Tin-based lead-free solder and preparation method thereof

A technology based on lead-free solder and lead-free solder, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of easy peeling of solder joints, dendrite segregation, coarsening of structure, etc., and achieve excellent ductility properties, high tensile strength, improved wetting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

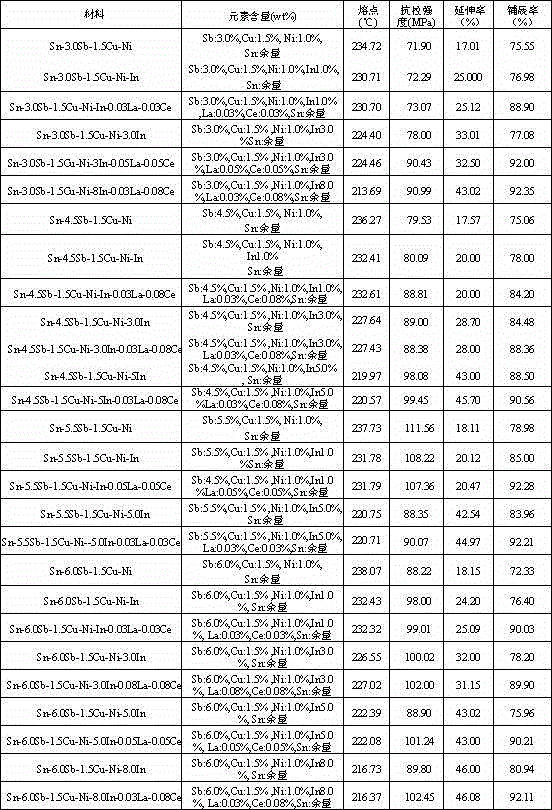

[0025] According to the above preparation method of the present invention, the components and properties of the prepared solder alloy and their comparison are shown in the following table.

[0026] It can be seen from the table below that the melting point of the alloy solder increases with the increase of the addition of Sb; with the increase of the addition of In, the melting point of the solder alloy is reduced, and the plasticity of the solder also shows a tendency to increase; and the addition of rare earth has an effect on the melting point of the alloy. The effect is not big, but a proper amount of rare earth can improve the wettability of the alloy very well.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com