An anti-tempering hydrogen welding torch

A technology of hydrogen and welding torch, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc. It can solve the problems of flame returning to the inside of the gas tank, danger, and affecting use efficiency, etc., and achieves a large adjustable range and simple temperature adjustment convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, further illustrate the present invention.

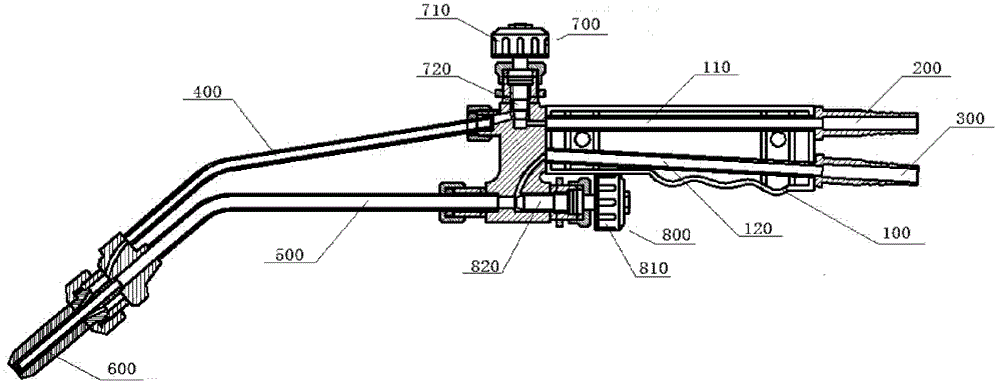

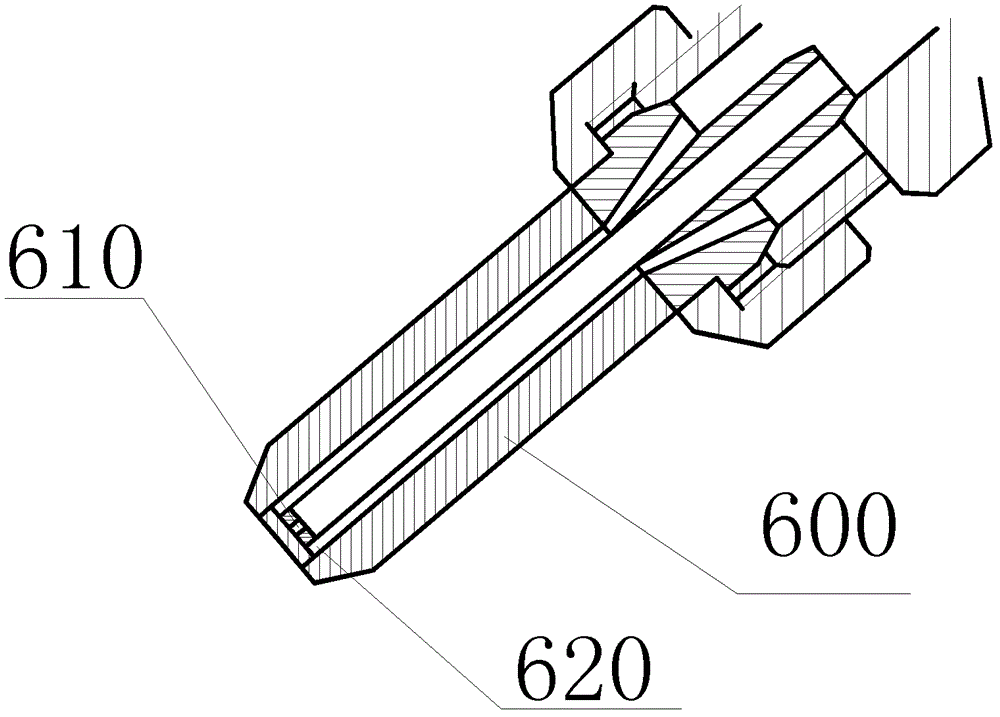

[0016] Such as figure 1 , figure 2 As shown, the anti-tempering hydrogen welding torch of the present invention includes a handle 100, an oxygen inlet pipe 200, a hydrogen inlet pipe 300, an oxygen outlet pipe 400, a hydrogen outlet pipe 500, a nozzle 600, an oxygen regulating valve 700 and a hydrogen regulating valve 800.

[0017] The handle 100 is provided with an oxygen channel 110 and a hydrogen channel 120 respectively. One end of the oxygen channel 110 is connected with the oxygen inlet tube 200, and the other end is connected with the oxygen outlet tube 400. The hydrogen channel 120 is connected with the hydrogen inlet tube 300, and the other end is connected with the The hydrogen outlet pipes 500 are in communication.

[0018] The oxygen regulating valve 700 includes an adjusting wheel 710 and an adjusting column 720, which is installed at the junction of the oxygen pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com