Method for increasing yield of color value of capsanthin

A technology of capsanthin and capsicum, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problem of low color yield of capsanthin, achieve the effects of simple process, convenient operation, and shortened extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Taking the extraction of 1 ton of capsicum granules as an example, the method for improving the color yield of capsicum red pigment is described in detail.

[0019] (1) Add 10kg of soybean isoflavones (1% of the weight of pepper granules) to the extraction solvent, where the extraction solvent is a mixed solvent of 6# solvent oil and ethyl acetate, and the mixing ratio is 6# solvent oil:ethyl acetate=7 :3(weight);

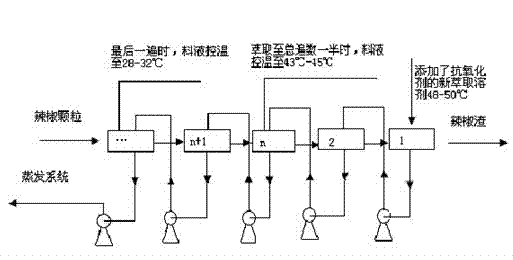

[0020] (2) Send the chili granules into continuous countercurrent extraction equipment, and conduct continuous countercurrent extraction between the chili granules and the extraction solvent added with soybean isoflavones, with a solid-to-liquid weight ratio of 1:3; the continuous countercurrent extraction equipment is as follows: figure 1 As shown; pepper particles are continuously fed from the head end of the equipment, while the extraction solvent is continuously fed from the tail end of the equipment, and the pepper particles and the extrac...

Embodiment 2

[0024] Embodiment 2: Taking the extraction of 1 ton of capsicum granules as an example, the method for improving the color yield of capsicum red pigment is described in detail.

[0025] (1) Add 10kg of vitamin E (1% of the weight of pepper granules) to the extraction solvent, where the extraction solvent is a mixed solvent of 6# solvent oil and acetone, and the mixing ratio is 6# solvent oil: acetone = 5:2 (weight );

[0026] (2) Send the pepper granules into the continuous countercurrent extraction equipment, and conduct continuous countercurrent extraction between the pepper granules and the extraction solvent added with vitamin E, and the weight ratio of solid to liquid is 1:4;

[0027] (3) During the extraction process, gradient cooling extraction was adopted, and the extraction was carried out 7 times. The temperature of the extraction solvent newly entering the continuous countercurrent extraction equipment was 50°C. Control the temperature of the feed liquid to 32°C, a...

Embodiment 3

[0030] Embodiment 3: Taking the extraction of 1 ton of capsicum granules as an example, the method for improving the color yield of capsicum red pigment is described in detail.

[0031] (1) Add 10kg of tea polyphenols (1% of the weight of pepper particles) to the extraction solvent, where the extraction solvent is a mixed solvent of 6# solvent oil and ether, and the mixing ratio is 6# solvent oil: ether = 6:2 (weight );

[0032] (2) Send the pepper granules into the continuous countercurrent extraction equipment, and conduct continuous countercurrent extraction between the pepper granules and the extraction solvent added with tea polyphenols, and the weight ratio of solid to liquid is 1:5;

[0033] (3) During the extraction process, gradient cooling extraction was adopted, and the extraction was carried out 7 times. The temperature of the extraction solvent newly entering the continuous countercurrent extraction equipment was 49 °C. Control the temperature of the feed liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com