Guide mechanism for directing rotary steering drilling tool

A technology of rotary steerable drilling and steering mechanism, applied in directional drilling and other directions, can solve problems such as poor wellbore trajectory control accuracy, drilling limit depth limitation, poor wellbore cleaning, etc., and achieve good wellbore quality and flexible dynamic system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

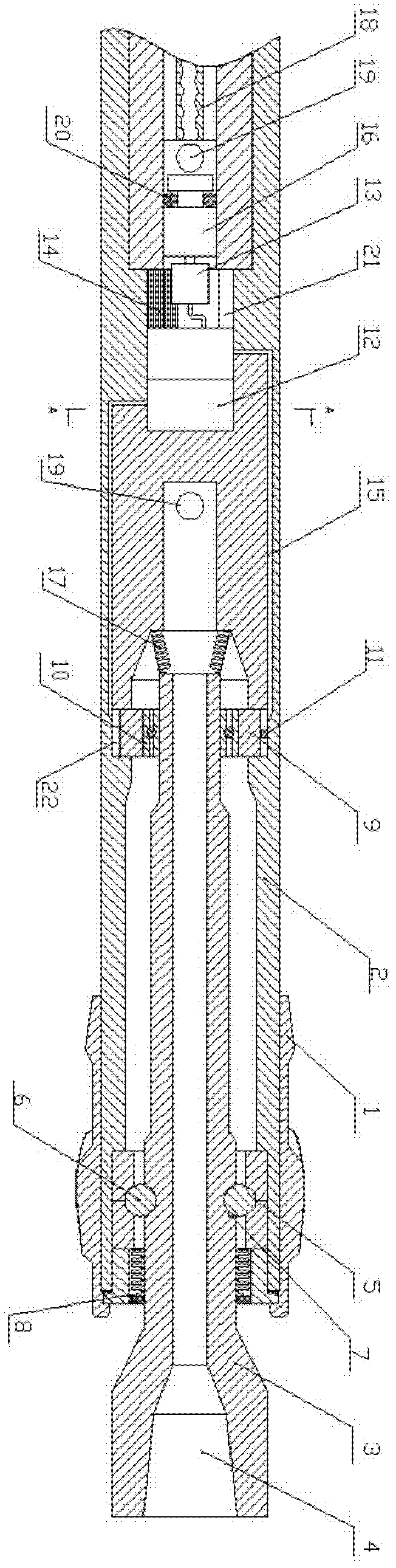

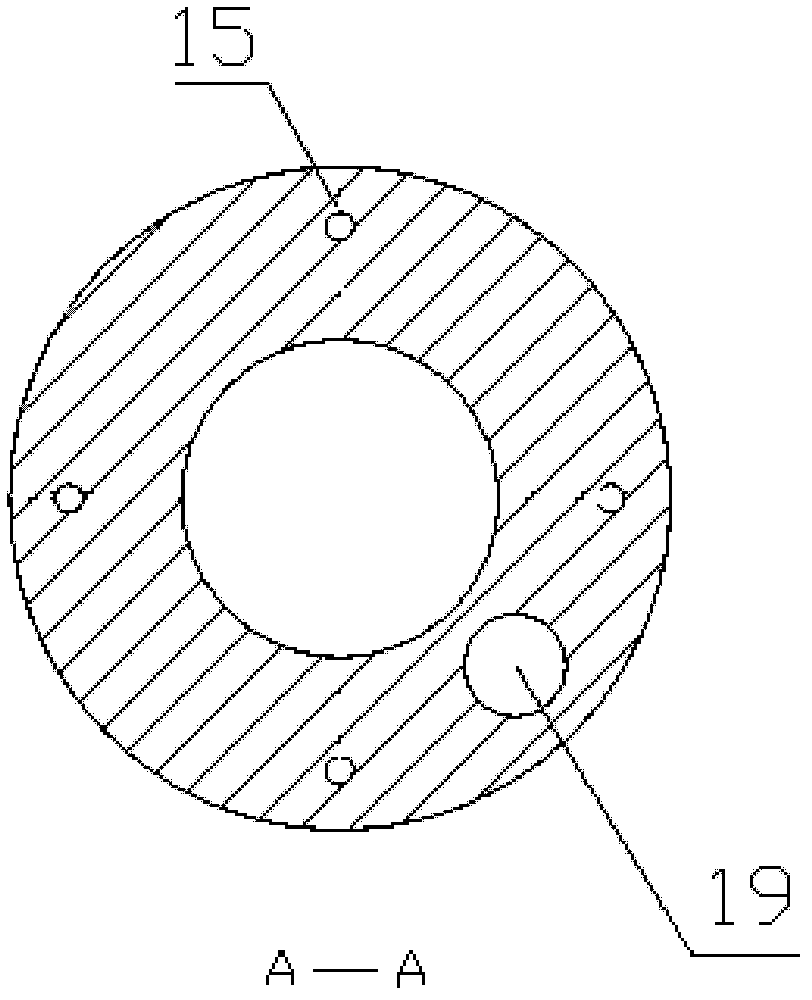

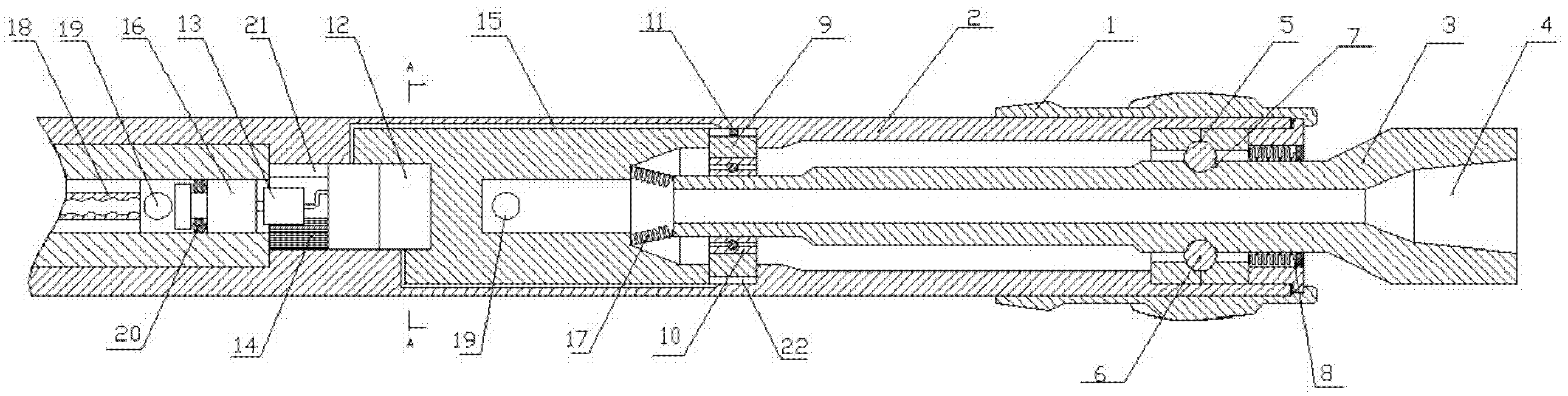

[0013] The present invention is described in detail below in conjunction with accompanying drawing.

[0014] refer to figure 1 , figure 2 , a guiding mechanism of a pointing rotary steerable drilling tool, comprising a near-bit stabilizer 1, the near-drill stabilizer 1 is fixed on the end of a rotating outer casing 2 through a screw connection, and a universal joint 5 is fixed inside the rotating outer casing 2, and the universal joint 5 is fixed in the rotating outer casing 2. The steel ball 6 in the section 5 is placed in the ball socket of the offset shaft 3, so that the offset shaft 3 and the rotating outer casing 2 rotate together, and the first sealing ring 8 is installed between the offset shaft 3 and the end of the outer casing 2 for use To prevent mud from entering the universal joint 5, the end of the offset shaft 3 is used to install the drill bit 4, and the upper end of the offset shaft 3 extends into the offset bearing 10, and is connected with the drilling flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com