Micro-pipe internal flaw and appearance measurement device and method

A shape measurement and pipeline technology, applied in the direction of measuring devices, using optical devices, optical testing of defects/defects, etc., can solve the problem of not being able to quantitatively give the size and specific position of defects, and not satisfying the requirements of flexibility, automation, rapid detection, and fine Problems such as low precision of pipe or hole wall, to achieve the effect of fast measurement speed, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

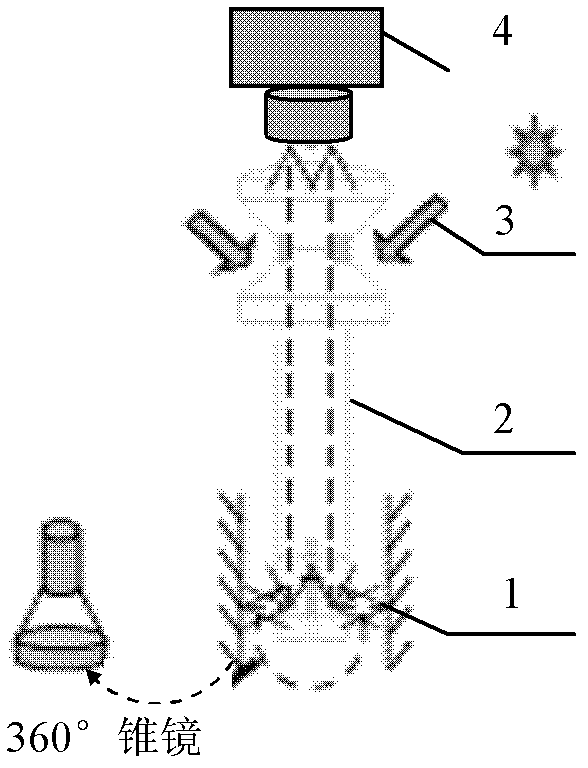

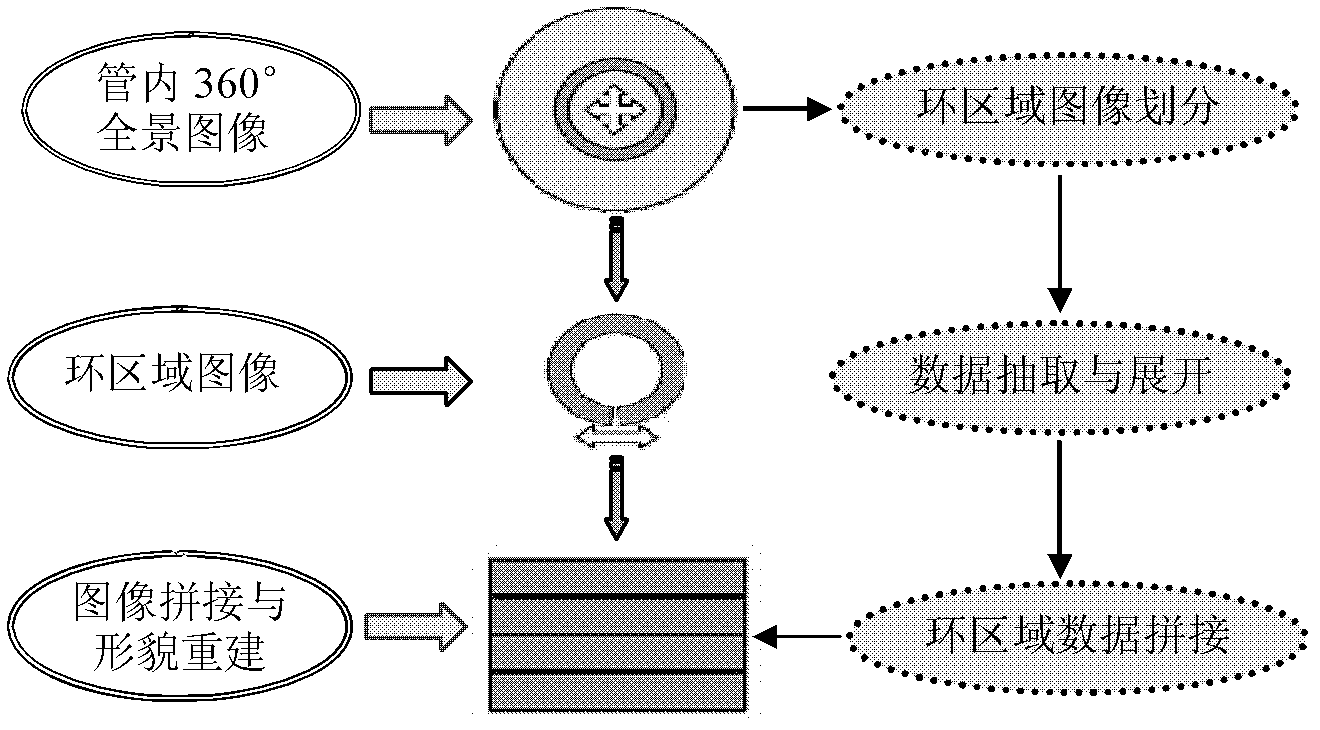

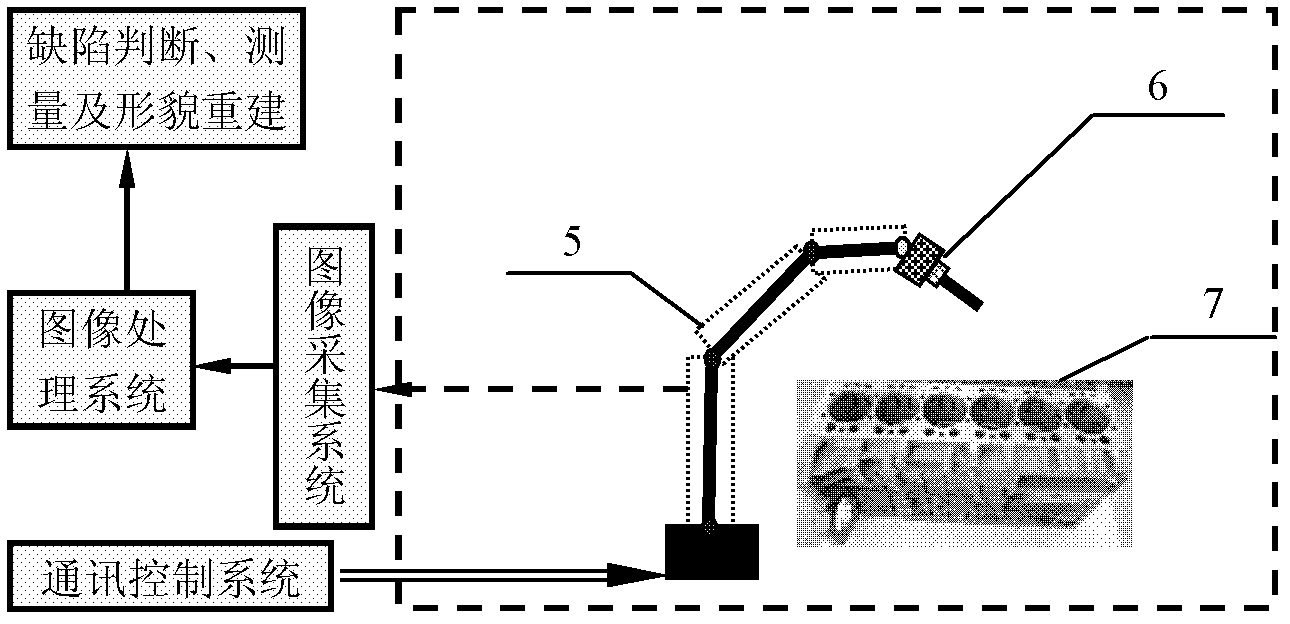

[0023] The technical solution adopted in the present invention is to break through the traditional mode of built-in sensors in the existing pipeline defect and shape measurement methods, propose a new idea of external light source introduction and internal image export, and place the illumination light source and image acquisition device outside the pipeline to be tested , the external illumination light is introduced into the area to be measured in the tube through the optical transmission component, and the optical image of the area to be measured is exported by the same optical transmission component, combined with image information processing technology to realize non-contact and automatic measurement of defects and shapes in the micro-pipe tube ; On this basis, introduce industrial robot technology into the application field of precision measurement of micro-pipes, and provide a motion control and support platform for the realization of flexible, fast, online defect and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com