Aerobic granular sludge treatment facility and method

A technology of aerobic granular sludge and treatment facilities, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, biological water/sewage treatment, etc., can solve the problem of low biomass of activated sludge and treatment efficiency Not high enough, not stable enough to operate, etc., to achieve the effects of rich biological populations, easy sediment removal, and improved water flow conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

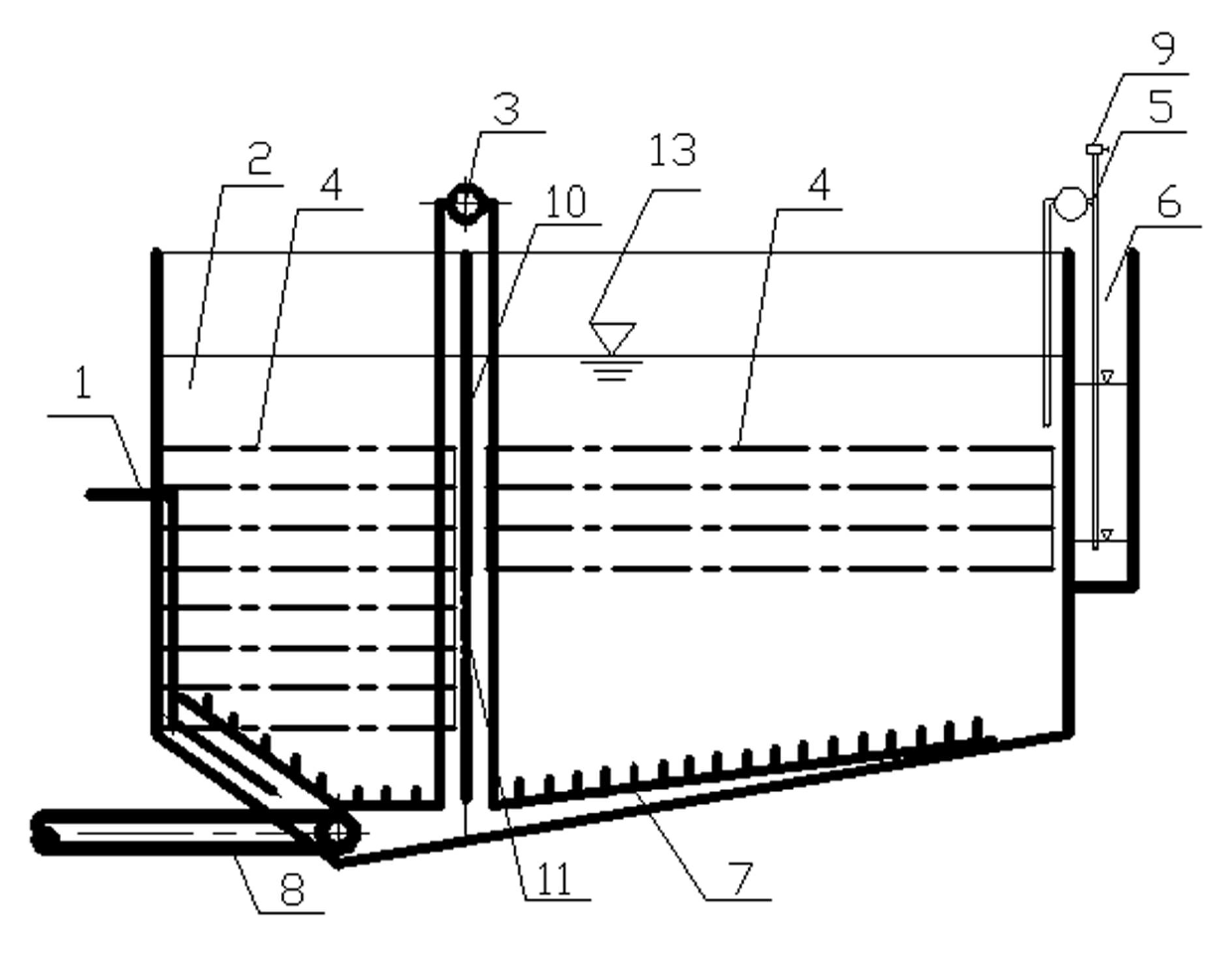

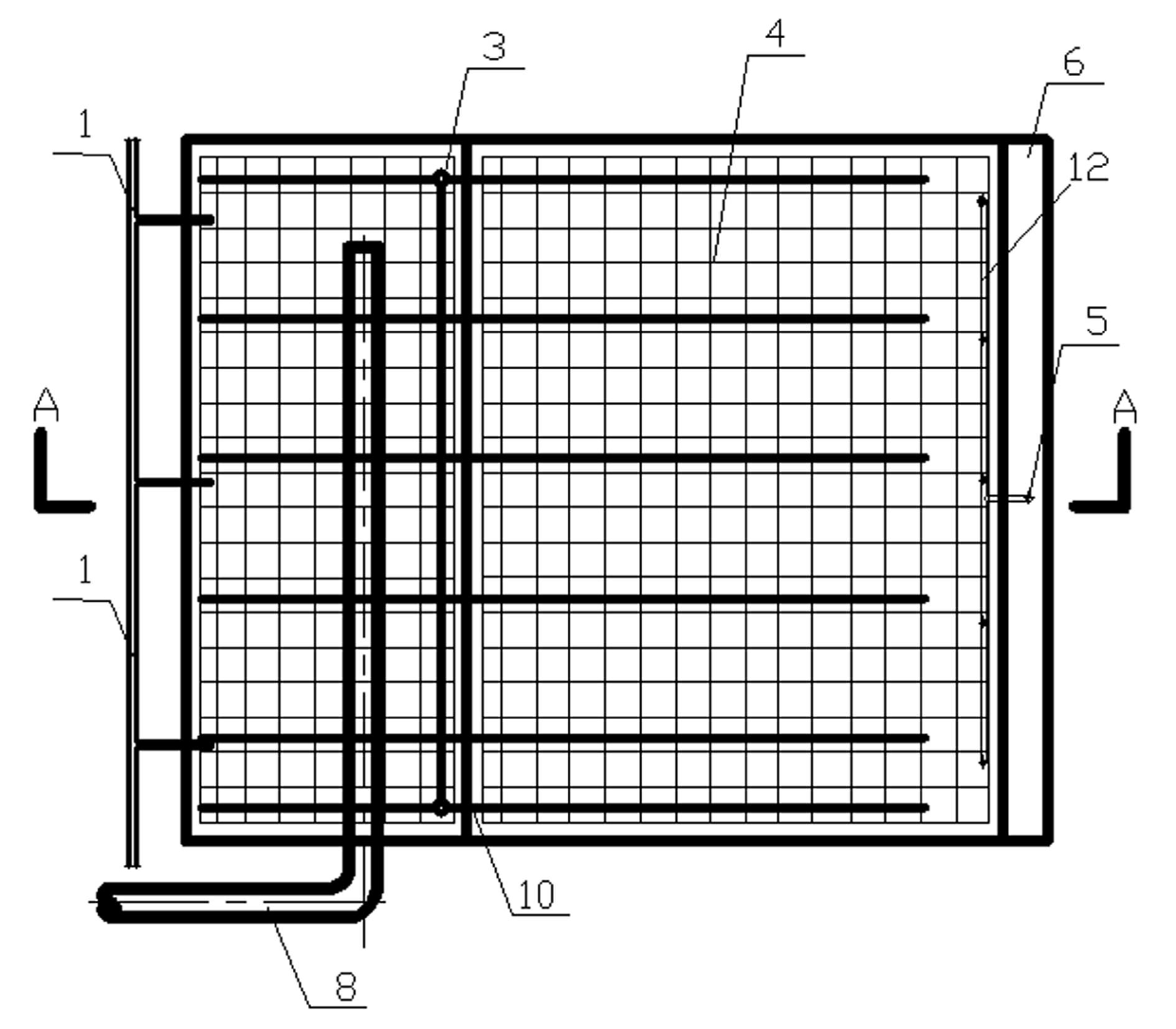

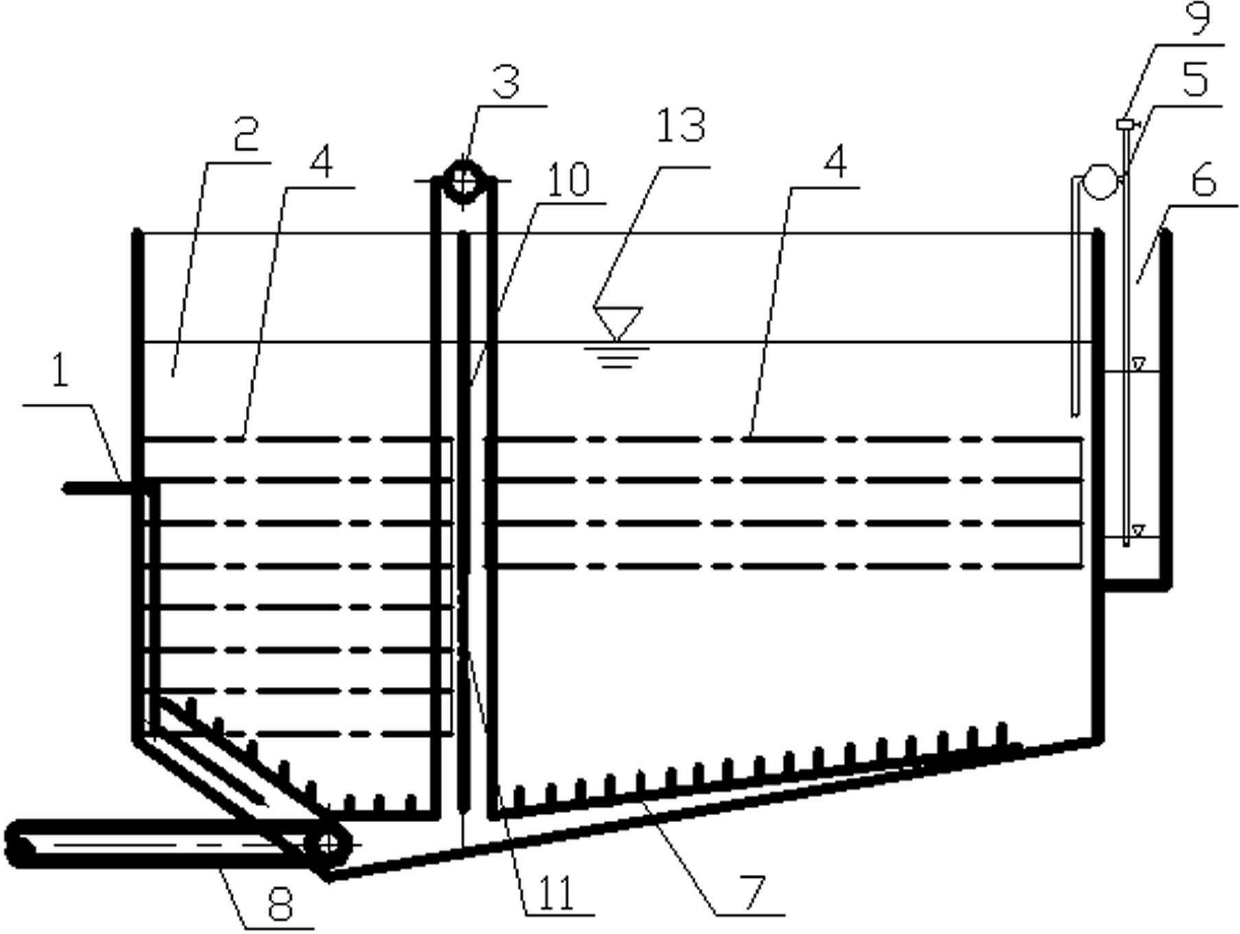

[0025] Examples of facilities such as figure 1 and figure 2 Shown: a kind of aerobic granular sludge treatment facility provided by the present invention comprises a rectangular reaction tank, a sewage inlet pipe 1, and a sewage discharge pipe 8; the rectangular pool is provided with a partition 10, which divides the rectangular reaction tank into water inlets Zone 2 and reaction zone 13 separate the water inlet area from the reaction pool for the purpose of strengthening biological breeding. The outlet of the sewage inlet pipe 1 is located at the bottom of the water inlet zone 2, and the water inlet zone 2 and the reaction zone 13 are respectively placed approximately There are several parallel frame screens 4, the frame screens 4 are roughly perpendicular to the partition 10, the partition 10 is provided with a large number of water inlet holes 11, and the bottoms of the water inlet 2 and the reaction zone 13 are equipped with aeration heads 7. The sewage pipe 8 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com