Process for producing hollow glass

A production process and glass technology, applied in the field of insulating glass production technology, can solve the problems of difficulty in ensuring the air tightness of insulating glass, low content of equipment branches, complicated production process, etc., and achieves smooth and smooth appearance, good air tightness, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

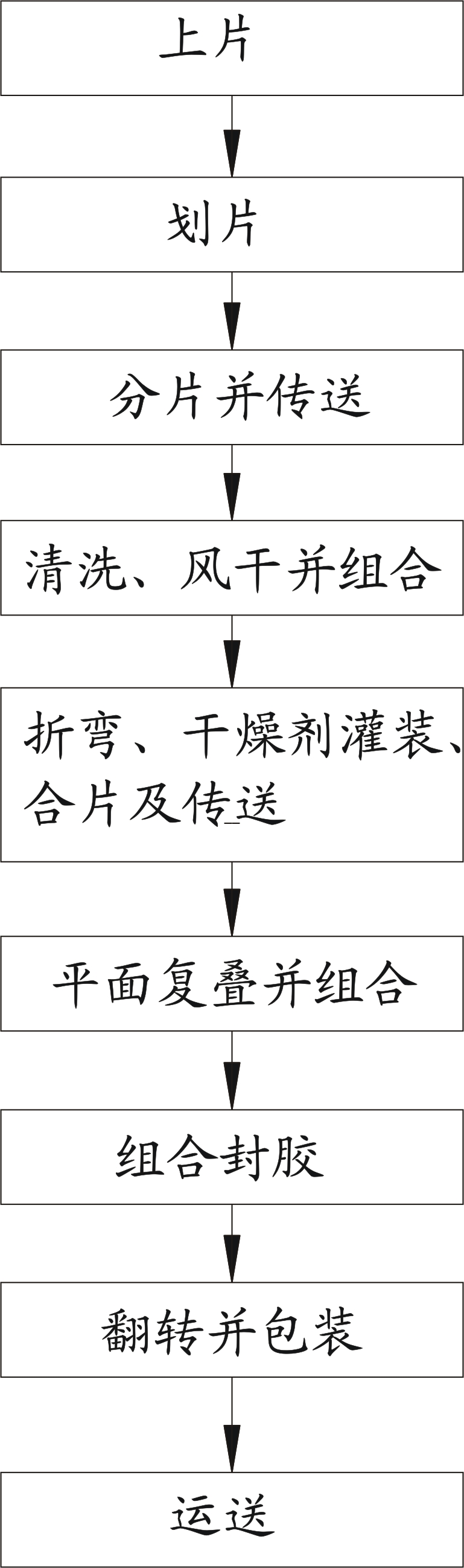

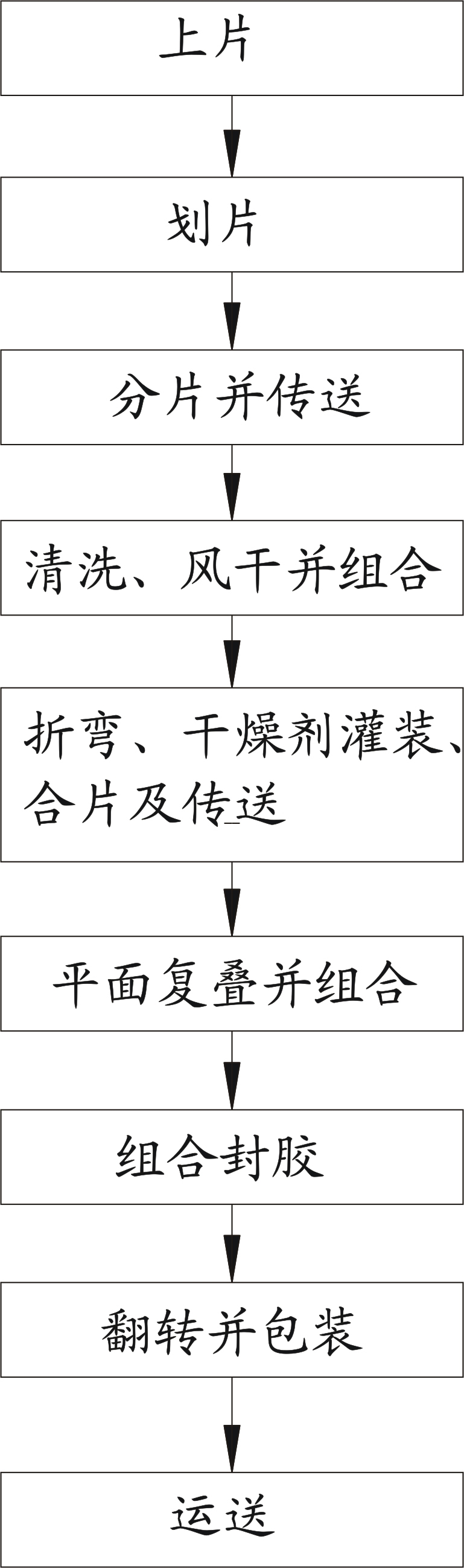

[0020] As an embodiment of the hollow glass production process of the present invention, such as figure 1 shown, including the following steps:

[0021] ⑴. The glass to be processed is loaded through the automatic glass loading system;

[0022] ⑵. Carry out slicing operation through automatic glass scribing system;

[0023] ⑶. Segment and transmit the glass through the slicing and conveying device;

[0024] ⑷. The glass is cleaned and dried by the glass cleaning and air-drying system first, and then the fully automatic combination operation is performed;

[0025] ⑸. Fully automatic combination and continuous operation through inner frame bending, desiccant filling, glass combination and transmission system;

[0026] ⑹. Carry out plane cascade and combine operations on the glass through the glass plane cascade assembly device;

[0027] ⑺. Through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com