Phenolic resin compound for wet-curtain paper, preparation method of phenolic resin compound and preparation method of wet-curtain paper

A technology of phenolic resin and composition, which is applied in the direction of inorganic compound addition, papermaking, paper, etc., can solve the problems of wet curtain paper, such as large influence on water absorption and water retention performance of base paper, poor water absorption and water retention performance, and slow water absorption speed, etc. Achieve good water solubility, enhance water absorption and water retention, and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the phenolic resin composition for wet curtain paper, comprising:

[0032] Phenol and formaldehyde undergo polycondensation reaction under the action of a basic catalyst to obtain an intermediate product;

[0033] Adding a hydroxyl-containing water-soluble compound and / or a desiccant to the intermediate product, and continuing the reaction to obtain a phenolic resin composition.

[0034] In the invention, phenol and formaldehyde are firstly added with a basic catalyst to carry out polycondensation reaction, and then a water-soluble compound containing a hydroxyl group and / or a desiccant are added to continue the reaction to obtain a phenolic resin composition.

[0035] In the present invention, firstly, phenol and formaldehyde are mixed, and then a basic catalyst is added to carry out polycondensation reaction. In the present invention, the formaldehyde is preferably an aqueous formaldehyde solution, and the m...

Embodiment 1

[0068] Add 940g of phenol (10mol) and 2432g of formaldehyde solution with a mass concentration of 37% into the reactor for mixing, add 37.6g of a mass concentration of 96% sodium hydroxide solution, heat up to 80°C at a constant temperature, and continue to add 282g of glycerol for constant temperature reaction When the viscosity is 60-70cp / 25°C, quickly cool down to below 40°C to obtain a phenolic resin liquid;

[0069] Mix the phenolic resin solution and water evenly at a mass ratio of 1:3 to obtain a resin solution; immerse the base paper in the resin solution, dry the resin-impregnated paper at 60°C for 10 minutes, and continue drying at 130°C Drying at low temperature for 20 minutes, and then constant temperature and humidity for 3 hours at 25°C and 50% humidity to obtain wet curtain paper;

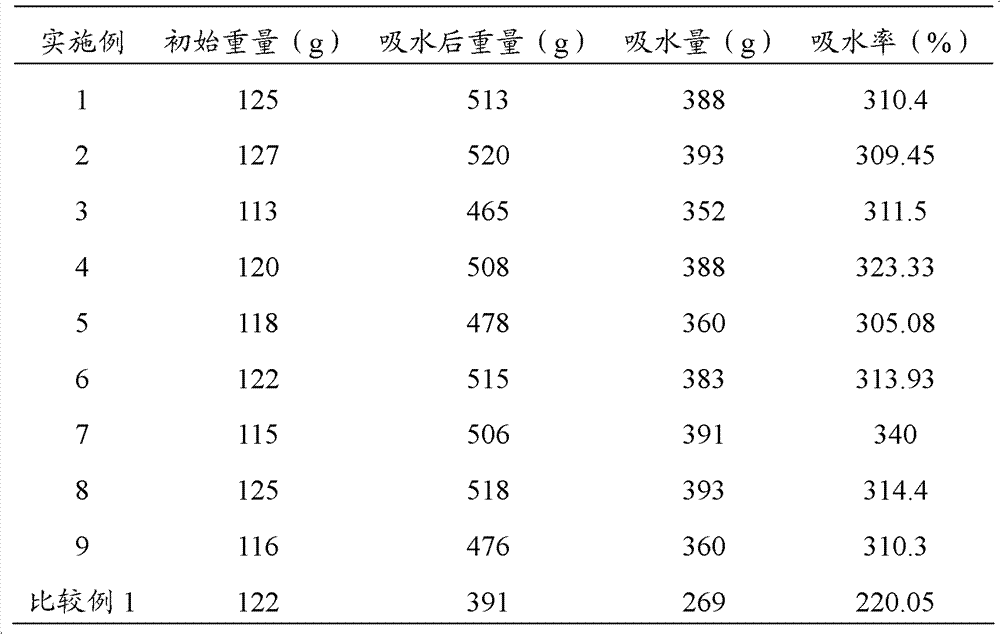

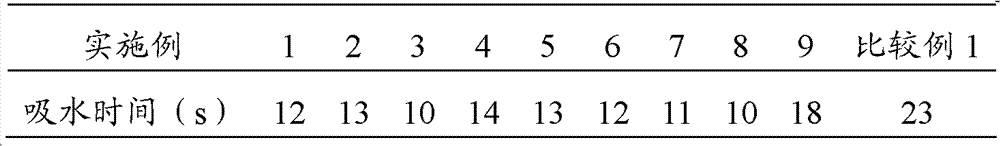

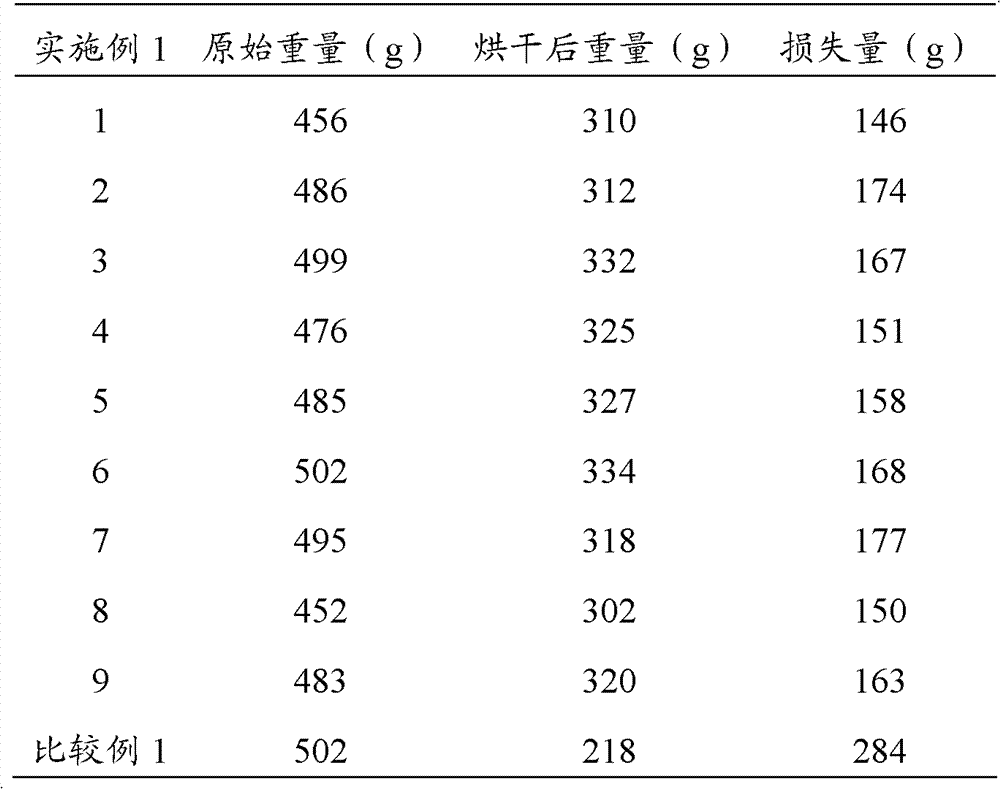

[0070] Measure the water absorption of the wet curtain paper according to the method described above, the results are shown in Table 1, and Table 1 is the water absorption test resul...

Embodiment 2

[0074] Add 940g of phenol (10mol) and 2432g of formaldehyde solution with a mass concentration of 37% into the reactor for mixing, add 37.6g of a mass concentration of 96% sodium hydroxide solution, heat up to a constant temperature of 80°C, and continue to add 141g of anhydrous calcium chloride React at a constant temperature until the viscosity is 60-70cp / 25°C, and quickly cool down to below 40°C to obtain a phenolic resin solution;

[0075] Mix the phenolic resin solution and water evenly at a mass ratio of 1:3 to obtain a resin solution; immerse the base paper in the resin solution, dry the resin-impregnated paper at 60°C for 10 minutes, and continue drying at 130°C Drying at low temperature for 20 minutes, and then constant temperature and humidity for 3 hours at 25°C and 50% humidity to obtain wet curtain paper;

[0076] Measure the water absorption of the wet curtain paper according to the method described above, the results are shown in Table 1, and Table 1 is the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com