Photovoltaic array combiner box

A photovoltaic array and combiner box technology, applied in the field of photovoltaic power generation, can solve the problems that the output power of the input branch cannot reach the maximum, the maximum power point is different, etc., to simplify the thermal structure design and device selection, reduce heat loss, and improve The effect of overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

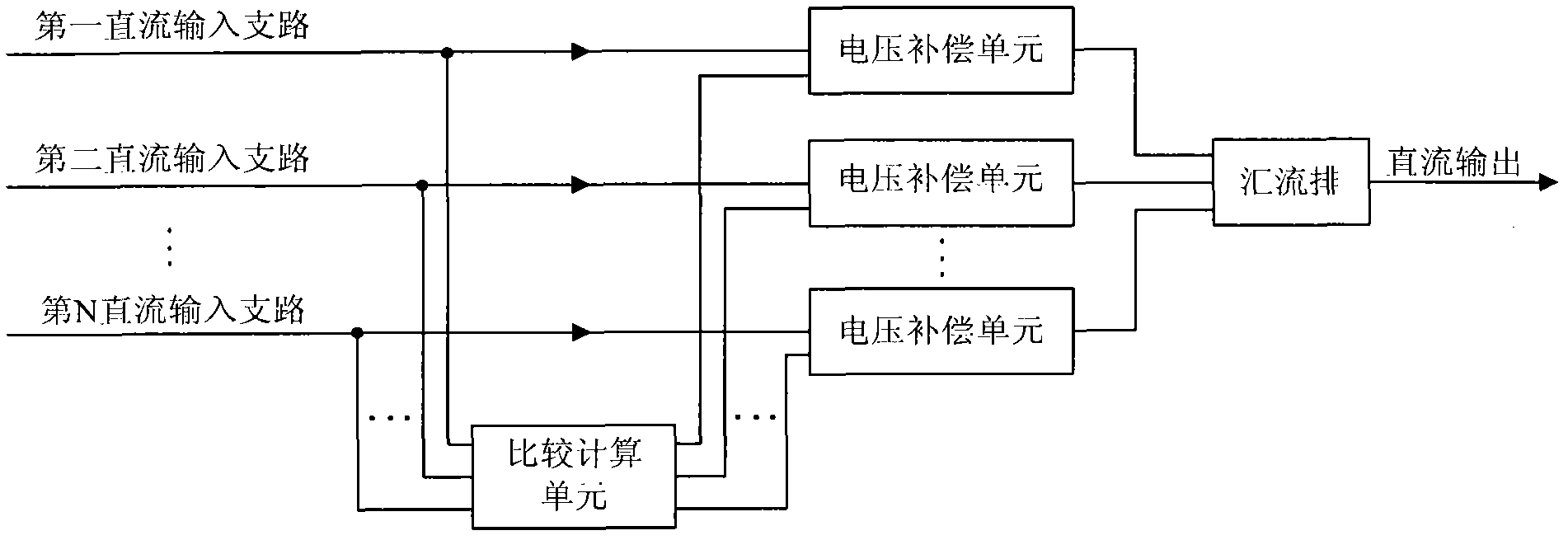

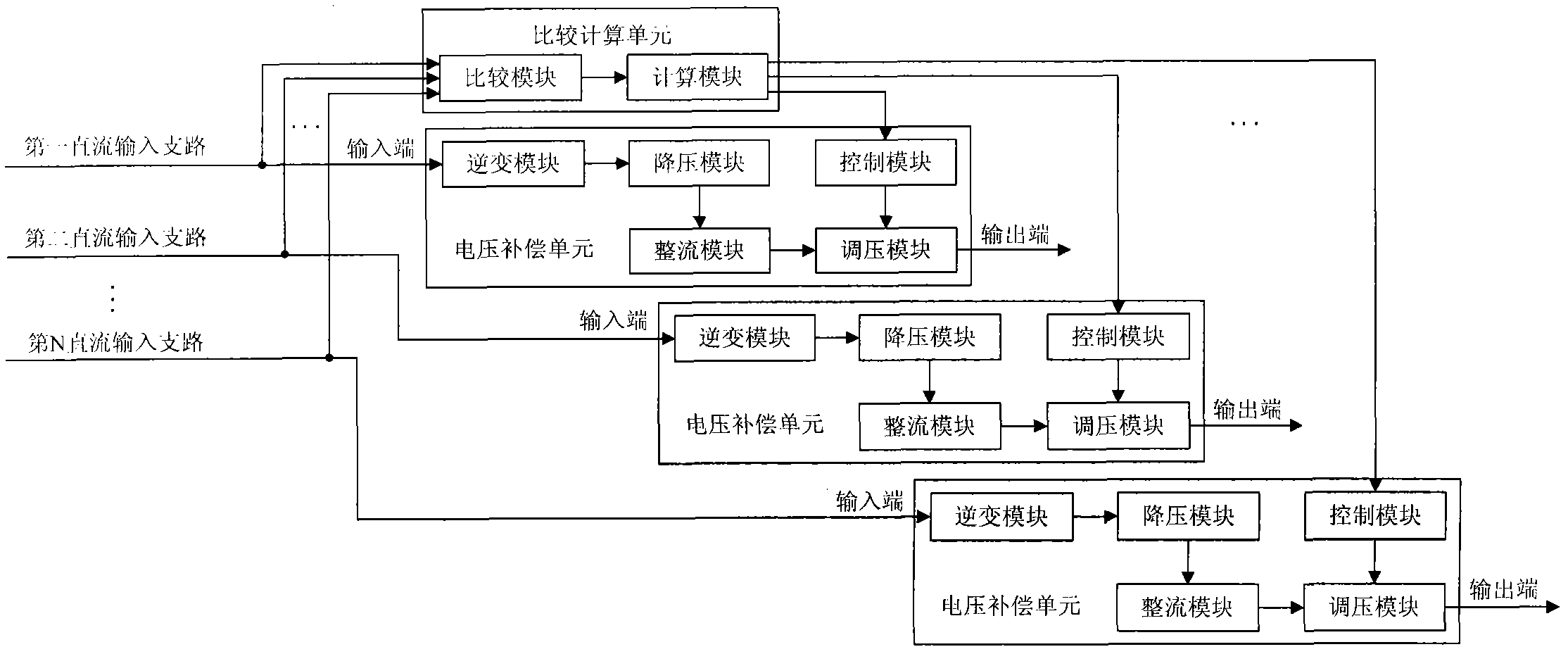

[0041] Such as figure 1 As shown, the photovoltaic array combiner box includes multiple DC input branches, multiple voltage compensation units, and a comparison calculation unit. Wherein, each DC input branch has a maximum power tracking function. Here, the maximum power tracking function of the DC input branch can be achieved by adding DC / DC boost modules to the input branches of the photovoltaic array combiner box respectively. Of course, other methods that can realize maximum power tracking can also be used. Functional modules are implemented.

[0042] The multiple DC input branches are connected in parallel and then converged into one DC output. A bus bar can be used to connect the multiple DC input branches in parallel and then converged into one. Preferably, the bus bar is a copper bus bar. The positive and negative poles of the input end of each DC input branch are respectively connected to the positive and negative poles of the output end of a photovoltaic array (sol...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

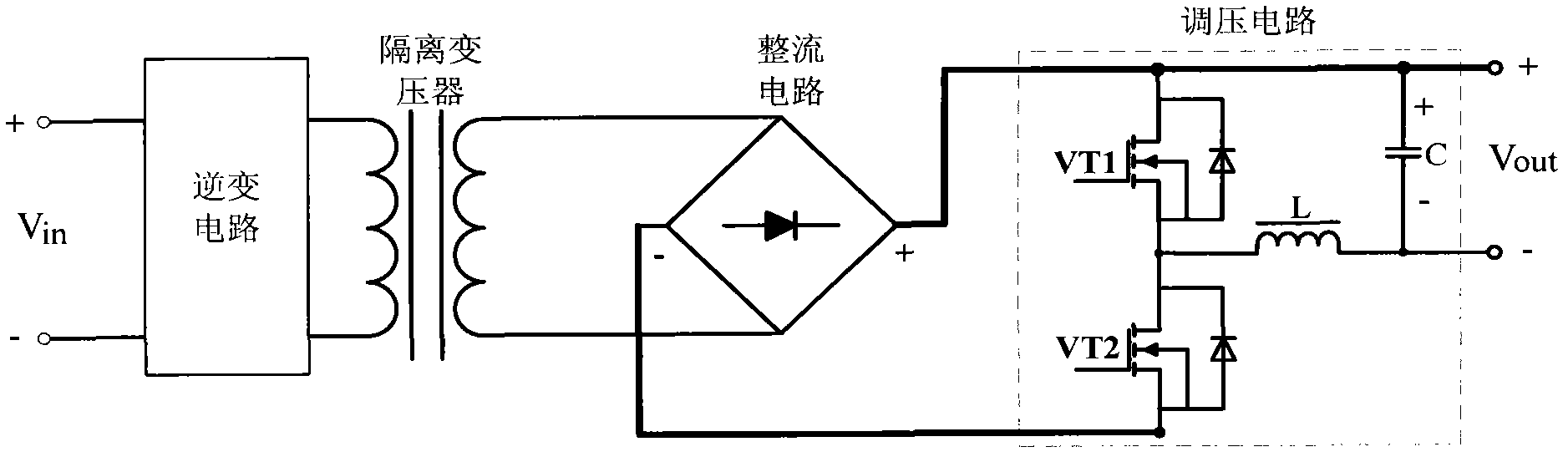

[0066] In this embodiment, the voltage compensation unit does not include an inverter module, a step-down module, and a rectification module, that is, the voltage compensation unit only includes a control module and a voltage regulation module.

[0067] Other structures and functions in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com