silica gel NH2 and The mass ratio of the three materials of amidated polyethylene divinyl benzene is 6:4:1, and the graphitized carbon is packed at the bottom of the column tube.

Embodiment 3

[0064] A tea purification column is prepared by a method comprising the following steps:

[0065] Use a high-density polyethylene column tube with a volume capacity of 6mL or 12mL, which is filled with graphitized carbon, aminated silica gel NH2, and amidated polyethylene divinylbenzene, among which aminated silica gel NH2 and amidated polyethylene divinylbenzene Mixed as a layer, graphitized carbon as a layer, a polypropylene sieve plate with a pore size of 20um is used as a separation, and a two-layer mixed purification column of three materials is used. In the tea purification column, graphitized carbon, aminated silica gel NH2 and The mass ratio of the three materials of amidated polyethylene divinylbenzene is 5:4:1, and the graphitized carbon is packed at the bottom of the column tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com