Carbon fiber three-dimensional forming device

A three-dimensional forming and carbon fiber technology, which is applied in the field of manufacturing process and mold matching devices, can solve the problems of inability to process large quantities and stably, long production cycle, cumbersome manufacturing process, etc., and achieve the effect of shortening the production cycle, fast production speed and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

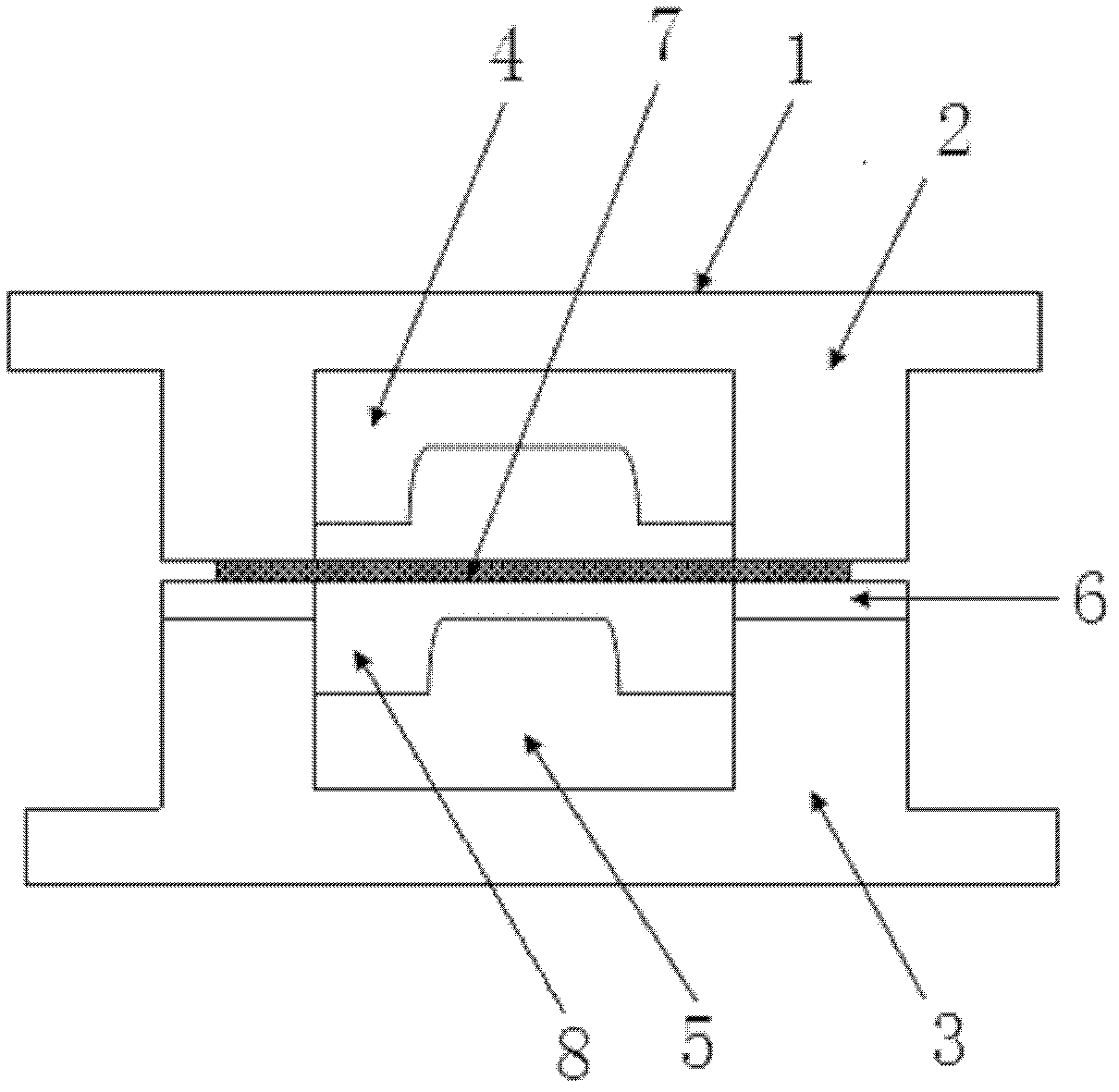

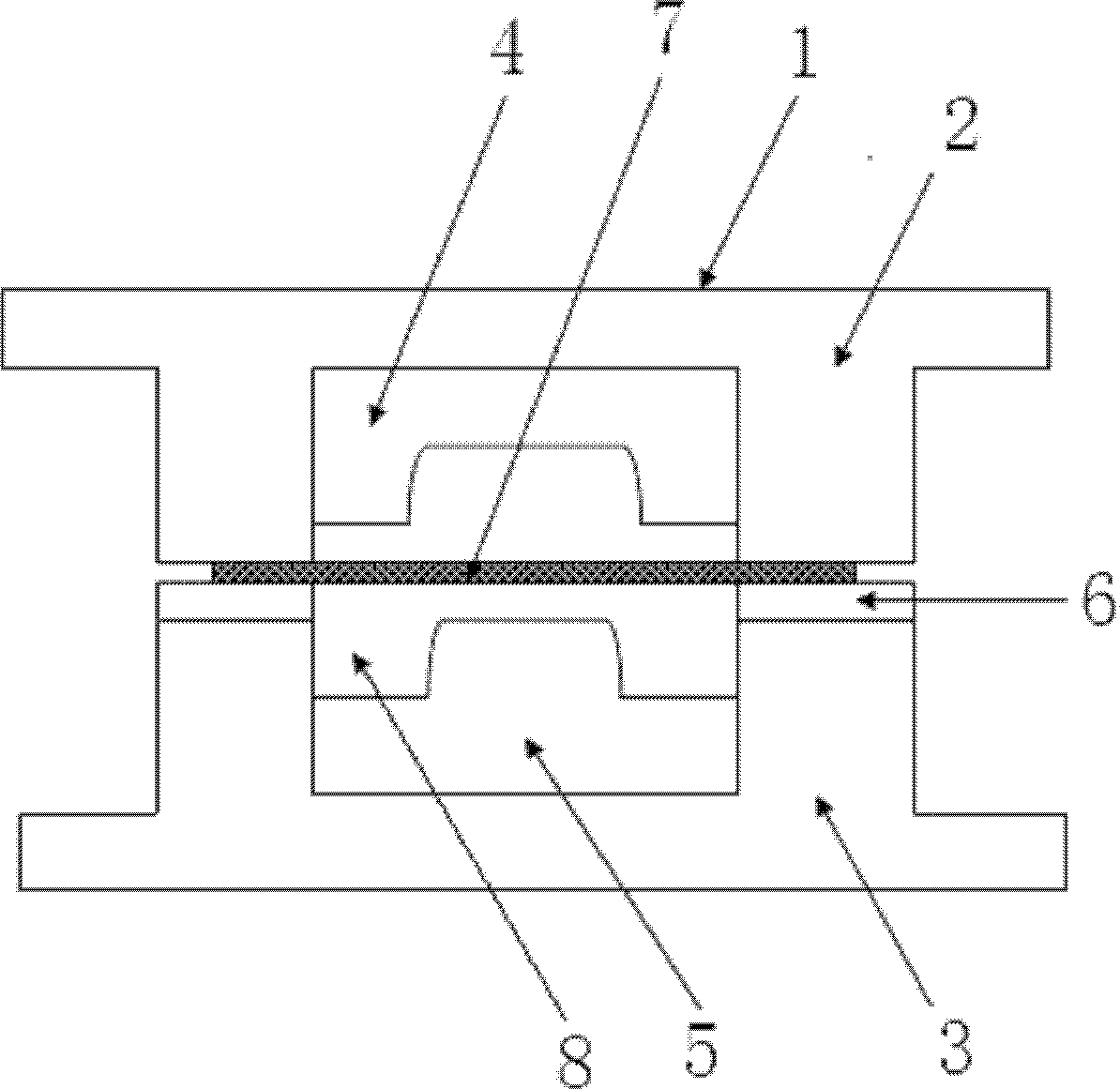

[0012] Such as figure 1 As shown, a carbon fiber three-dimensional forming device includes a mold 1, high-pressure equipment, vacuum equipment and heating equipment. The mold includes an upper mold base 2, a lower mold base 3, and an upper mold core 4 locked in the upper mold base 2. , the lower molding mold core 5 locked in the lower mold base 3, the upper molding mold core 4 and the lower molding mold core 5 are relatively positioned to form a cavity 8, and the cavity 8 is connected to the high-pressure equipment and vacuum equipment respectively. On the surface of the mold base 3, positioning splints 6 are arranged on both sides of the lower molding die core 5, the upper surface of the positioning splint 6 and the upper surface of the lower molding die core 3 are located on the same straight line, the positioning splints 6 on both sides and the middle lower die The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com