Solid catalyst component and catalyst for olefinic polymerization

A solid catalyst, a technology for olefin polymerization, which is applied in the field of olefin polymerization and can solve the problems of insufficient molecular weight distribution of polypropylene and poor processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

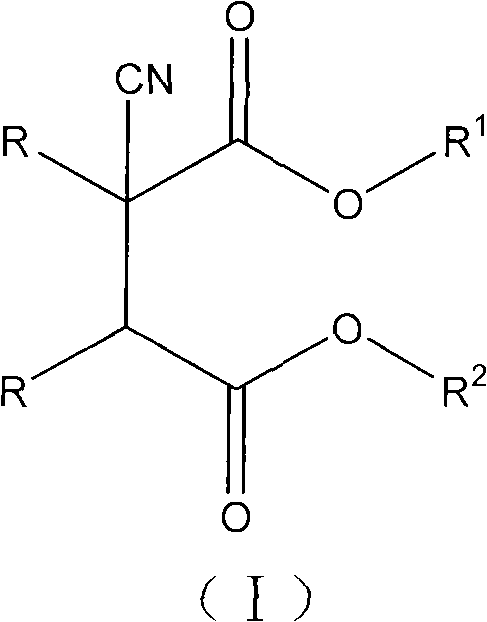

[0051] (1) Preparation of diethyl 2,3-diisopropyl-2-dicyanosuccinate (abbreviated as "JS" in Table 1): According to the implementation disclosed in International Patent Application No. PCT / CN2010 / 000202 In the method of Example 1, the amount of reactants and solvents in Example 1 was increased by 10 times, and 2,3-diisopropyl-2-dicyanosuccinate was purified by a chromatography column filled with silica gel. The crude ester was changed to vacuum distillation for separation and purification, and the 124-127°C fraction was collected under the pressure of 110-120 Pa. The infrared analysis of the product is consistent with the diethyl 2,3-diisopropyl-2-dicyanosuccinate obtained in Example 1 disclosed in PCT / CN2010 / 000202.

[0052] IR(cm -1 ): 2979, 2881, 2246, 1733, 1469, 1394, 1371, 1299.6, 1141. (2) Preparation of 2-isopropyl-2-(3-methylbutyl)-1,3-dimethoxypropane (referred to as "2#ether" in Table 1): According to Chinese Patent No. ZL91108297. 2 Prepared by the disclosed method....

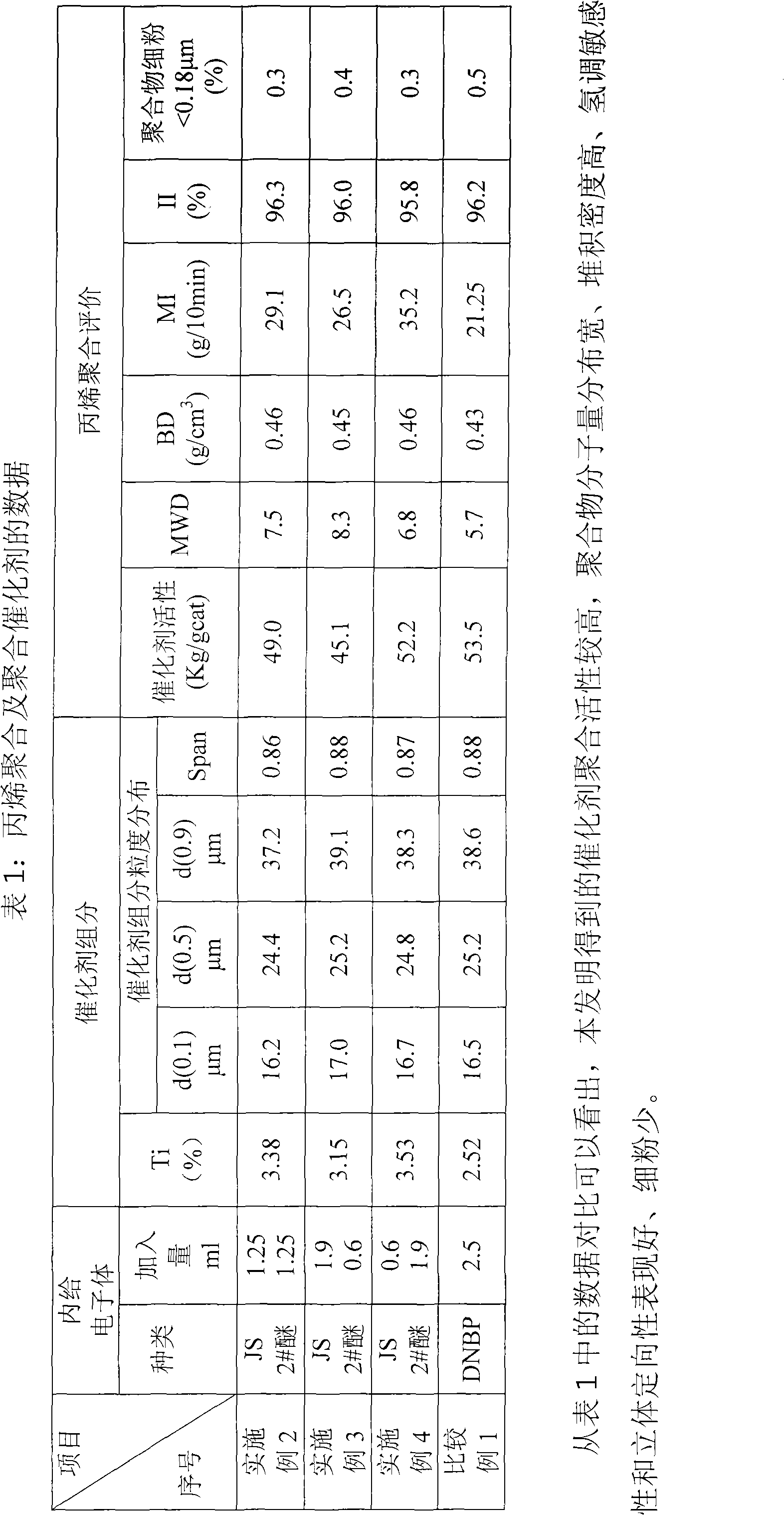

Embodiment 2

[0054] (1) Preparation of catalyst components

[0055] Select magnesium alkoxide (d(0.5) is 26.4μm, Span value is 0.85) 10g and toluene 50ml, 2,3-diisopropyl-2-dicyanosuccinate prepared by the method of Example 1 (Abbreviated as "JS" in Table 1) 1.25ml, 2-isopropyl-2-(3-methylbutyl)-1,3-dimethoxypropane (abbreviated as "2#ether" in Table 1 ) 1.25ml is prepared as a suspension; in a 300ml reaction kettle that has been repeatedly replaced by high-purity nitrogen, 10ml of toluene and 90ml of titanium tetrachloride are added, and the temperature is raised to 80°C, and then the prepared suspension is added to the kettle at a constant temperature of 1 After hours, continue to raise the temperature to 110°C, keep the temperature constant for 2 hours, and then filter the liquid clean. Then add a mixed solution of 120ml of toluene and 30ml of titanium tetrachloride and heat it up to 110°C and stir for 1 hour. After 3 times of treatment, the liquid is filtered off, and the solid obtained ...

Embodiment 3

[0060] Except in the preparation (1) of the catalyst component, the 2,3-diisopropyl-2-dicyanosuccinate obtained in Example 1 (abbreviated as "JS" in Table 1) and 2 -Isopropyl-2-(3-methylbutyl)-1,3-dimethoxypropane (referred to as "2#ether" in Table 1) was added in addition to 1.9ml and 0.6ml respectively , Others are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com