Detecting method of specific capacity of negative electrode material of lithium ion battery after circulation

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problem that the specific capacity of negative electrode materials is difficult to accurately detect, and achieve the effect of low environmental requirements and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: hydrochloric acid cleaning recovery diaphragm

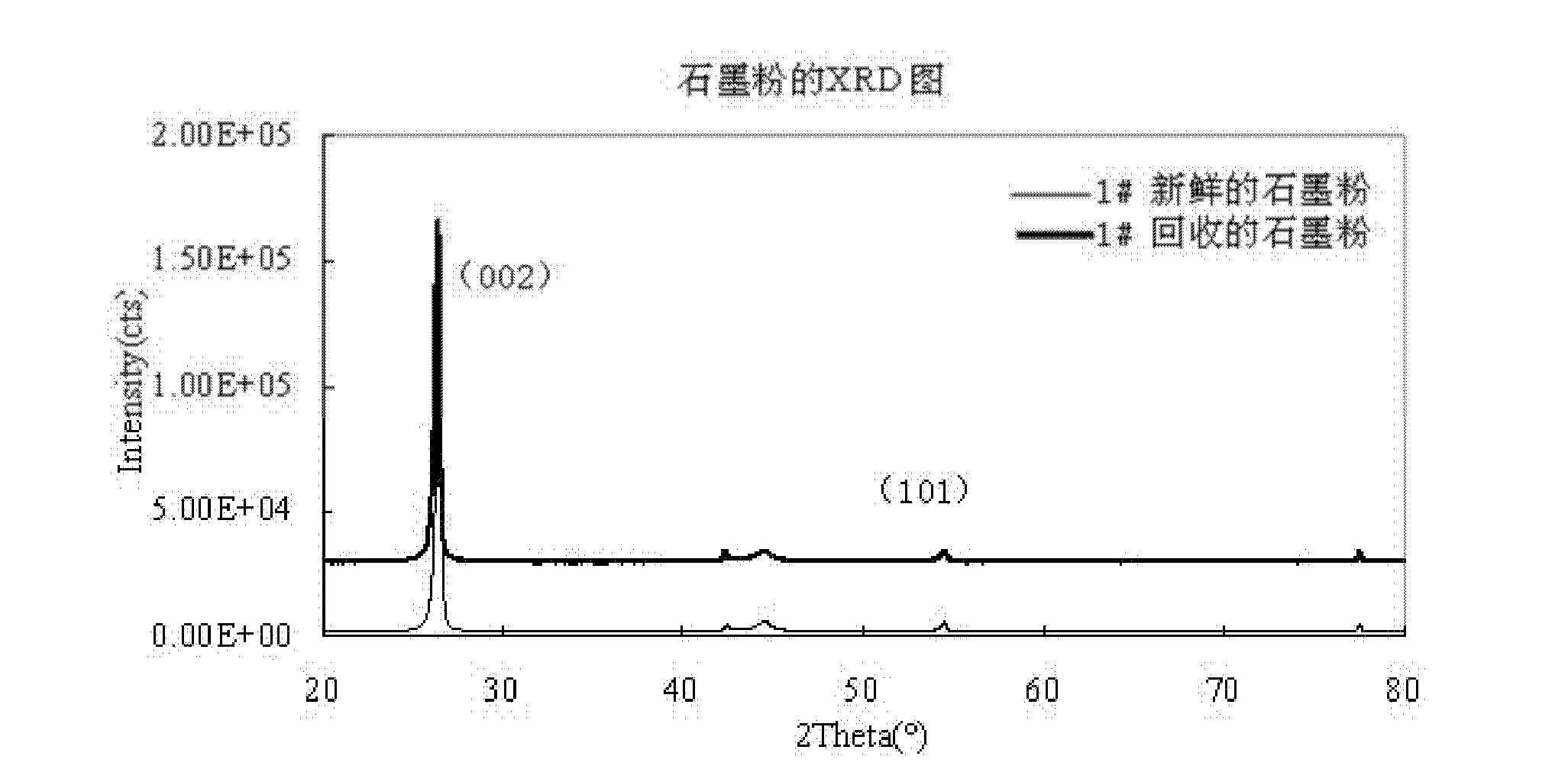

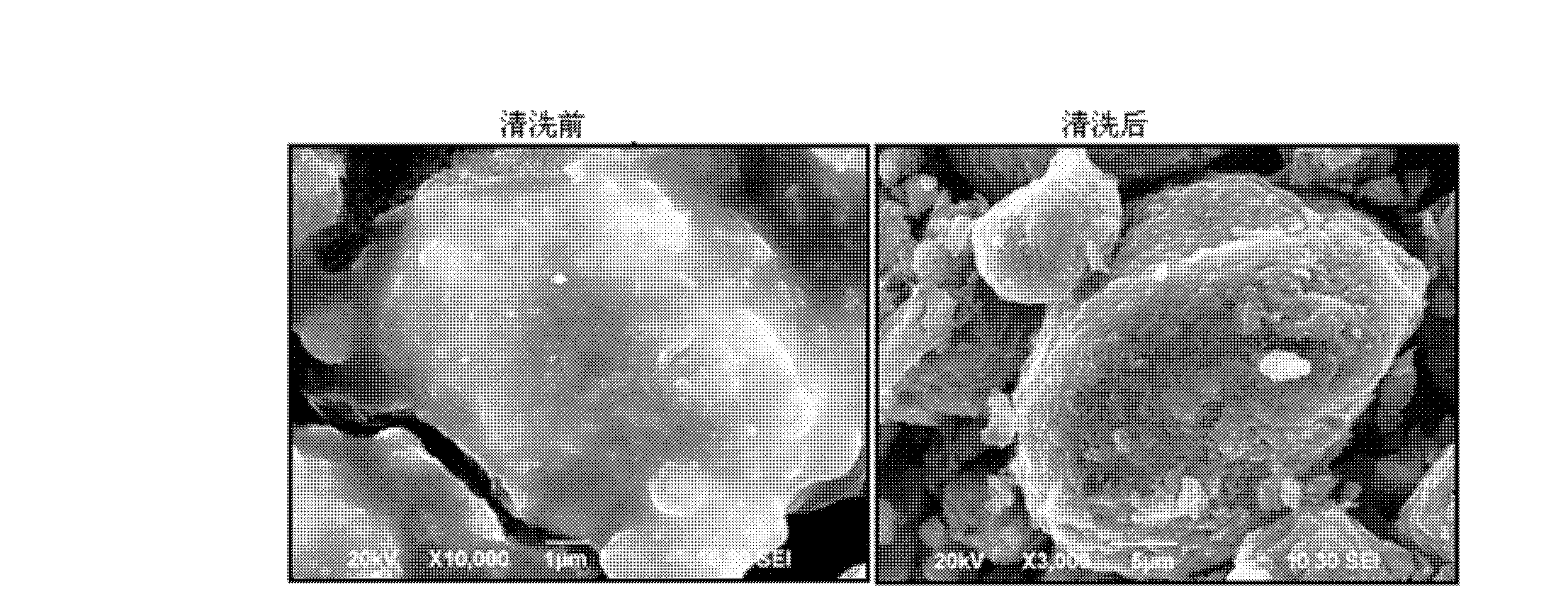

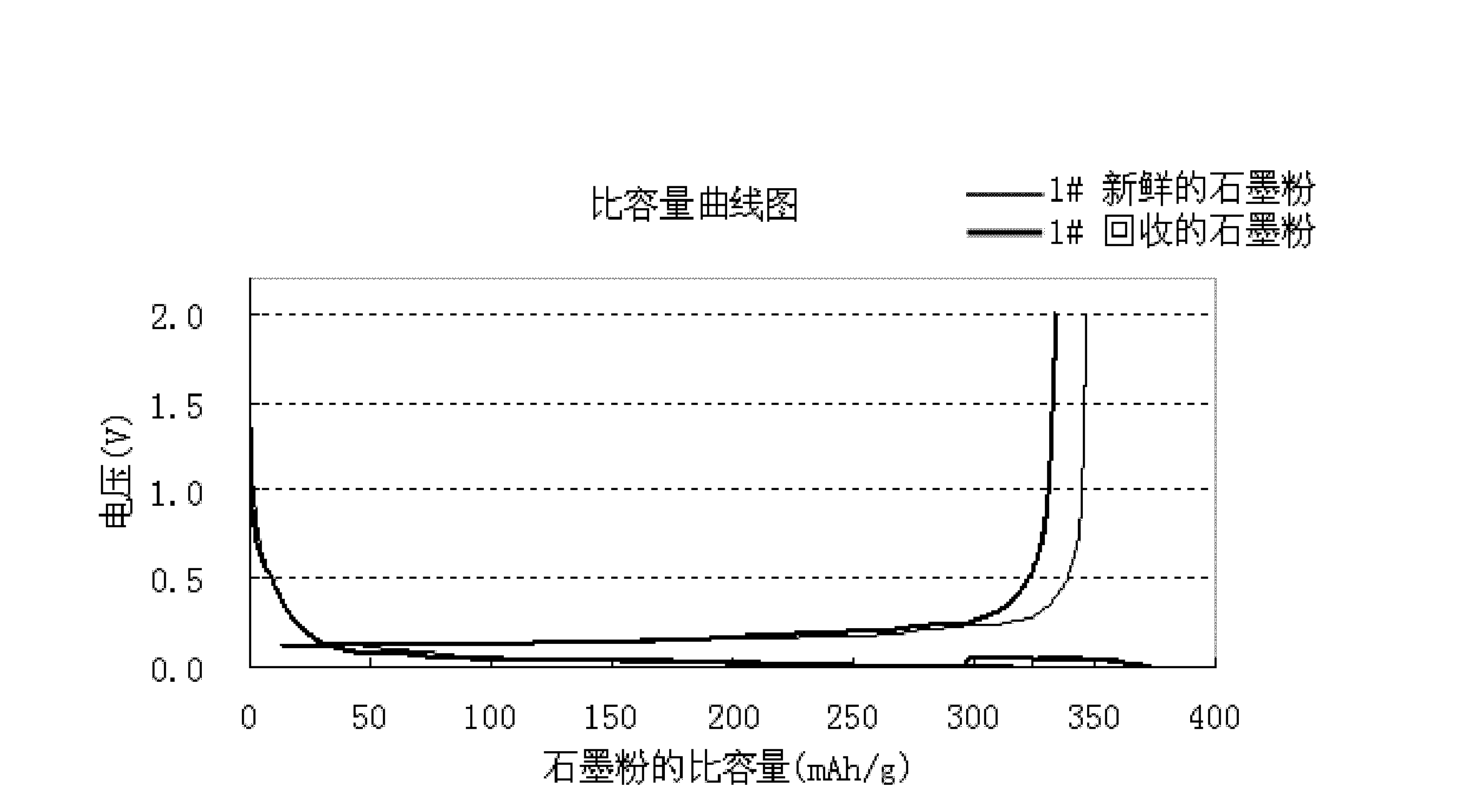

[0031]Use 1# graphite as the negative electrode material, discharge the 18650 lithium-ion battery at 0.1C to 1.5V after 1 cycle, disassemble the battery and take out the negative electrode; soak the electrode in DMC solvent for 30 minutes, shake to remove the negative electrode Lithium salt; after taking it out, dry the pole piece at 85°C; soak the pole piece with 5% hydrochloric acid by mass for about 30 minutes, and ultrasonically vibrate to make the diaphragm of the active material fall off from the current collector; Separation of solids and liquids from the acidic solution of the tablets, and washing the obtained solids with deionized water until the filtrate was neutral pH=7.0; after the separated solids were vacuum-dried at 85°C and ground, the obtained powders were subjected to 200-mesh Sieve to obtain graphite powder; mix graphite powder with conductive carbon, binder SBR and thickener CMC in a ratio...

Embodiment 2

[0032] Embodiment 2 Sulfuric acid cleans and recovers the diaphragm

[0033] Use 1# graphite as the negative electrode material, discharge the 18650 lithium-ion battery at 0.1C to 1.5V after 1 cycle, disassemble the battery and take out the negative electrode; soak the electrode in DMC solvent for 30 minutes, shake to remove the negative electrode Lithium salt; after taking it out, dry the pole piece at 85°C; soak the pole piece with 8% mass ratio of sulfuric acid for about 30 minutes, and ultrasonically vibrate to make the diaphragm of the active material fall off from the current collector; Separation of solids and liquids from the acidic solution of the tablets, and washing the obtained solids with deionized water until the filtrate was neutral pH=7.0; vacuum-dried the separated solids at 95°C and ground them, then subjected the obtained powders to 200-mesh Sieve to obtain graphite powder; mix graphite powder with conductive carbon, binder SBR and thickener CMC in a ratio o...

Embodiment 3

[0035] Discharge the 18650 lithium-ion battery with 1# graphite as the negative electrode material at 0.1C to 1.5V after 600 cycles, disassemble the battery and take out the negative electrode sheet; soak the electrode sheet in DMC solvent for 30 minutes, shake to remove the Lithium salt; after taking it out, dry the pole piece at 85°C; soak the pole piece with 5% hydrochloric acid solution by mass for about 30 minutes, and ultrasonically vibrate to make the diaphragm of the active material fall off from the current collector; The acidic solution of the diaphragm is subjected to solid-liquid separation, and the obtained solid is washed with deionized water until the filtrate is neutral pH=7.0; after the separated solid is vacuum-dried at 100°C and ground, the obtained powder is subjected to 200 Mesh sieving to obtain graphite powder; graphite powder and conductive carbon, binder SBR and thickener CMC are mixed in a ratio of 95:1:3:1, stirred and coated on copper foil, dried to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com