Reinforced Rubber Tile with Laminated Top Layer and Air Cushion Effect

A rubber floor tile, enhanced technology, applied in the field of floor manufacturing system, can solve the problems of short life, easy wear of the floor, environmental hygiene problems, etc., to achieve the control of bacteria and dust, easy installation and maintenance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

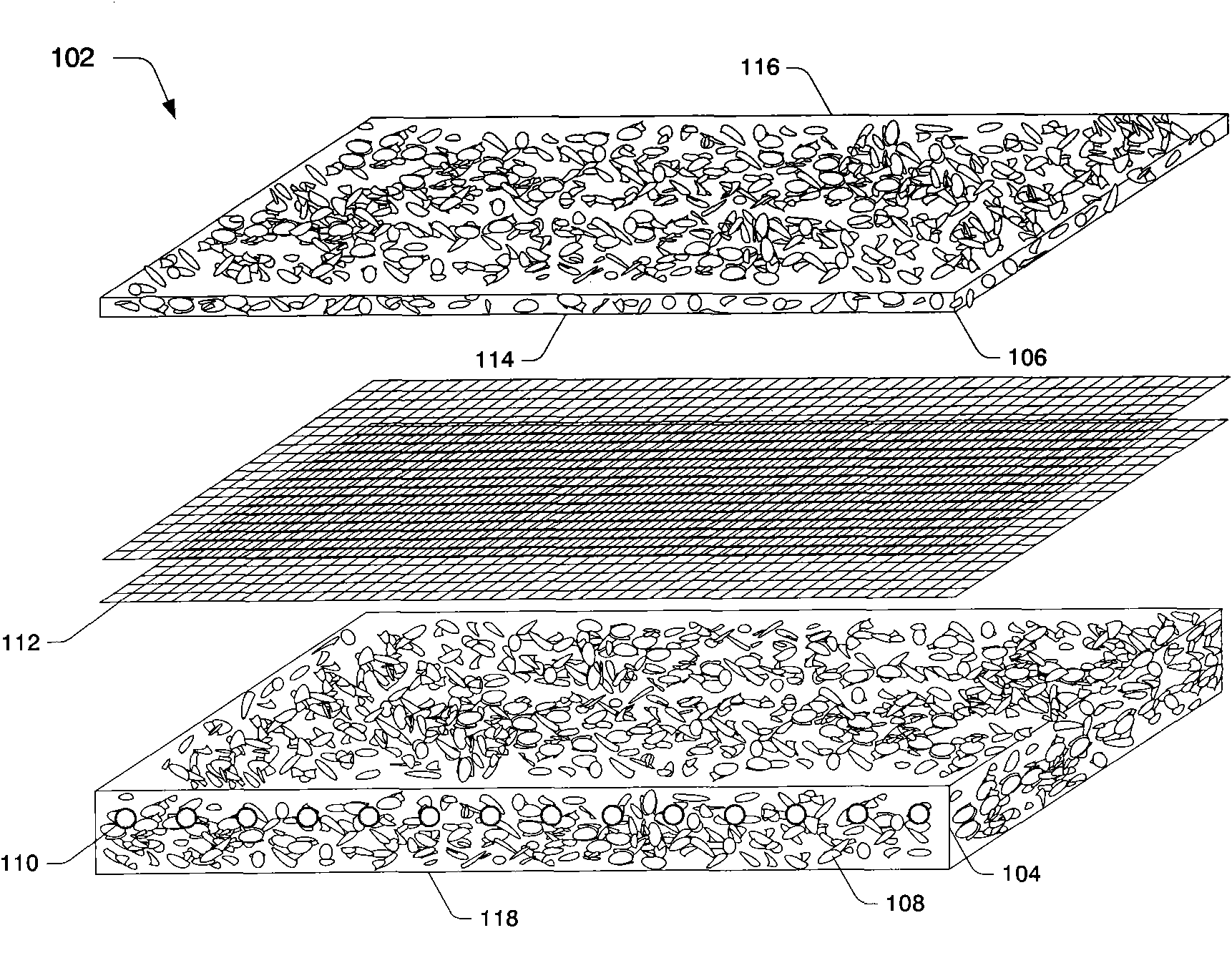

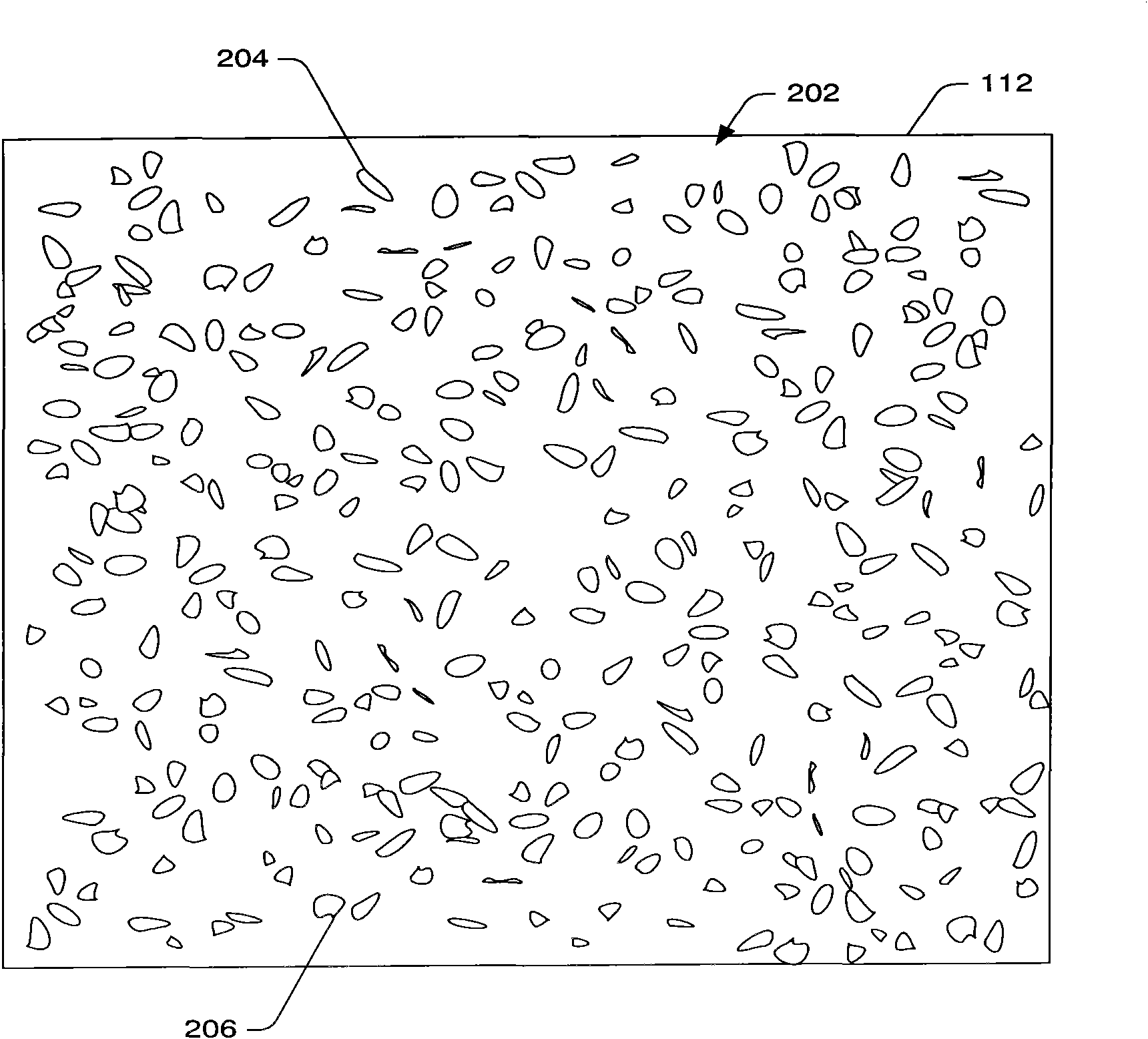

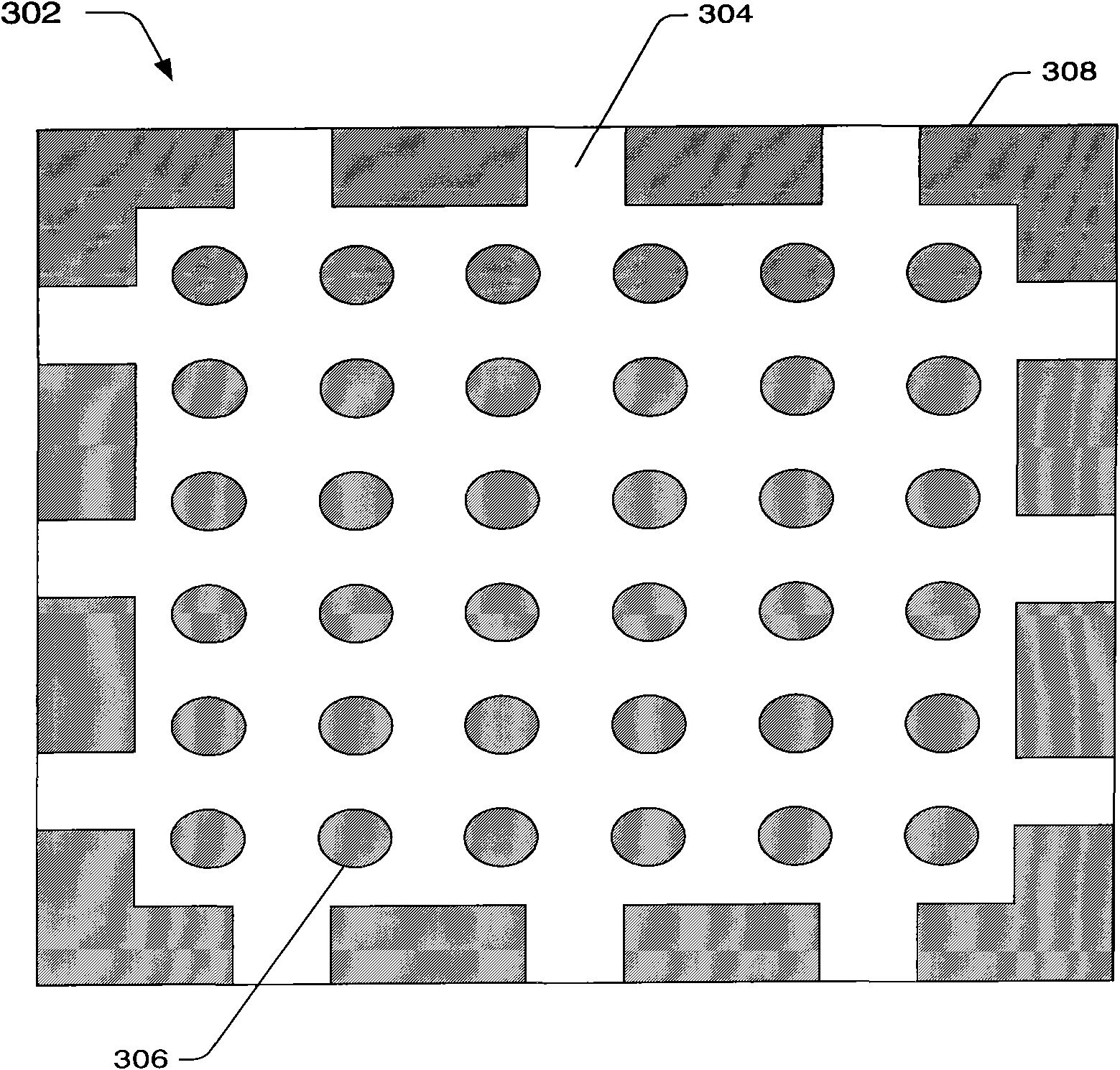

[0019] Embodiments of composite floor tiles having vibration-damping and anti-skid properties are detailed below. The composite floor tile has a facing layer composed of various materials, including elastic particles such as natural or synthetic rubber, polymers such as plastic, polyvinyl chloride (PVC), polyethylene (PE), polypropylene (PP), polyurethane synthetic Leather (PU synthetic leather), and / or plastic, and fibers such as carpet and / or other fabrics (eg: khaki). In certain embodiments, the surfacing layer is impermeable or substantially impermeable to dirt, dust, or other fine particles. The floor tile also has a shockproof bottom layer, which is made of elastic particles and reinforced by one or more mesh sheets, such as fiberglass mesh sheets, to provide support and stability for the composite floor tile in different environments. The density of the shockproof bottom layer can be lower than that of the facing layer. In at least one embodiment of the present applic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap