Nano computer to plate (CTP) ink head lifting device

A lifting device and machine ink technology, applied in power transmission device, printing plate preparation, printing, etc., can solve the problems of high cost, complex structure, ink head lifting device not suitable for nano-plate, etc., to achieve small occupied space and realize The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

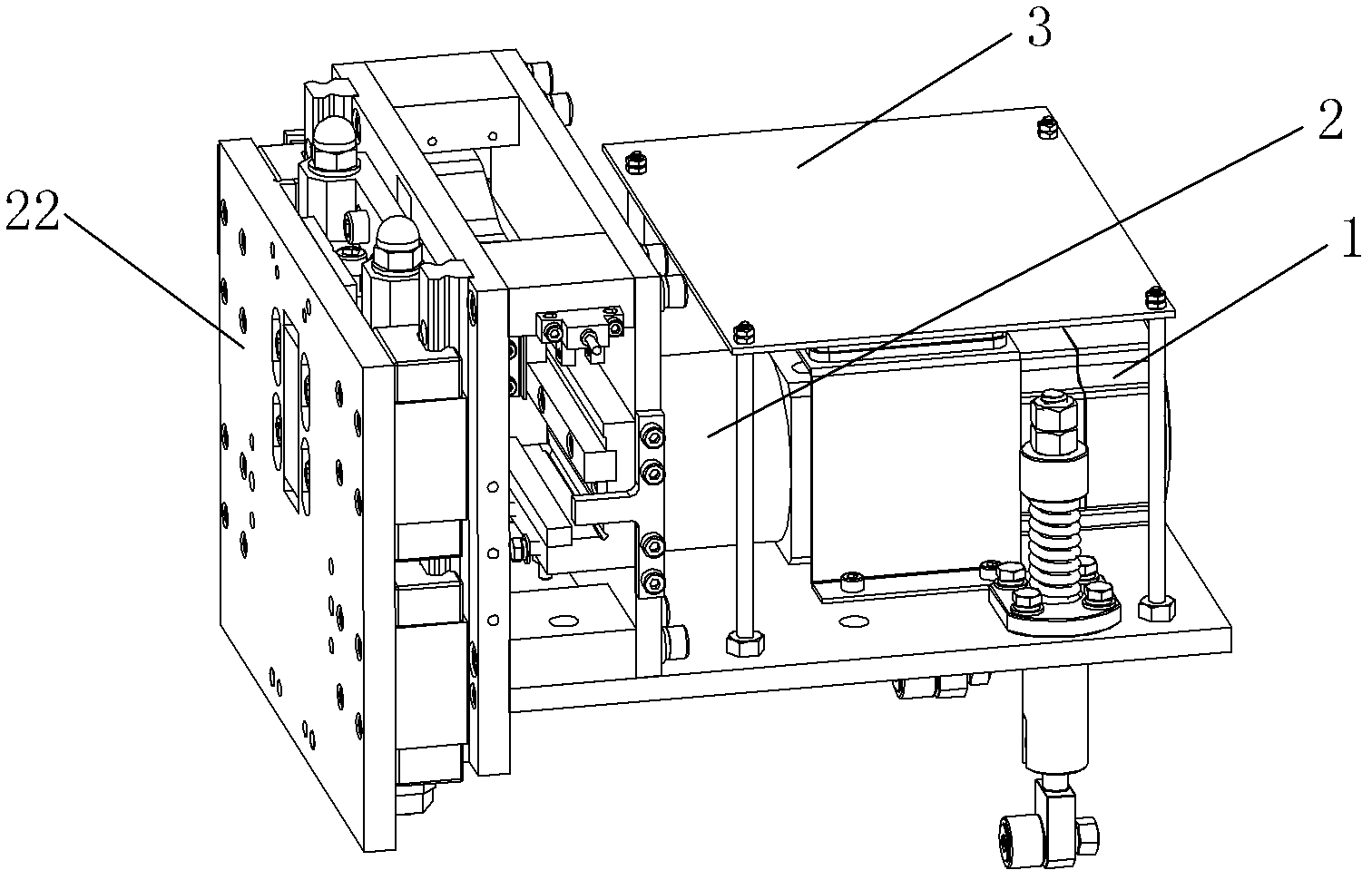

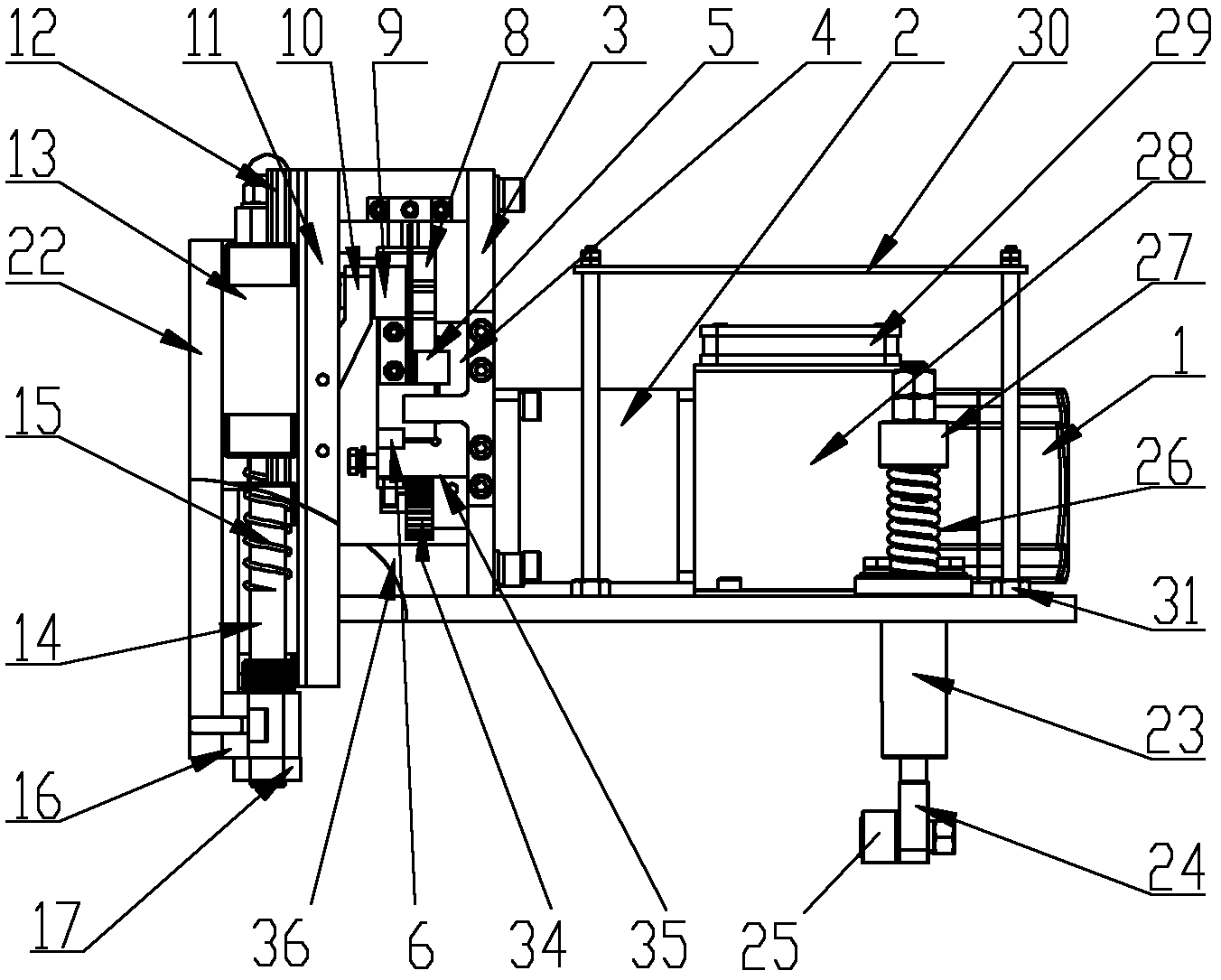

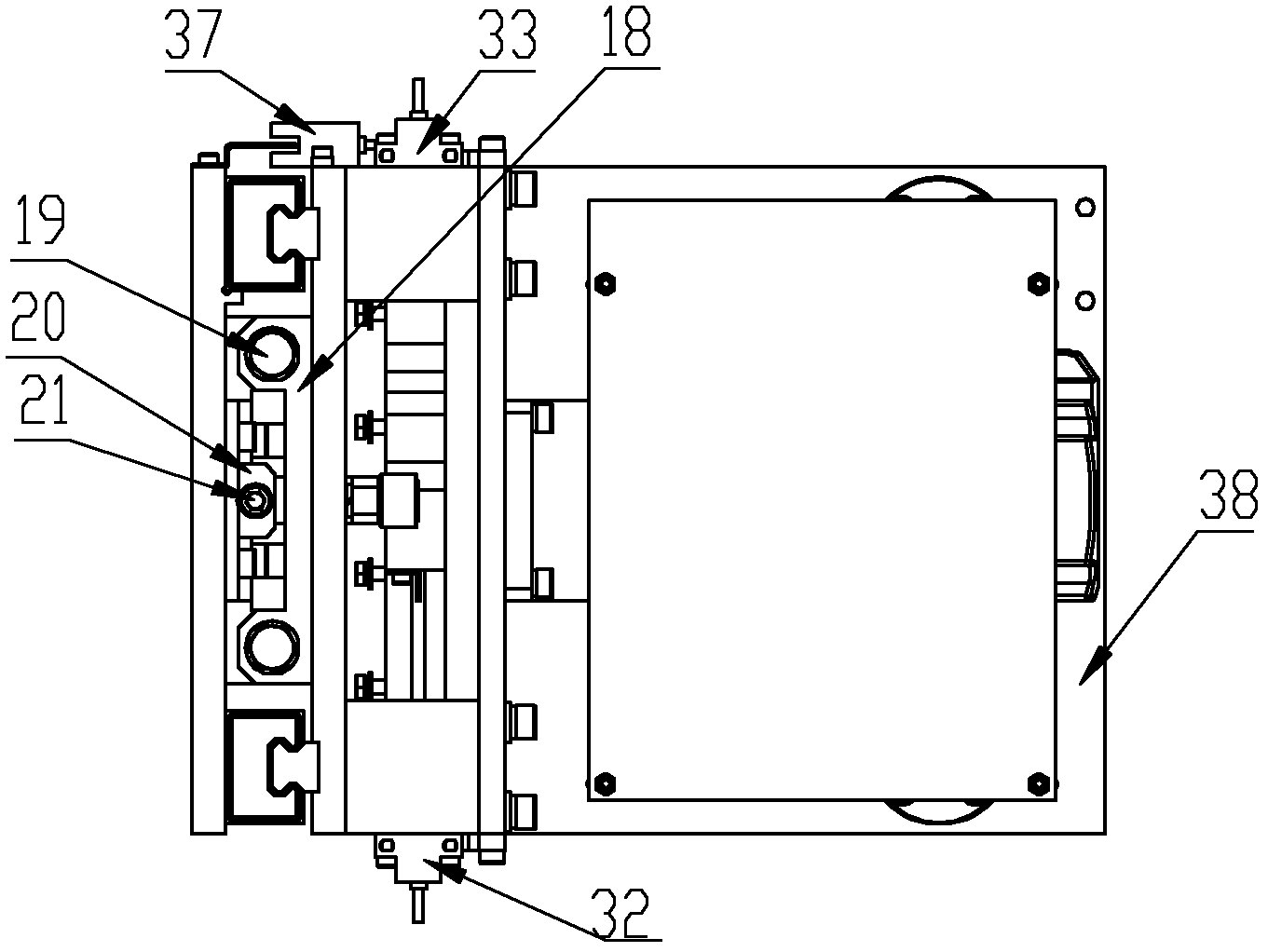

[0021] Example: such as figure 1 , figure 2 As shown, the present invention includes a drive mechanism, a transmission adjustment mechanism, a middle plate 11, a sliding plate 22 and a positioning mechanism. The drive mechanism is placed on the base plate 38, and one end of the transmission adjustment mechanism is meshed with the gear 34 of the drive mechanism through its veneer cam 8. The other end is installed on the sliding plate 22 through the roller seat body 10, the middle plate 11 is installed on the main board 3 of the transmission adjustment mechanism, one end of the positioning mechanism is connected with the middle plate 11, and the other end is connected with the sliding plate 22, and the sliding plate 22 and The middle boards 11 are connected by two second slide rail assemblies. During installation, the inkjet circuit board 30 is placed on the bottom board 38 through the struts 31 .

[0022] The transmission adjustment mechanism described in this example include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com