Damping jacket for railway rail and assembly method thereof

An assembly method and sheath technology are applied in the field of rail vibration and noise reduction, which can solve the problems of strong visual impact, unsatisfactory effect, and high installation cost, and achieve the effects of long service life, good shock absorption and noise reduction performance, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

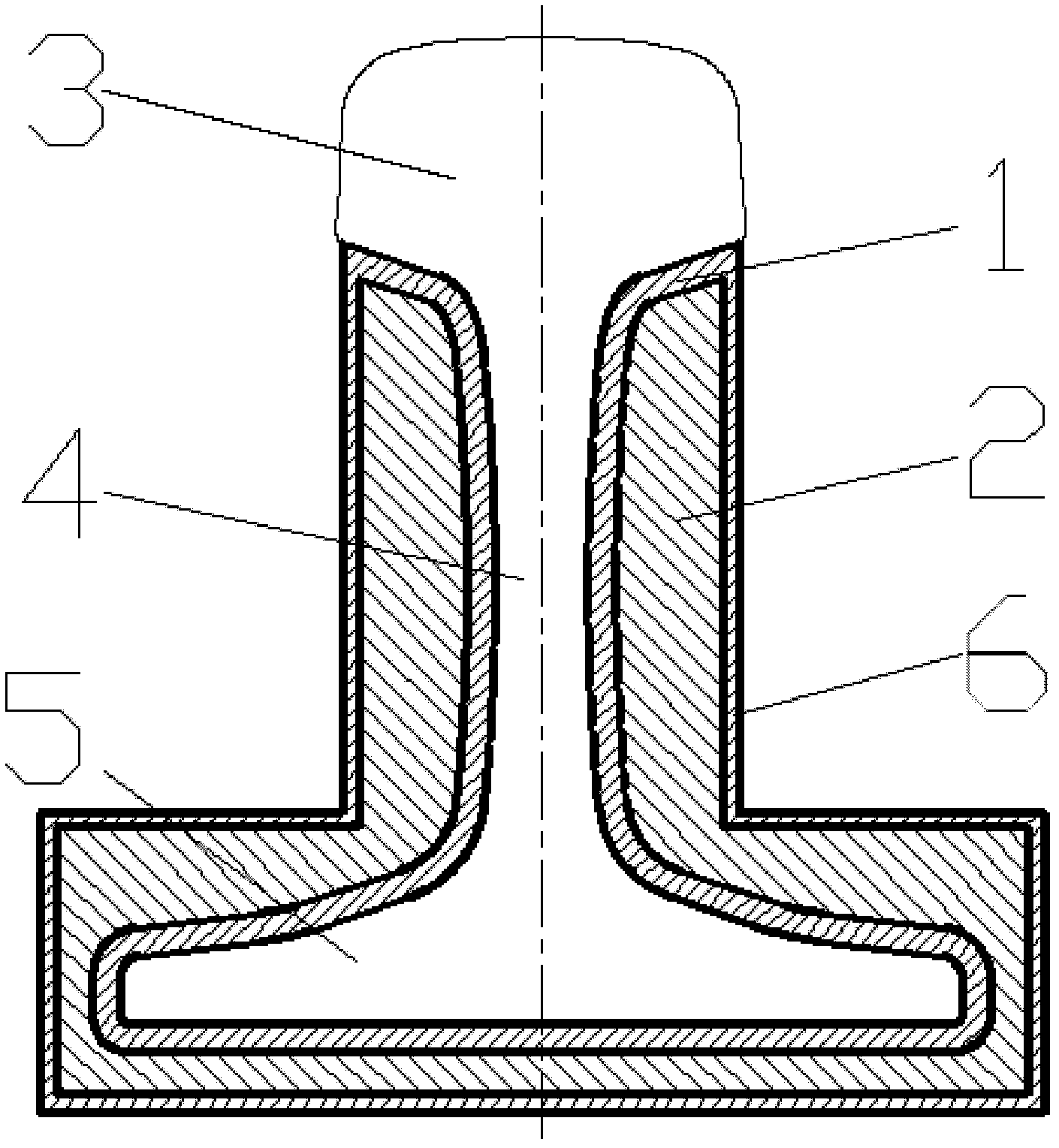

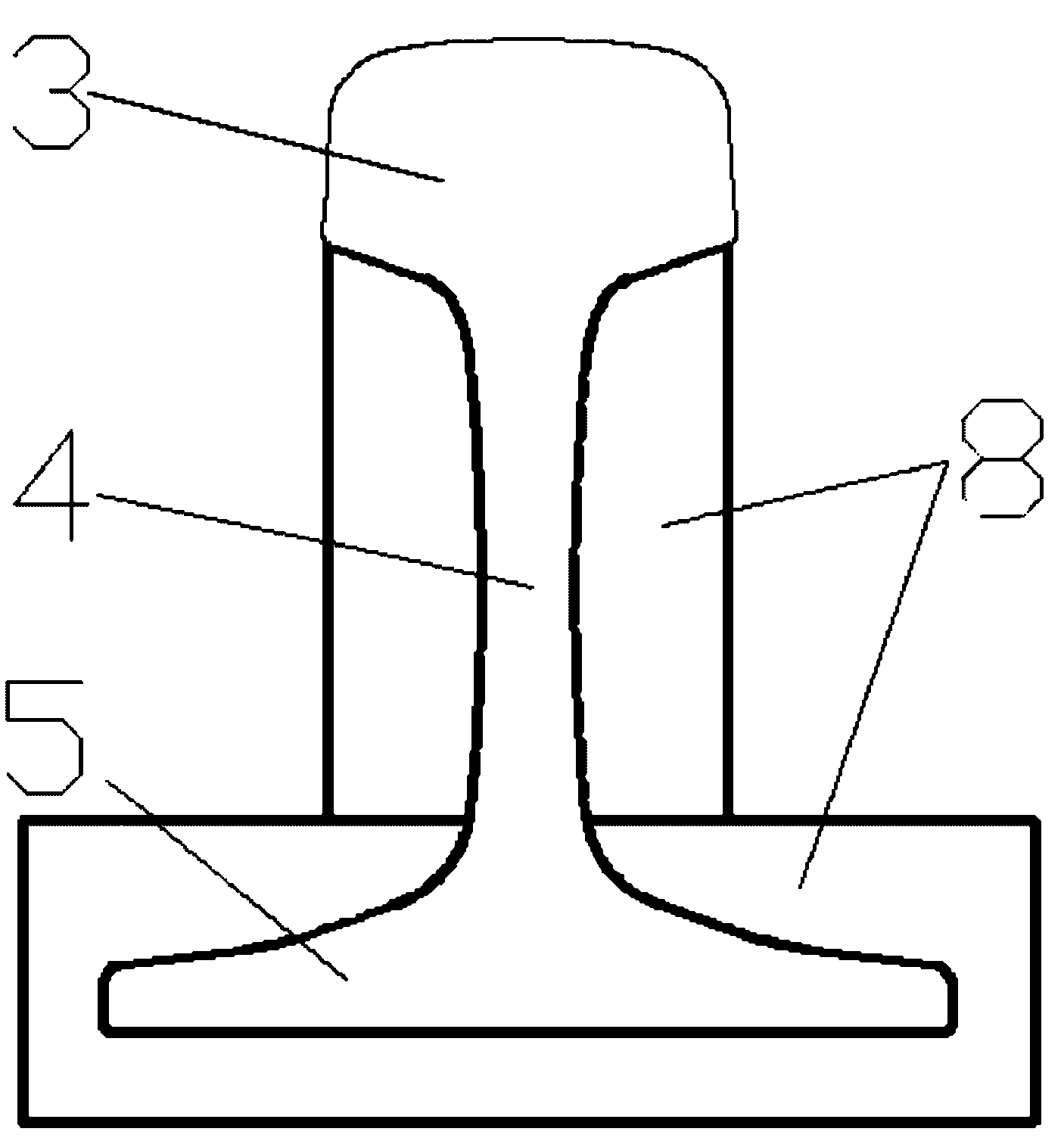

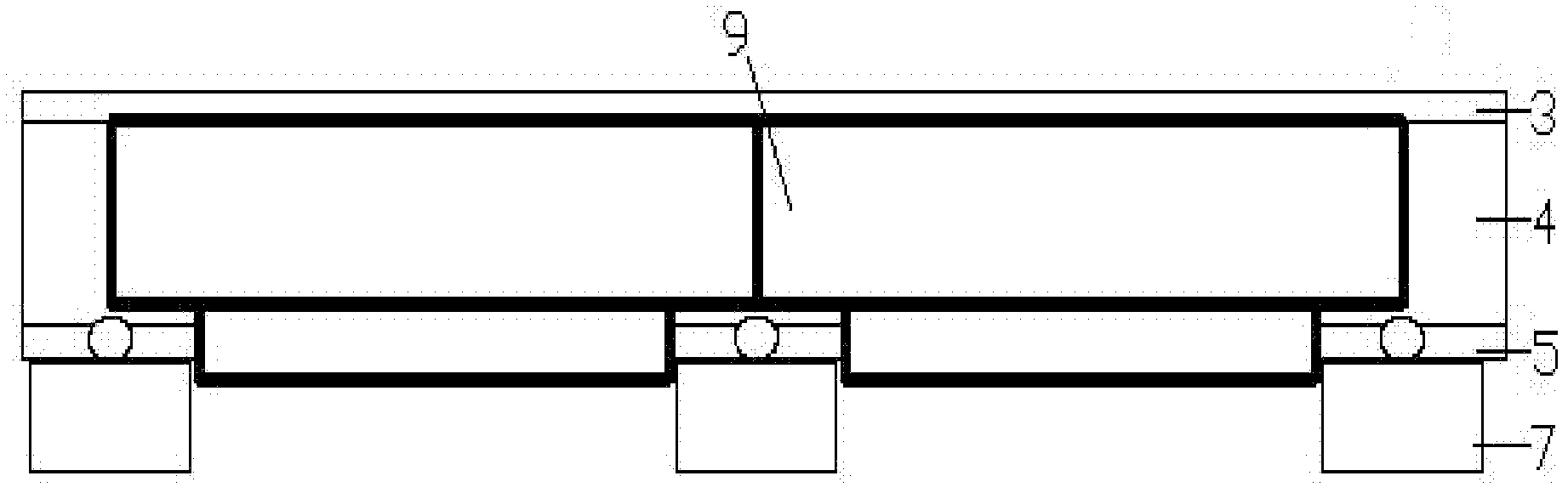

[0053] Such as Figures 1 to 3 As shown, a damping sheath for railway rails includes an expansion layer 1 that is closely attached to the rail bottom 5 and rail waist 4 of the railway rail 3, and a cladding layer 6 is arranged on the outside of the expansion layer 1; the expansion layer 1 and both ends of the coating layer 6 are provided with a sealing layer 8; the expansion layer 1, the coating layer 8 and the sealing layer 8 form a closed space, and the closed space is filled with liquid damping material to form Damping layer 2.

[0054] The liquid damping material is liquid epoxy damping material.

[0055] The distance between the cladding layer 6 and the expansion layer 1 at the thinner portion corresponding to the rail waist 4 and the rail bottom 5 is greater than the distance between the cladding layer 6 and the expansion layer 1 at the thicker portion.

[0056] The expansion layer 1 in contact with the rail waist 4 of the railway rail 3 extends to both ends along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com