Fiber composite and process of manufacture

A fiber and fiber layer technology, applied in the field of graphite resin composite components, can solve problems such as quality and production problems, and achieve the effects of improving performance, reducing the transmission of impact force, and reducing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

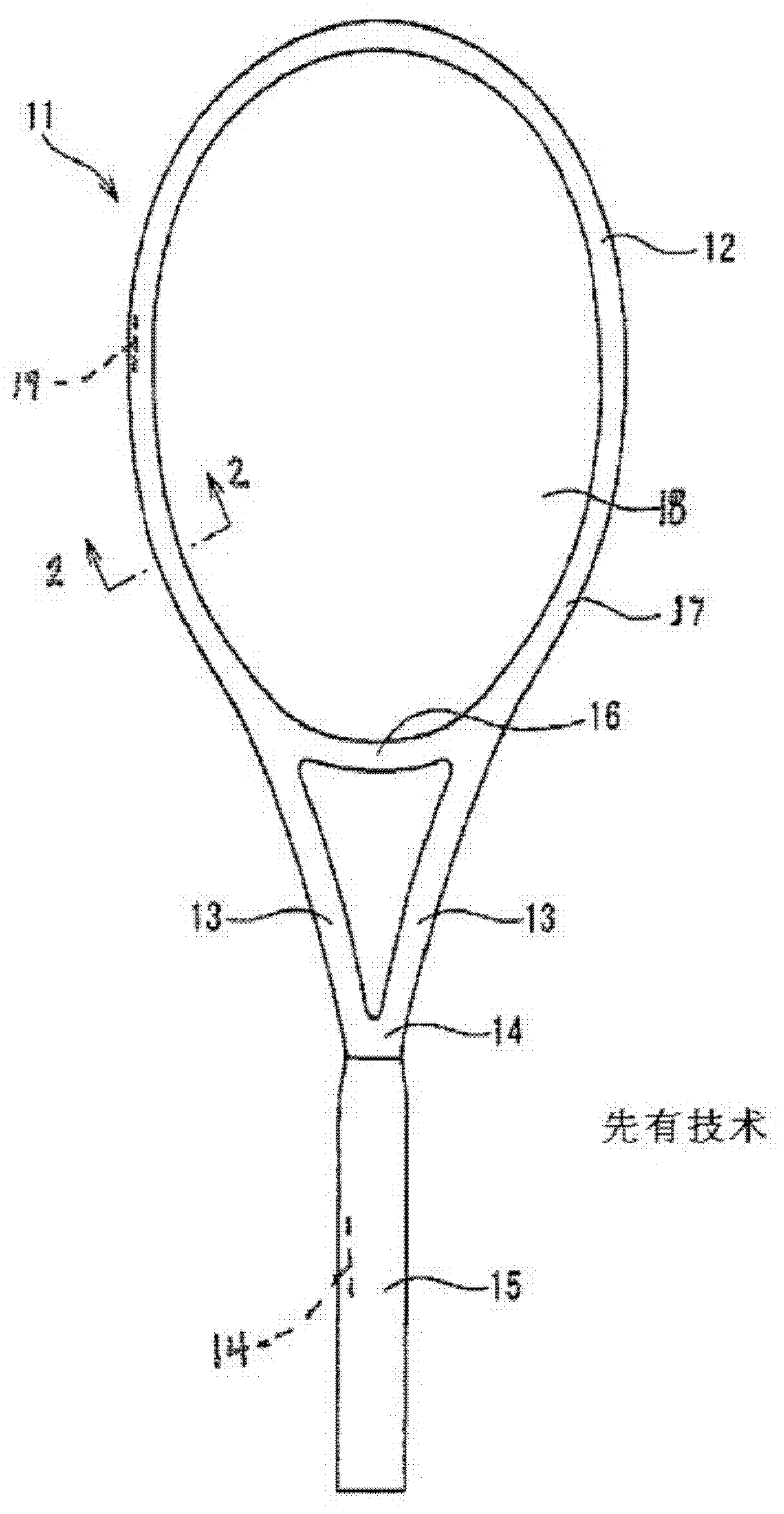

[0099] figure 1 A conventional graphite fiber racquet frame 11 is shown in the current and desired racquet shape. When using the manufacturing technique of air-infused graphite fibers, its weight ratio is more advantageous than previous wooden racquets. The racket frame 11 consists of a racket head 12, a shaft 13, a handle or handle 14, and a bandage 14 wrapped around the handle. These parts of the racket frame 11 are all as independent entities, but are inseparable and continuous components. The two ends 13 of the racket shaft are connected with the racket head 12 and the handle 14 . A bar or yoke portion 16 is interposed between the ends 13 of the shaft. The yoke portion 16 and the head portion 12 form a generally elliptical line around the racquet face 18 . The crimping head 19 is recessed on the outer surface of the racket head portion 12 .

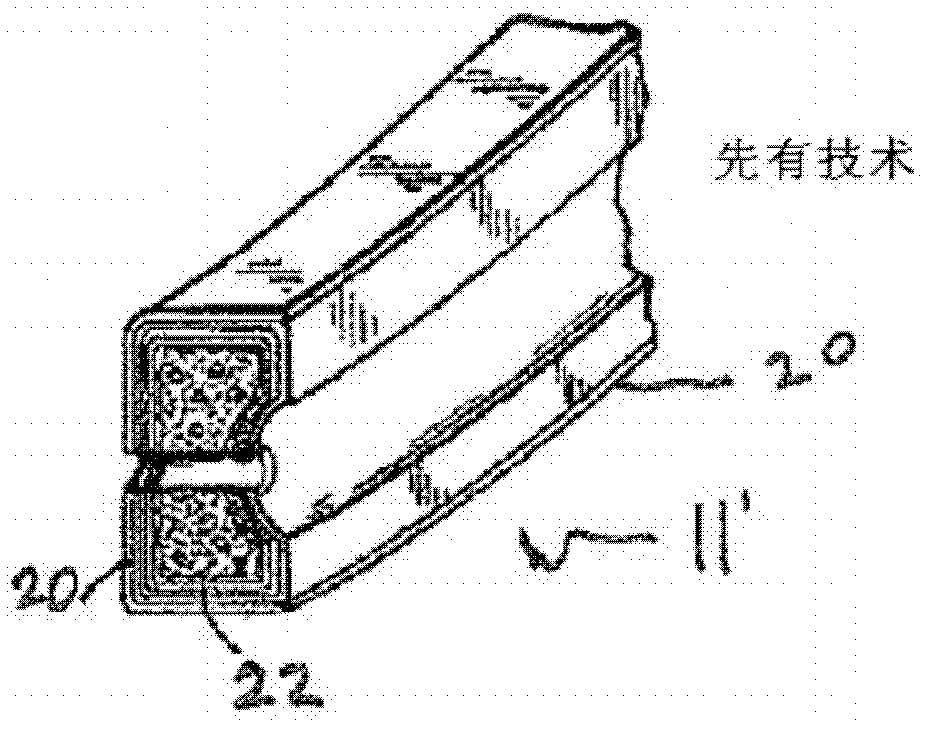

[0100] figure 2 A prior art tennis racquet frame structure is shown, as described in US Patent No. 4,129,634 to Cecka. Here,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com