Garbage separator, separating system and separating method

A separation system and separation machine technology, applied in solid separation, chemical instruments and methods, filtration and screening, etc., can solve problems such as low efficiency, high labor intensity of workers, and great health hazards of workers, and achieve good treatment effect, simple structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

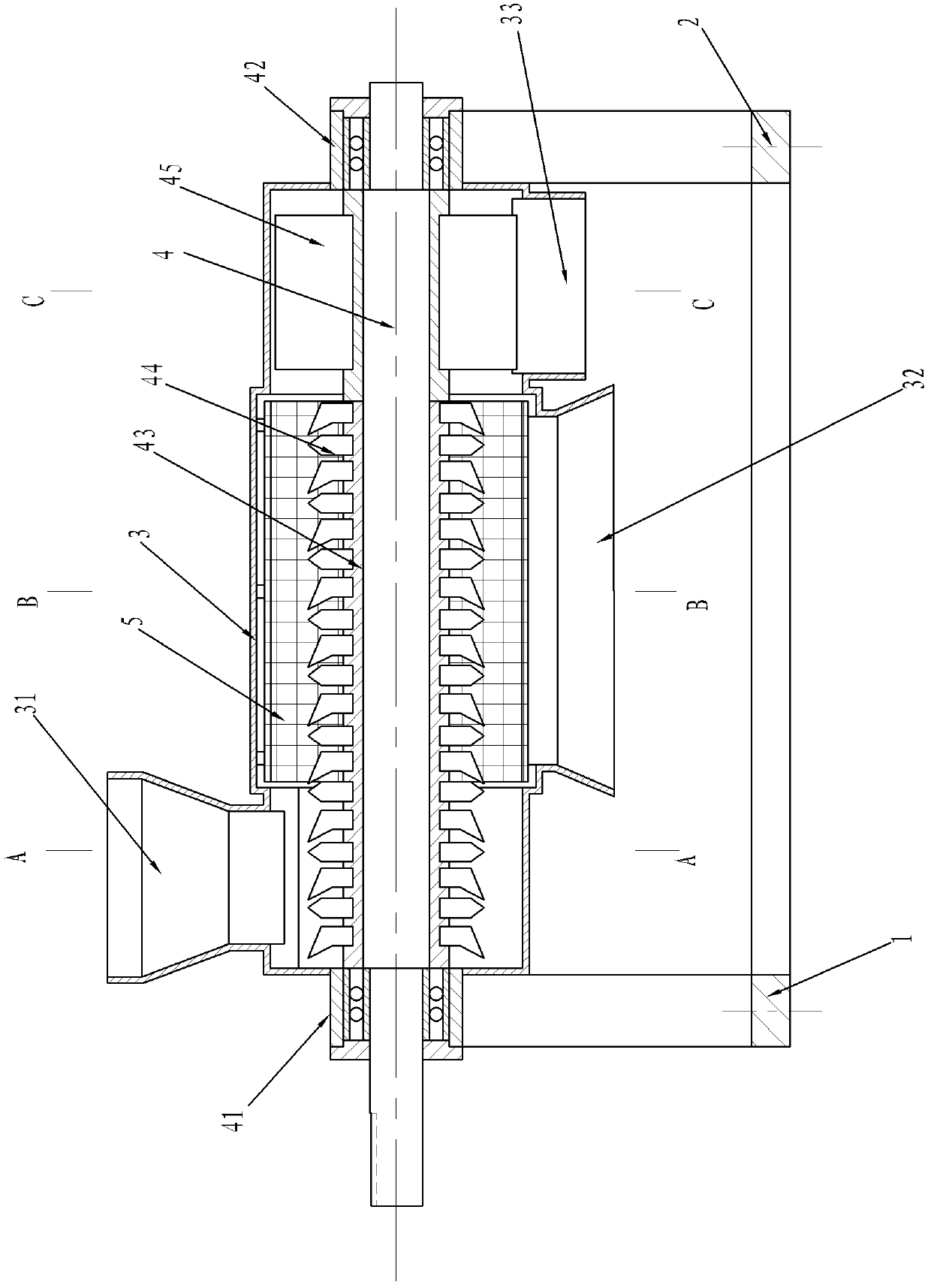

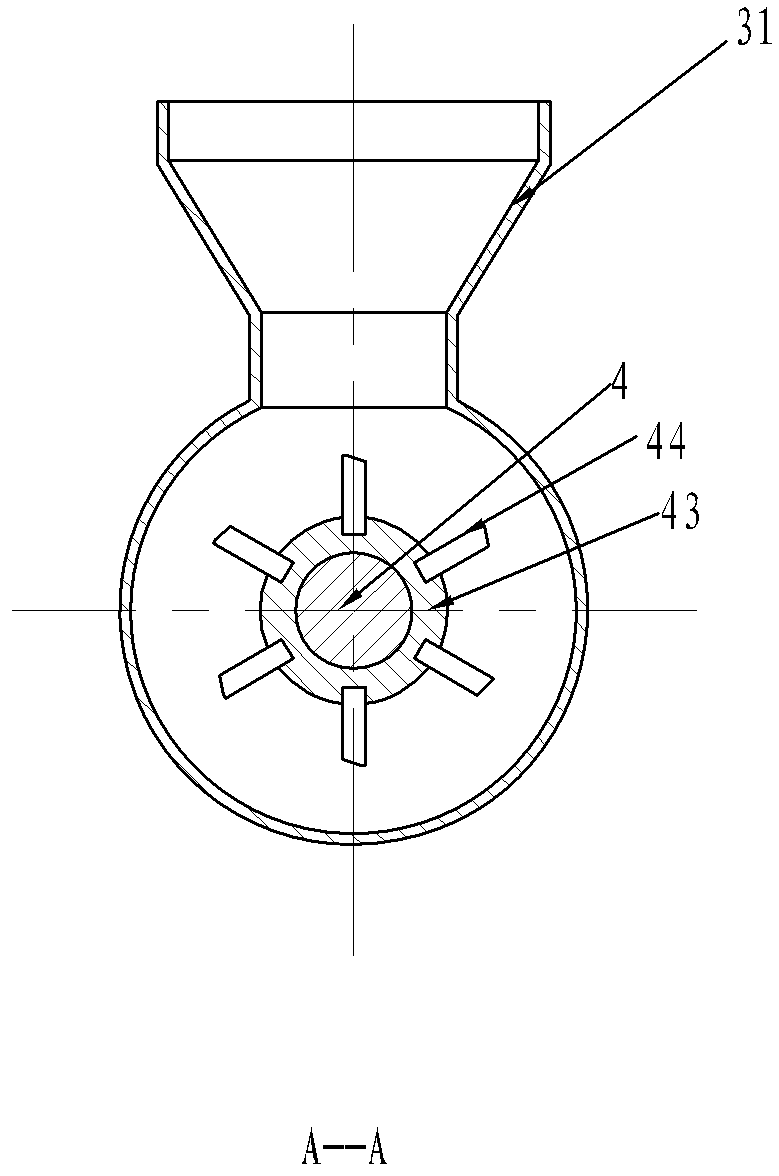

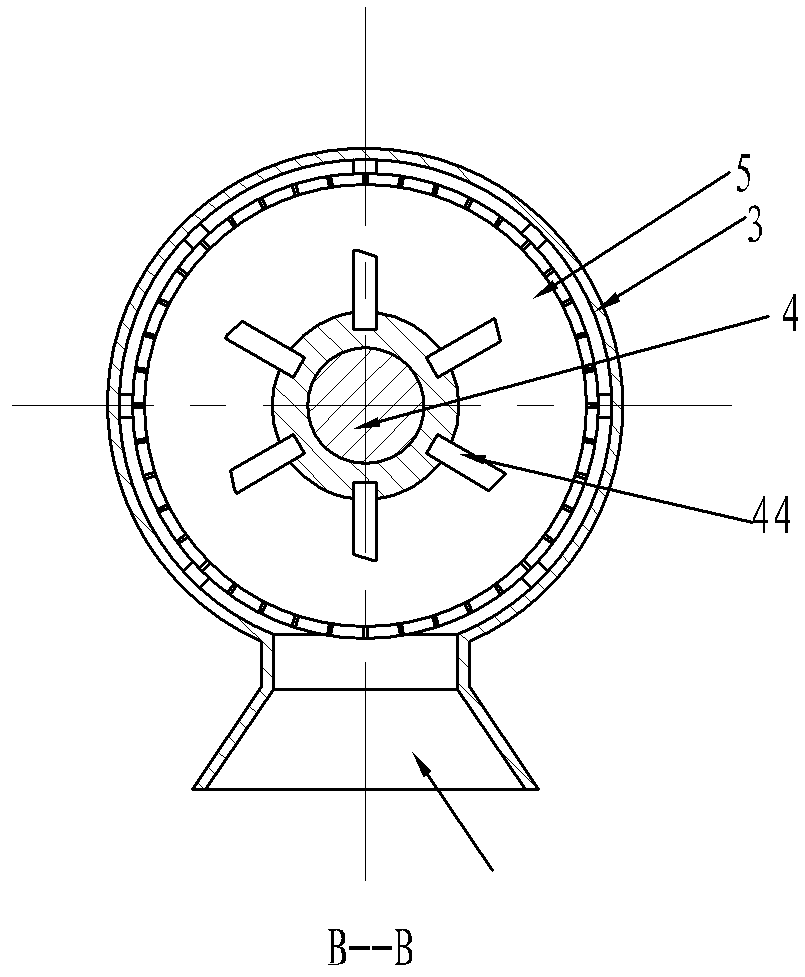

[0023] Such as Figure 1-4 As shown, the garbage separator of the present invention includes front and rear supports 1, 2, a separation chamber 3, a main shaft 4, and a sieve cylinder 5. The top of the front end of the separation chamber 3 is provided with a feed port 31, and the bottom of the separation chamber 3 middle part The first discharge port 32 is provided, the bottom of the separation chamber 3 rear end is provided with a second discharge port 33, the second discharge port 33 is fixed with a discharge guide plate 34, and the two ends of the main shaft 4 are installed on the front and rear respectively by bearings. In the rear bearing housing 41,42, the front and rear bearing housings 41,42 are respectively supported on the front and rear brackets 1,2, and the front and rear bearing housings 41,42 are fixedly connected with the two ends of the separation cavity 3 respectively, and the main shaft 4 Through the separation chamber 3, the middle part of the separation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com