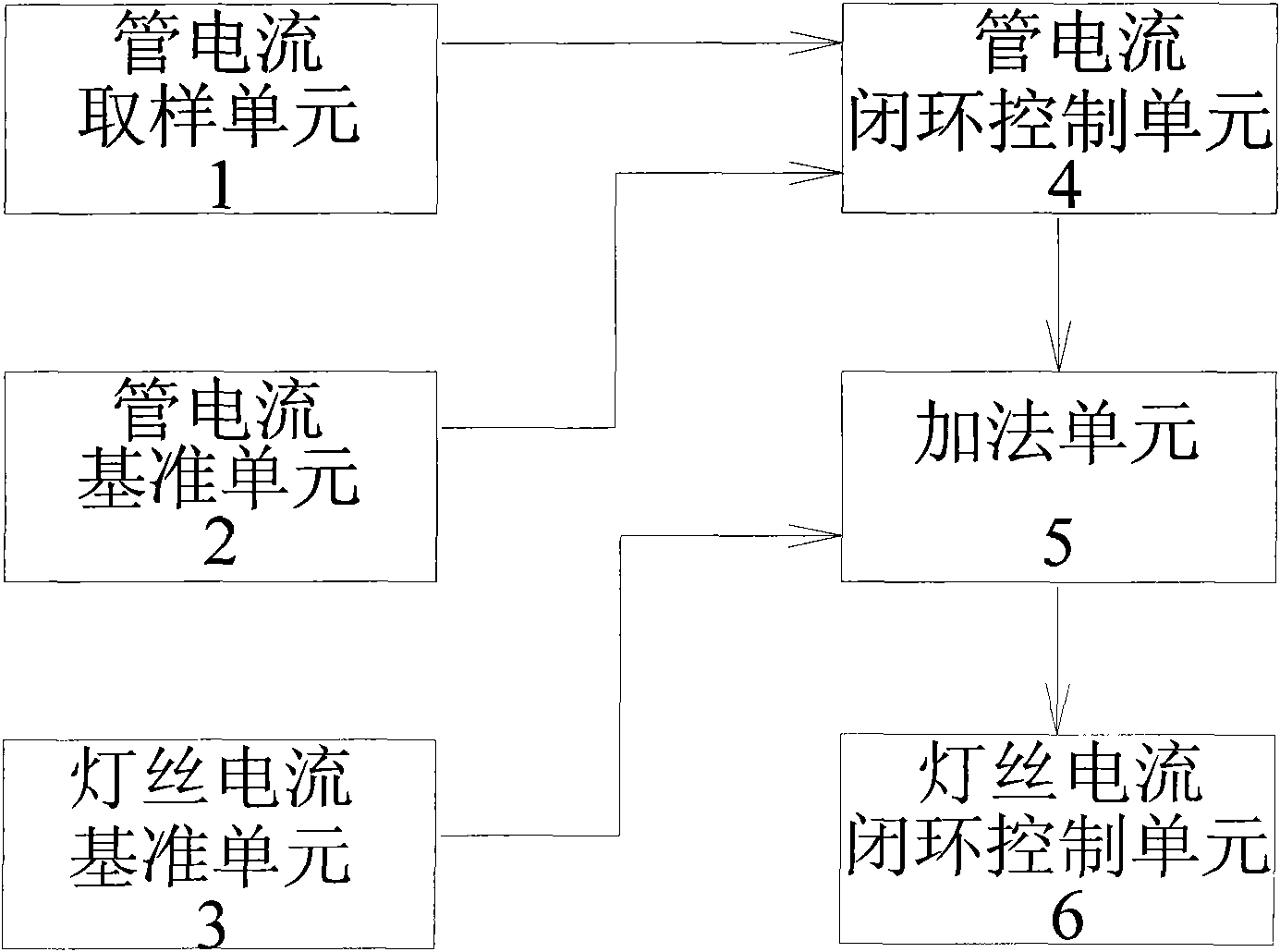

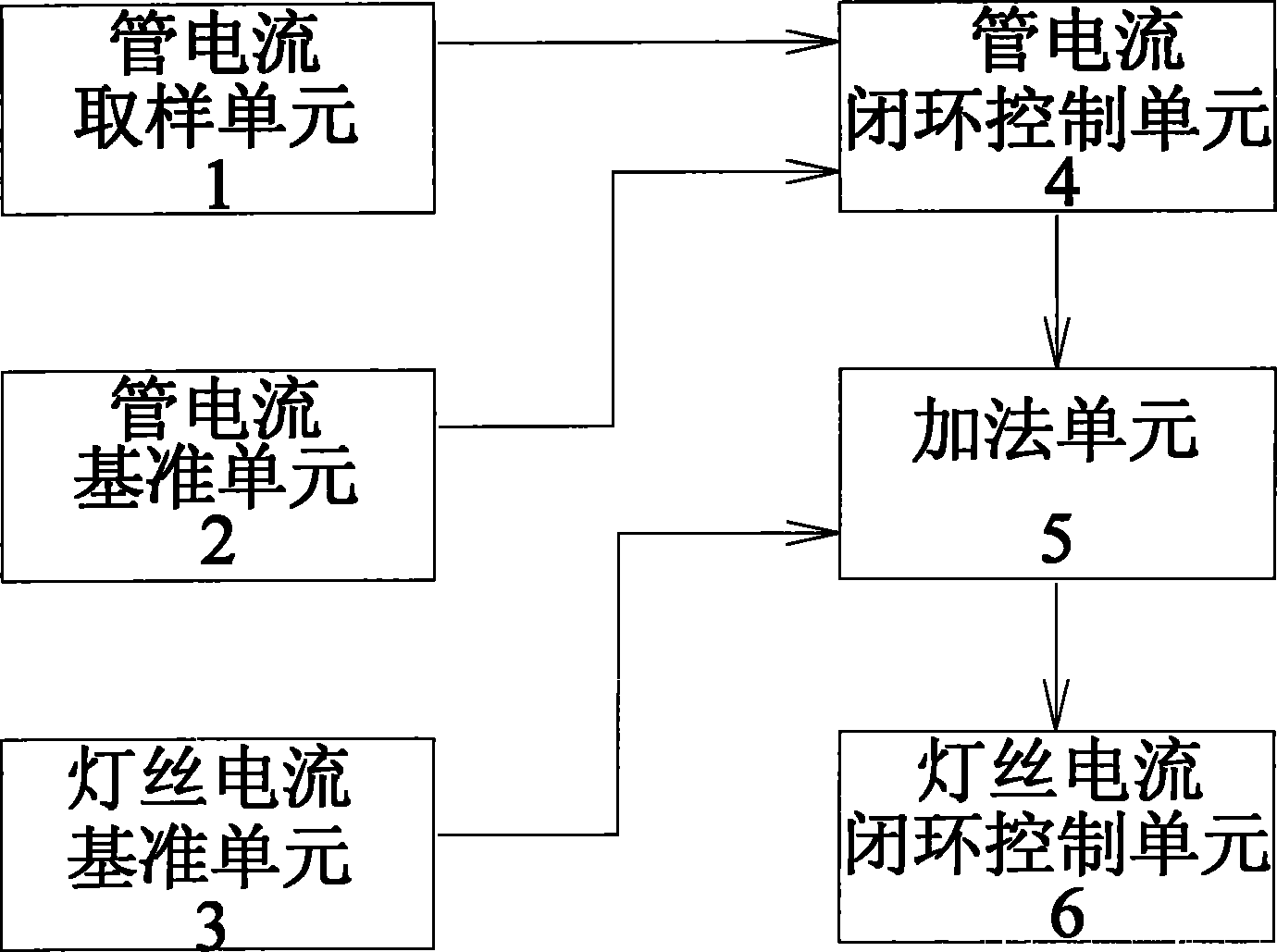

Filament current and tube current dual-closed loop control device for X-ray machine

A filament current and current closed-loop technology, applied in the field of medical equipment, can solve problems such as tube current instability, ray tube overcurrent, affecting image quality, etc., achieve high precision and stability, meet the needs of rapid adjustment and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The device consists of a tube current sampling unit (1), a tube current reference unit (2), a filament current reference unit (3), a tube current closed-loop control unit (4), an adding unit (5), and a filament current closed-loop control unit (6). It consists of six parts, as shown in Figure 1. The tube current closed-loop control unit (4) is an error comparison amplifier circuit with an operational amplifier as the core, and sends the reference voltage of the tube current reference unit (2) to the inverting input terminal of the operational amplifier, and the non-inverting terminal of the operational amplifier is connected to the tube current sampling unit ( 1), the tube current closed-loop control unit (4) sends the amplified error voltage to the addition unit (5) to perform a proportional addition operation, and the signal processed by the addition unit (5) synthesizes the filament reference The signal and the tube current closed-loop signal control the filament cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com