Assembly and disassembly tool for locomotive brake shoe

A brake shoe and locomotive technology, which is applied in the field of locomotive brake shoe disassembly and assembly tools, can solve the problems of inconvenient operation, brake shoe breakage, narrow space, etc., and achieve the effects of avoiding industrial accidents, fixed force arm length, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

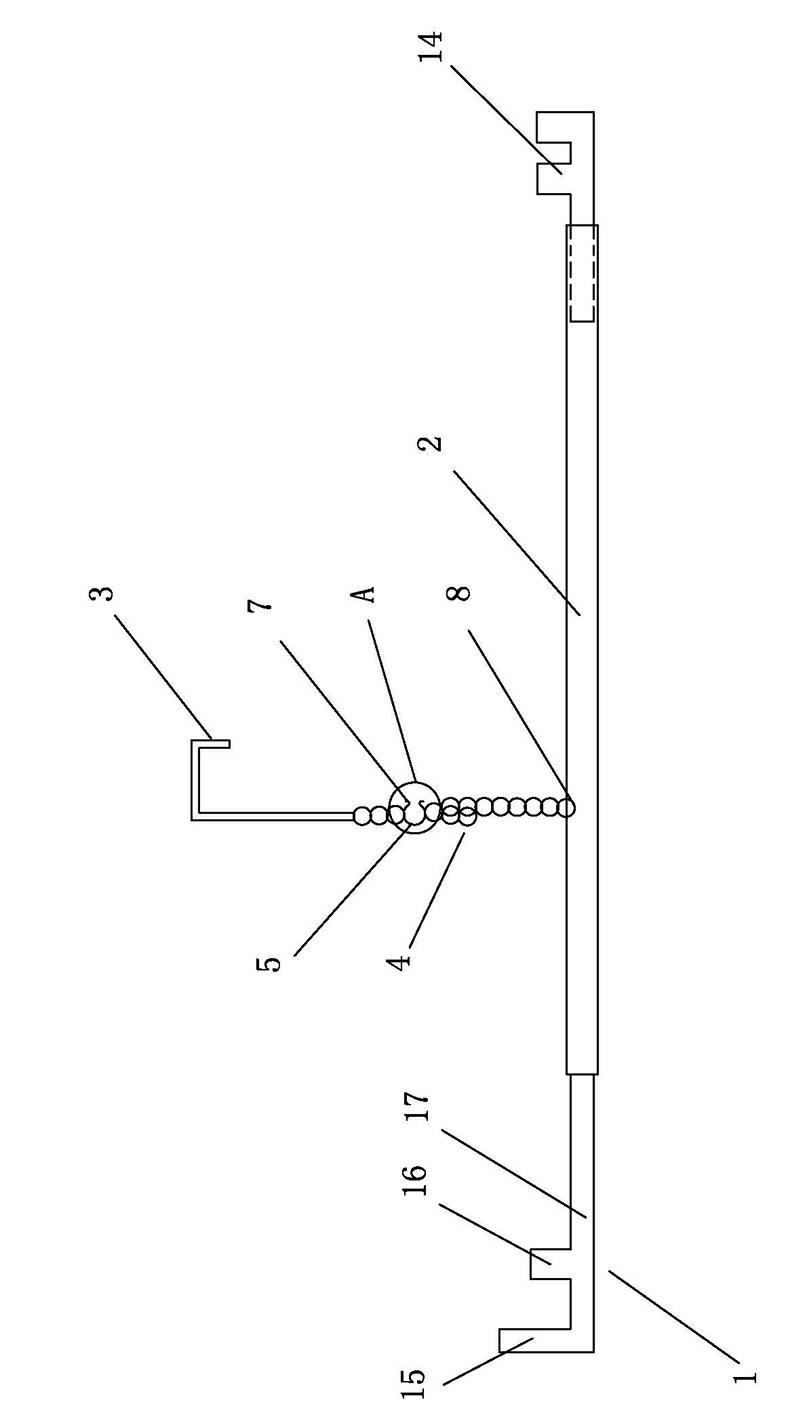

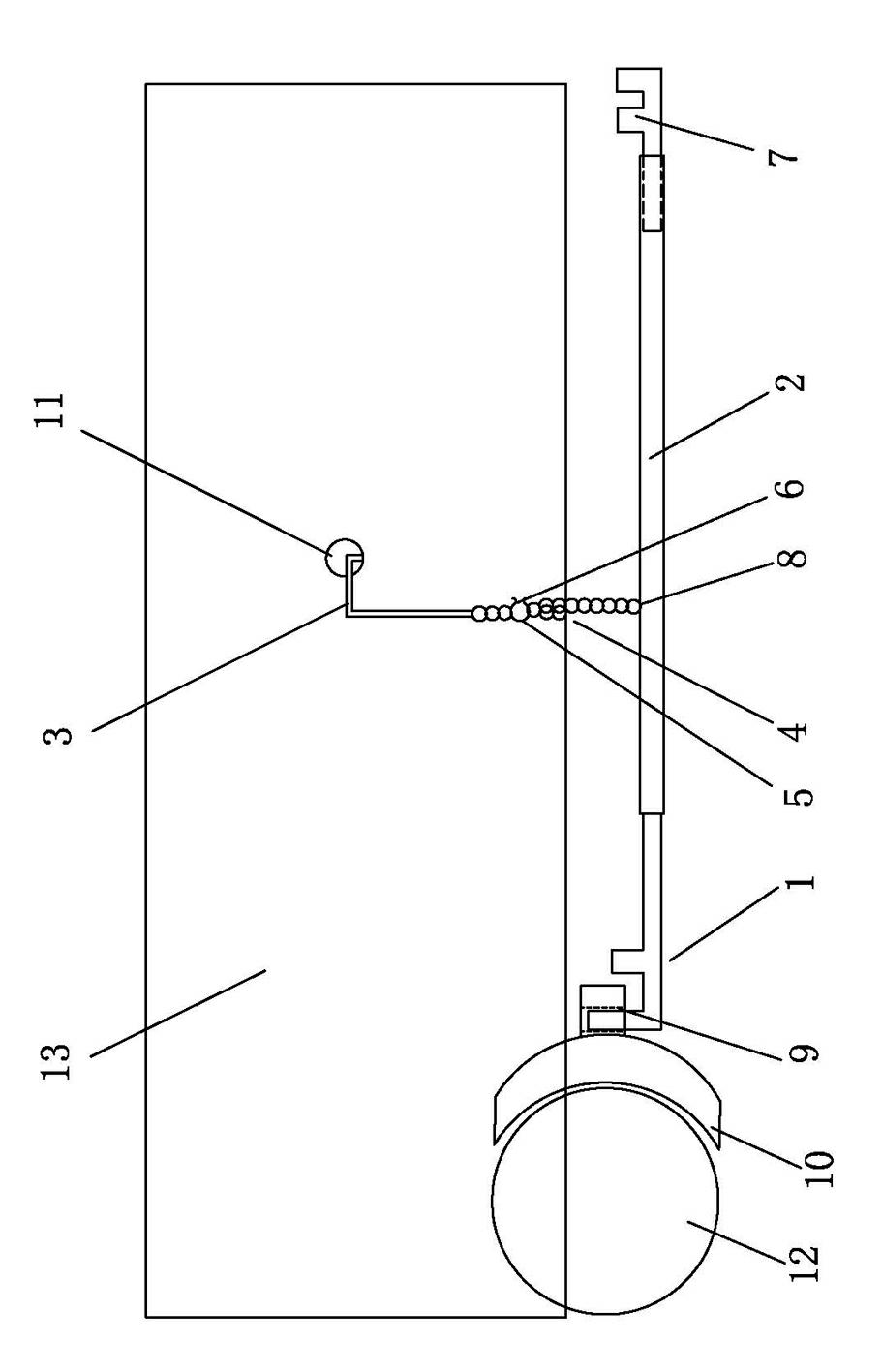

[0046] The described dismounting tool for locomotive brake shoe of the present invention, as figure 1 and figure 2 As shown, it includes a main body and a supporting part, the main body includes a hollow lever 2 and a brake shoe hook 1 with an "F" shape structure, and the brake shoe hook 1 with an "F" shape structure is fixedly connected to one end of the hollow lever 2;

[0047] The support part includes a chain ring group 4 and a hook body 3 , one end of the chain ring group 4 is welded to the hook body 3 , and the other end of the chain ring group 4 is welded to the hollow lever 2 . One end of the chain ring group 4 is directly welded to the hollow lever 2, so that the support part and the main body are connected firmly, and the length of the force arm of the hollow lever 2 is fixed, which is not easy to swing during use, and is convenient to use.

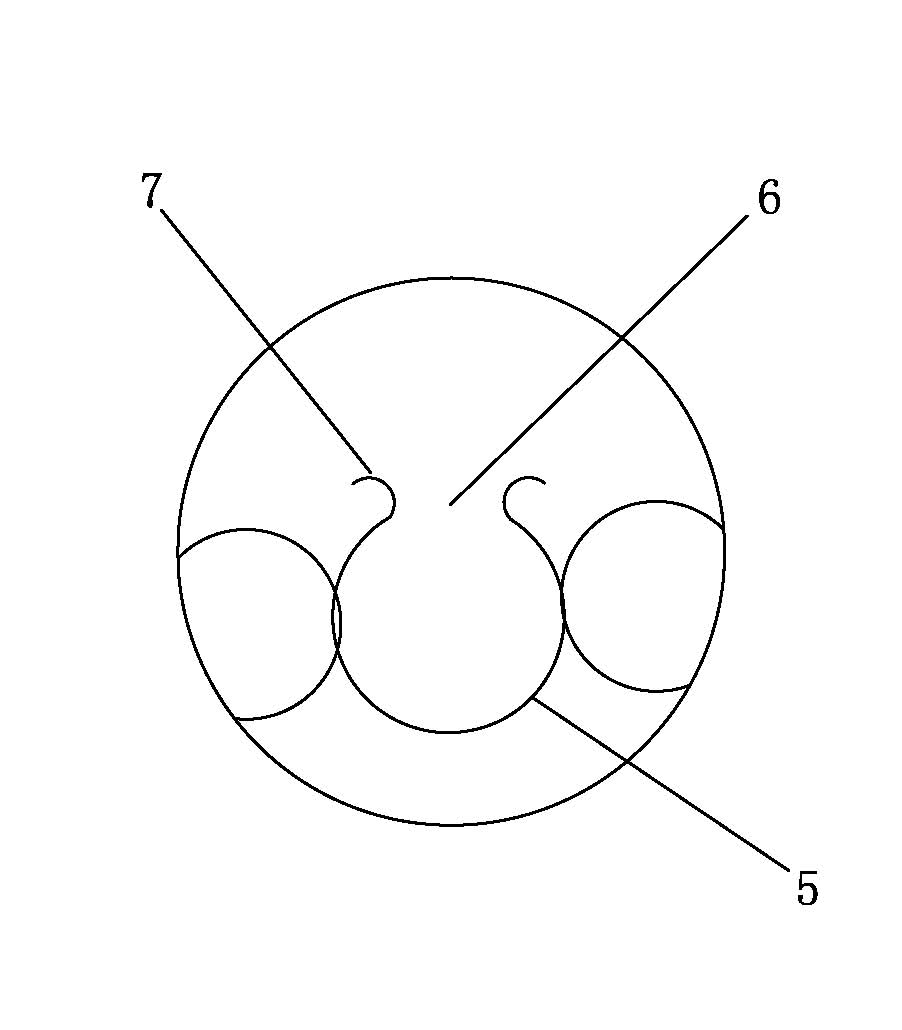

[0048] An adjustment chain ring 5 is arranged on the upper part of the chain ring group 4, and a gap 6 is provided in the mi...

Embodiment 2

[0073] The main technical solutions of the assembly and disassembly tool for locomotive brake shoes in this embodiment are the same as those in Embodiment 1. The features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0074] Such as figure 1 As shown, the distance between the welding point 8 where the other end of the chain ring group 4 is welded to the hollow lever 2 is 450 mm from the outermost end of the brake shoe hook 1 of the "F" shape structure, and the other end of the chain ring group 4 is welded to the hollow lever 2. The distance of the welding point 8 from the other end of the lever is 750mm. This distance is based on the best data obtained through trial and error in the weight of the brake shoe 10 and the operator's actual operation, which can save the operator the most effort.

Embodiment 3

[0076] The main technical solutions of the assembly and disassembly tool for locomotive brake shoes in this embodiment are the same as those in Embodiment 1. The features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0077] The hollow lever, adjustable wrench, hook body and brake shoe hook are made of stainless steel, such as aerospace square stainless steel welded pipe, the specification is 20mm×20mm×0.8mm, and the material is 304 stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com