High-power-density onboard variable voltage rectifier

A technology of transformer rectifier and high power density, applied in the field of transformer rectifier, can solve the problems of low efficiency, large weight, large transformer volume, etc., and achieve the effects of good safety, light weight and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

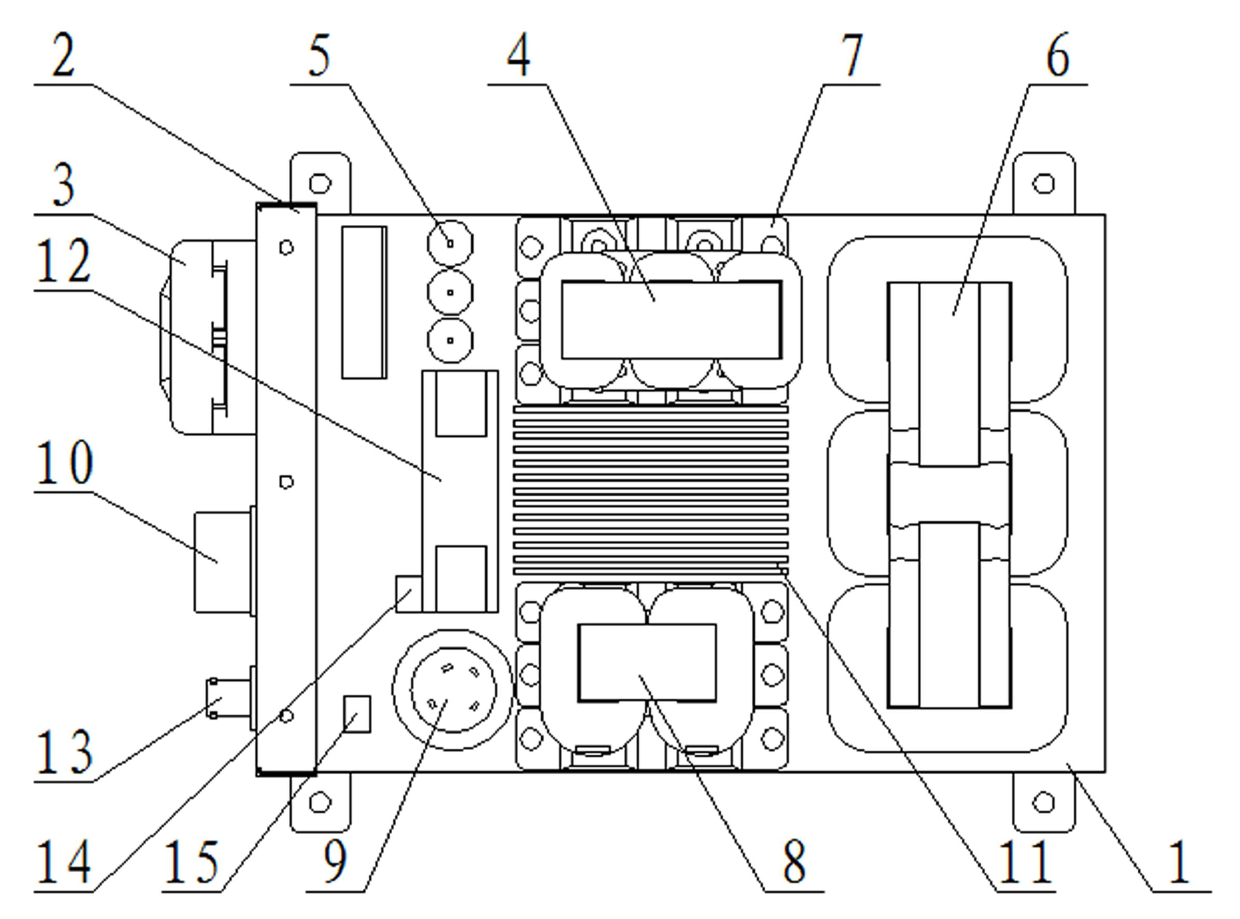

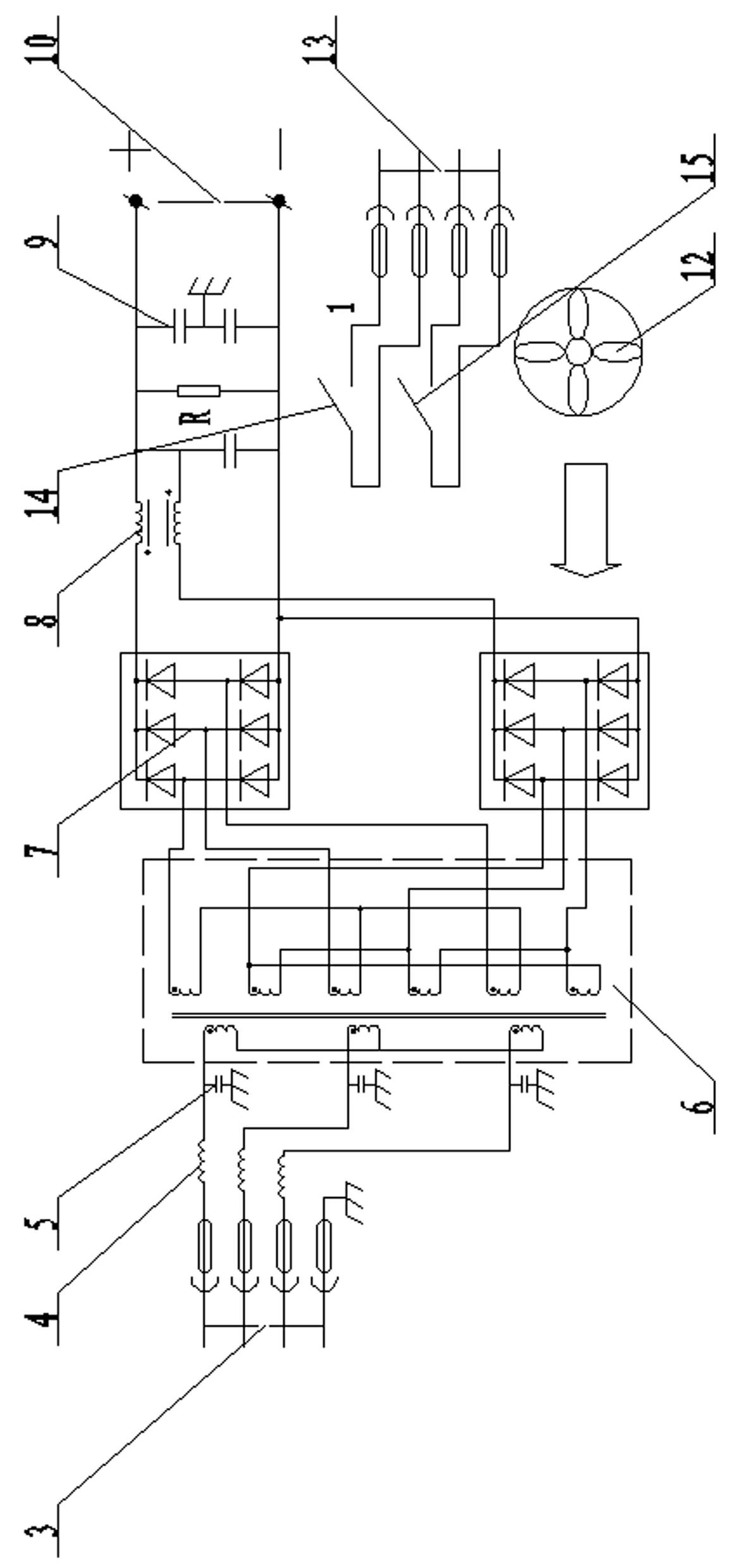

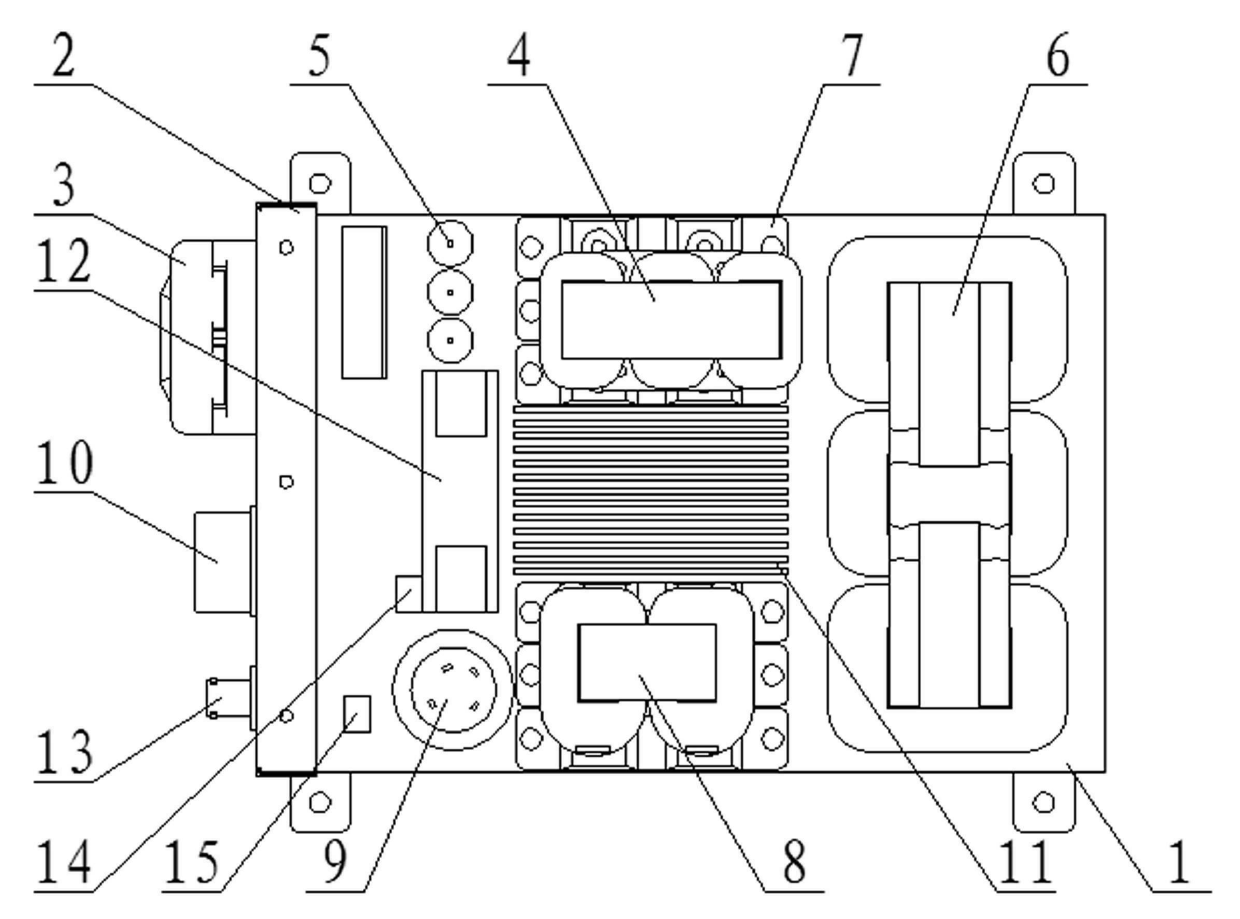

[0024] figure 1 As shown, a high power density airborne transformer rectifier includes a base plate 1, a panel 2, an input connector 3, a reactor 4, an input filter capacitor 5, a pulse transformer 6, a double diode 7, a flat reactor 8, and an output filter capacitor 9. Output connector 10, radiator 11, fan 12, alarm connector 13, fan failure alarm switch 14 and temperature alarm switch 15. The panel 2 is arranged on one side of the base plate 1, and the input connector 3, the output connector 10 and the alarm connector 13 are provided on the panel 2, and the pulse transformer 6 is provided on the base plate 1 on the other side of the base plate, and the pulse transformer 6 and the panel 2 The base plate between is provided with a radiator 11 composed of a number of inserts that are crimped on the base plate at intervals. The base plate 1 on any two opposite sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com