Testing system of cutting force and torque loading reliability of numerical control turret power knife rest

A technology of dynamic tool rest and numerical control turret, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., to achieve high loading accuracy and real and credible test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

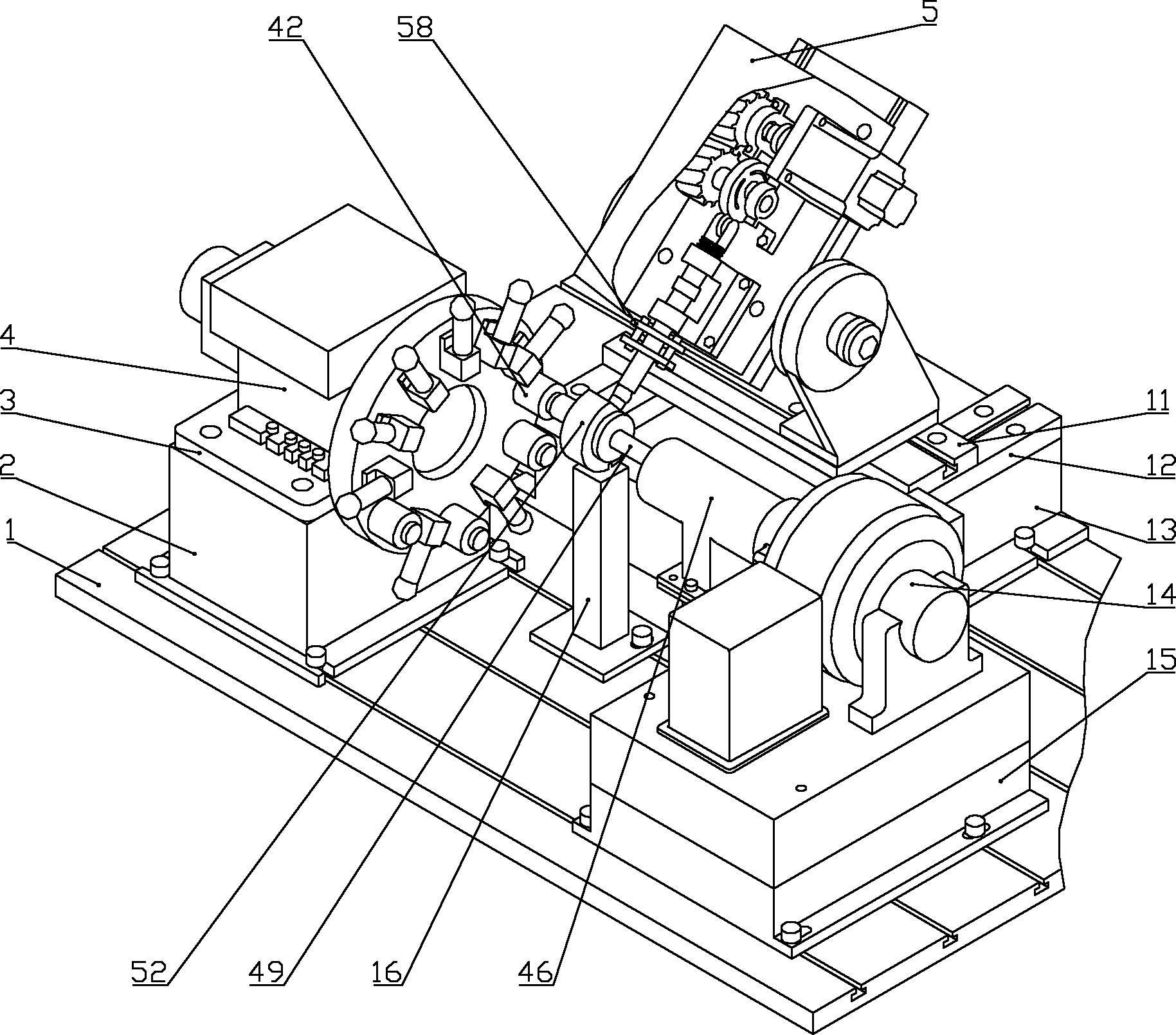

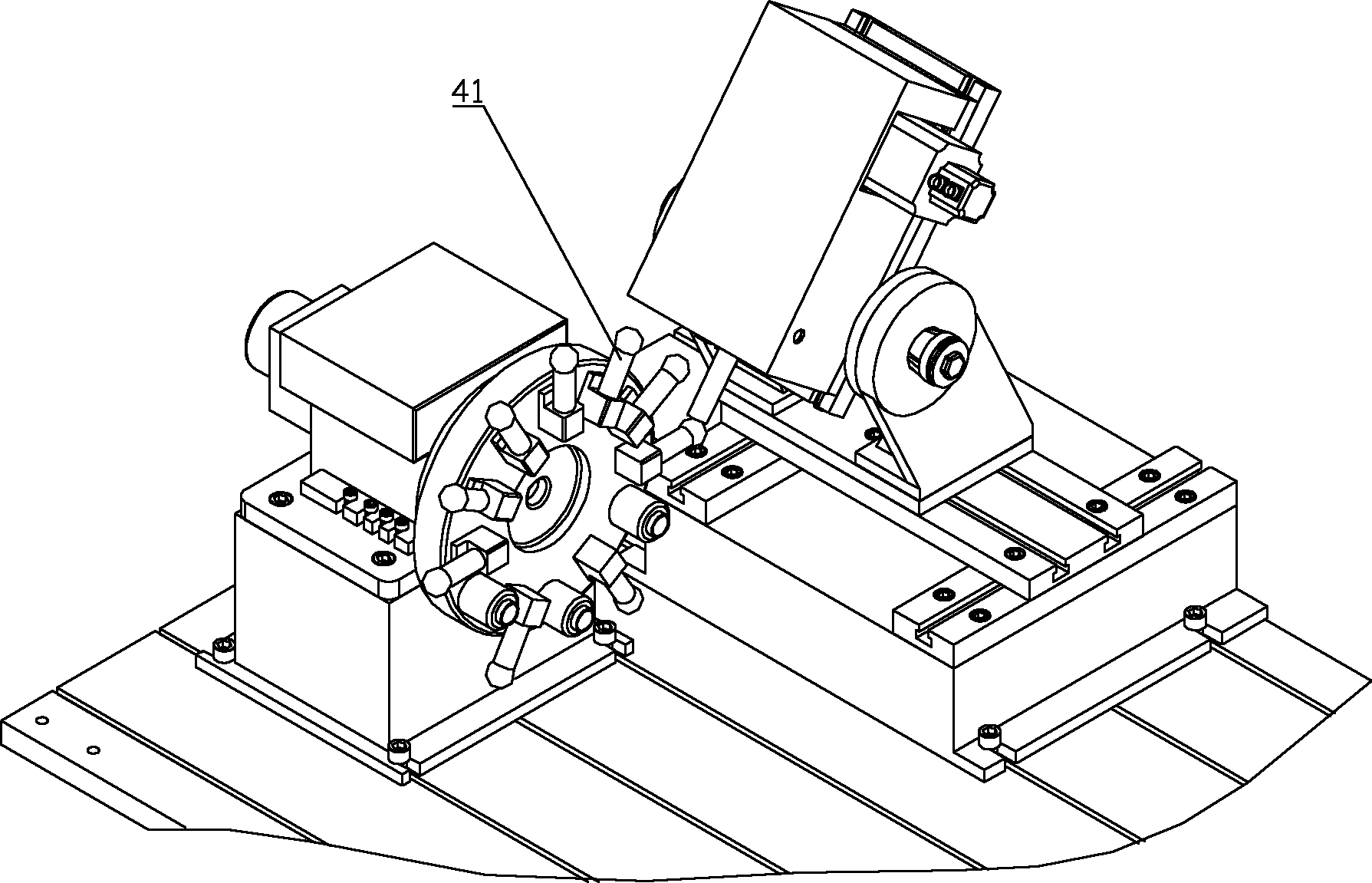

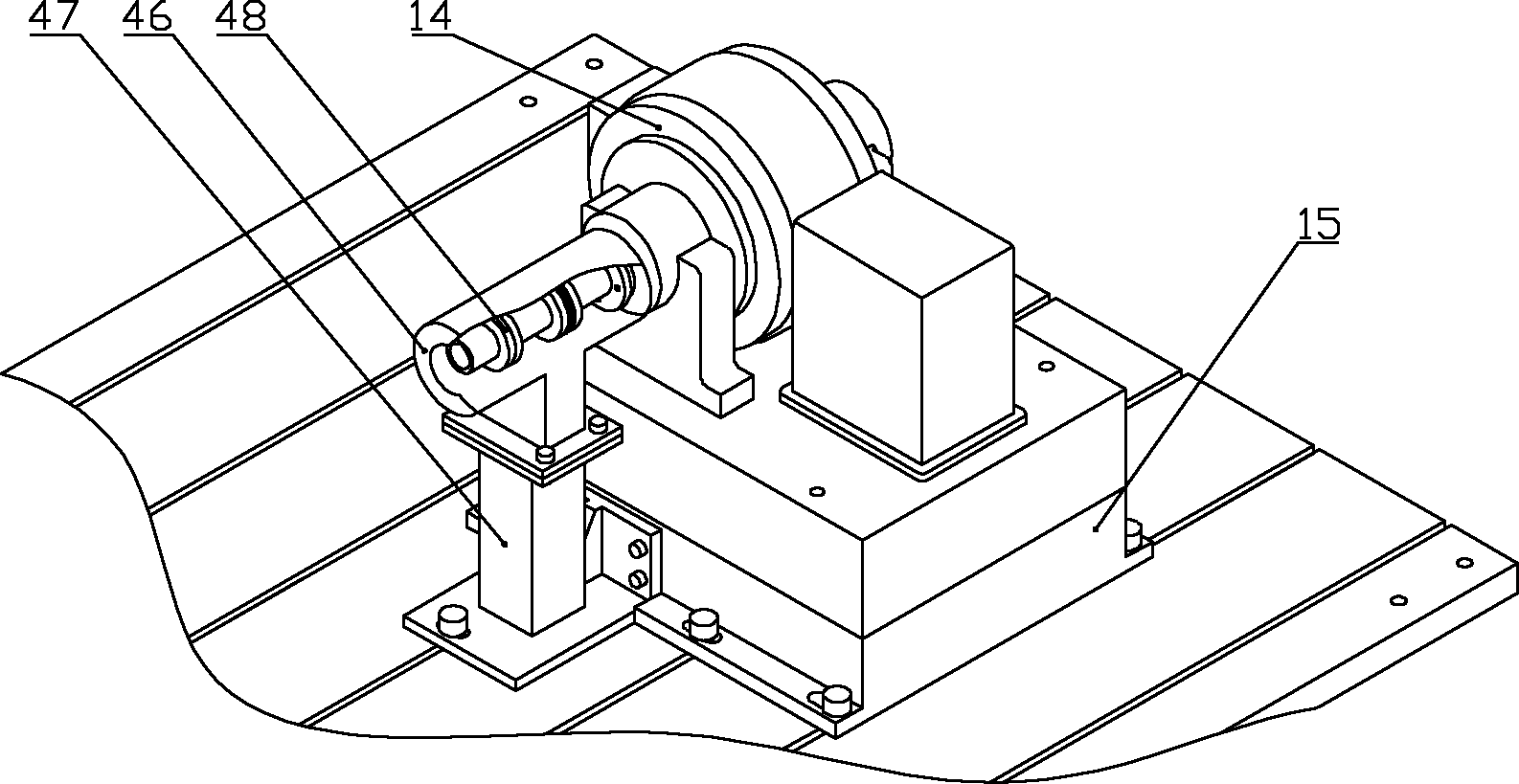

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

[0038] refer to figure 1 , The CNC turret power tool post cutting force and torque loading reliability test system of the present invention consists of a supporting part, a loading part and an automatic control system.

[0039] 1. Support part

[0040] The supporting part includes a numerical control turret power tool rest supporting part, a bearing loading unit supporting part, a cutting force loading supporting part and a torque loading supporting part.

[0041] 1. The supporting part of the CNC turret power tool post includes a No. 2 base 2 and a tool post backing plate 3. The No. 2 base 2 is a box-type structure, which is welded by six flat steel plates. The top surface and the bottom surface are parallel to each other. The four corners of the top plate are provided with threaded through holes for installing the knife holder backing plate 3. The bottom plate There are U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com