Device for quickly drying ceramic shell

A fast-drying, ceramic shell technology, used in casting molding equipment, molds, cores, etc., can solve problems such as inability to work, difficult to embed moisture-absorbing materials, and inability to ensure the quality of ceramic shells, and achieve the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

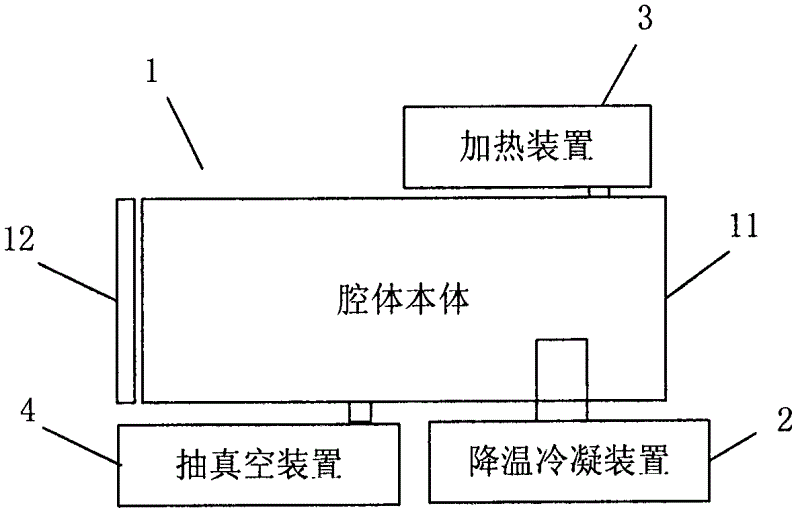

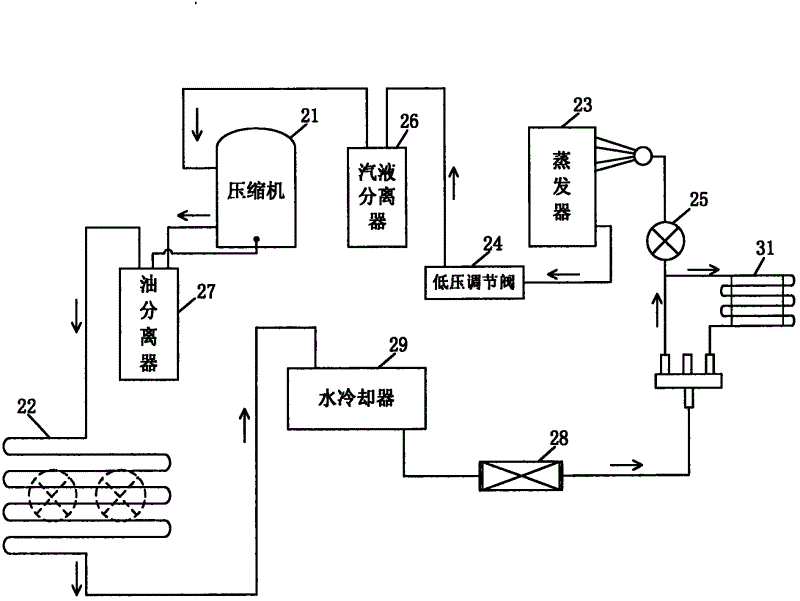

[0055] In order to solve the problem that the ceramic shell drying method in the prior art cannot not only ensure the quality of the ceramic shell but also realize the rapid drying of the ceramic shell when the structure of the ceramic shell is complex, the present invention provides a rapid drying method and device for the ceramic shell, and a ceramic shell drying method and device. shell. The present invention will be described in detail below in conjunction with the accompanying drawings.

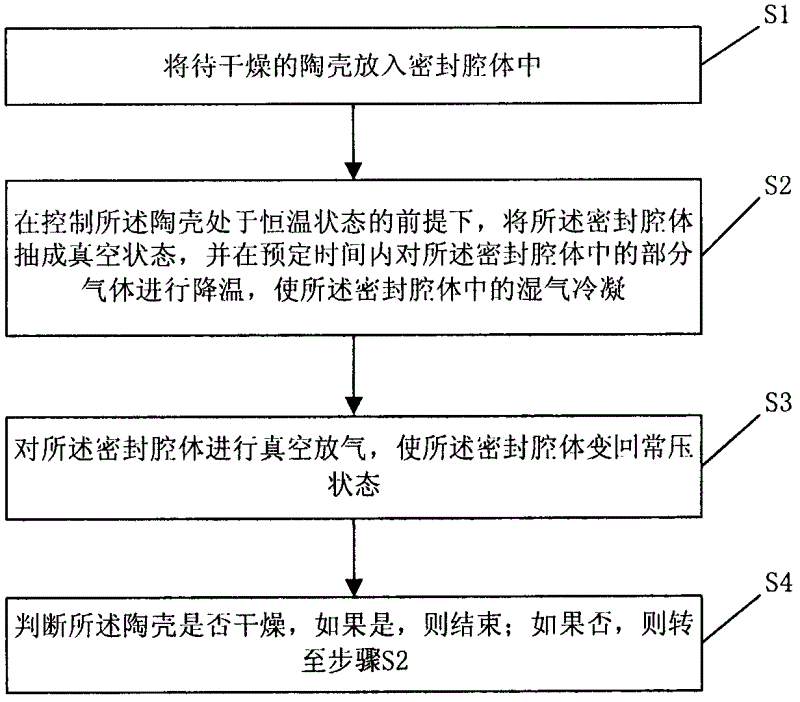

[0056] The invention provides a quick drying method for pottery shells, such as figure 1 As shown, it includes:

[0057] Step S1: Put the pottery shell to be dried into the sealed cavity;

[0058] The sealed cavity is preferably made of metal material.

[0059] Step S2: Under the premise of controlling the ceramic shell to be in a constant temperature state, evacuate the sealed cavity into a vacuum state, and cool down part of the gas in the sealed cavity within a predetermined time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com