Soil screw traction self-traveling type tunnel piercing device and piercing method

A tunneling, self-propelled technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve problems such as application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

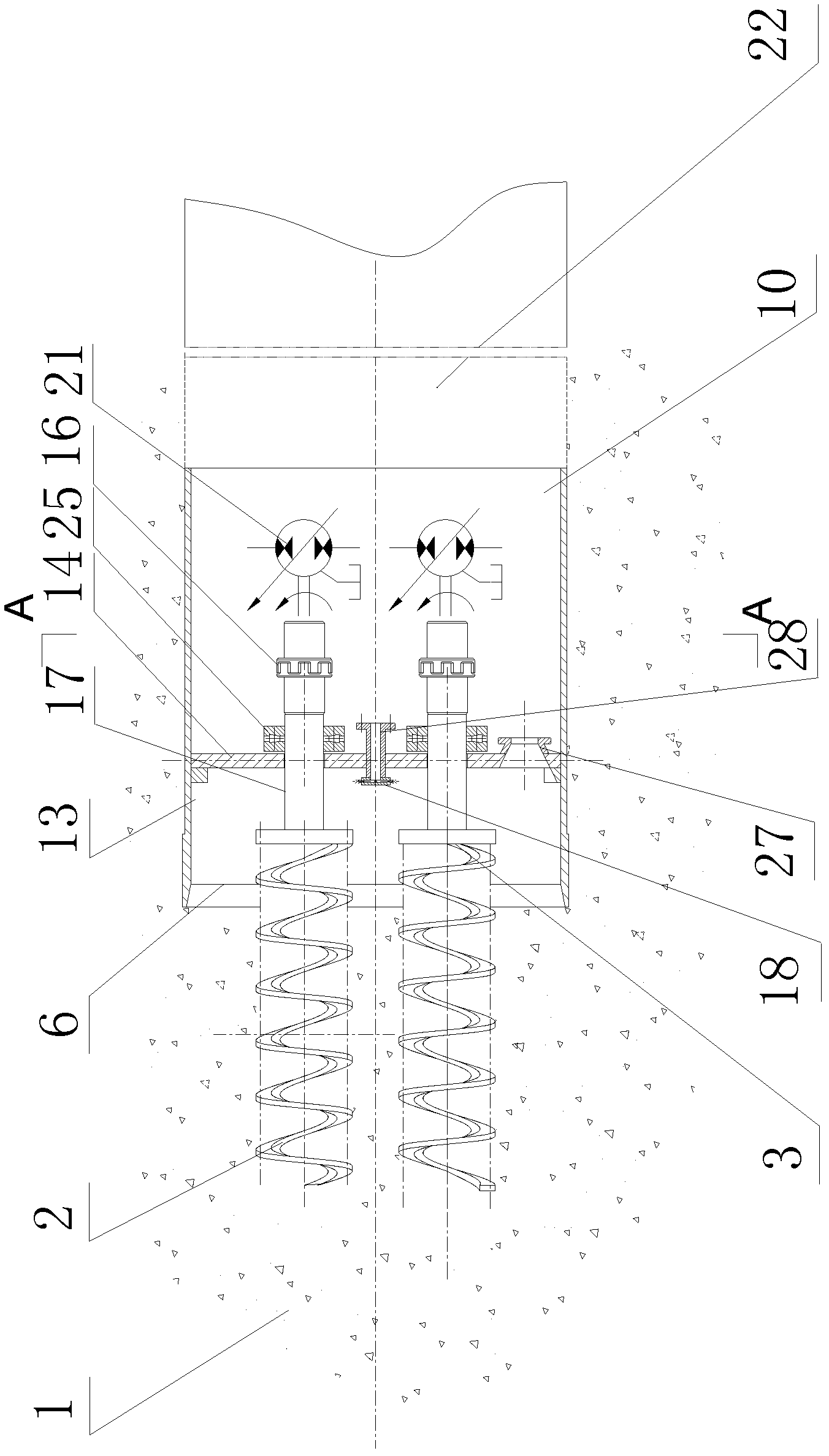

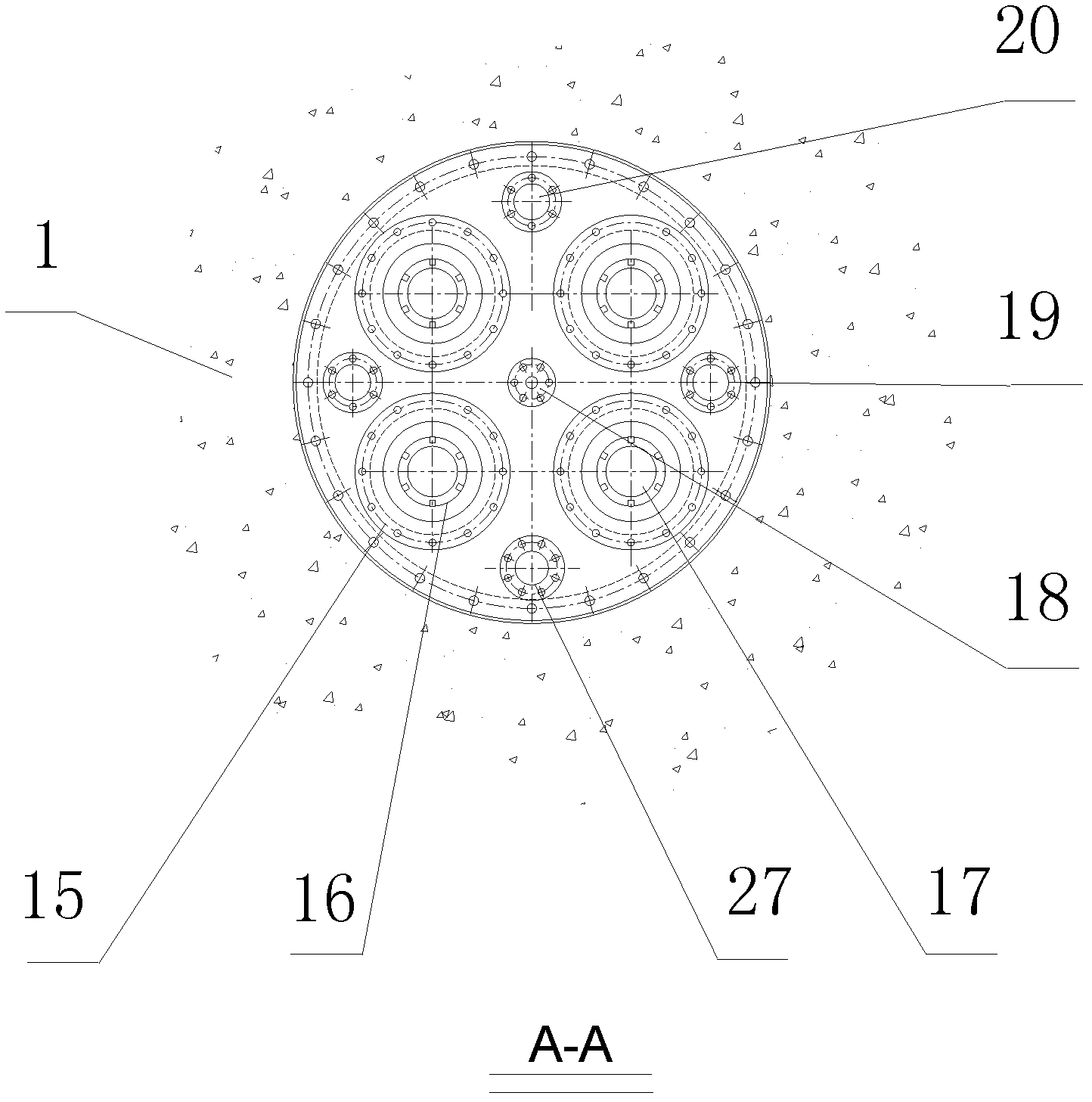

[0031] like figure 1 As shown: one or more spiral pullers 2 are installed at the front end of the first section 10 of the roadheader, through the spiral connecting disc 3 connected with the 2, and then through the spiral puller shaft 17, connected with the coupling 16, the joint The shaft device 16 is connected with the torque driving source 21, and under the action of the torque provided by 21, it drives the screw puller 2 to rotate in the soil body 1 in front of the working face, and the rotation of the screw puller 2 in the soil body 1 generates The pulling axial force in front of the working face of the roadheader, the pulling axial force is transmitted to the thrust bearing 25 through the helical pulling shaft 17, pushing the partition plate 14 solidly connected with the first section 10 of the roadheader to move forward, thereby driving the second One section 10 moves forward, completes the forward movement of the first section 10 of the roadheader. The soil body 1 in f...

Embodiment 2

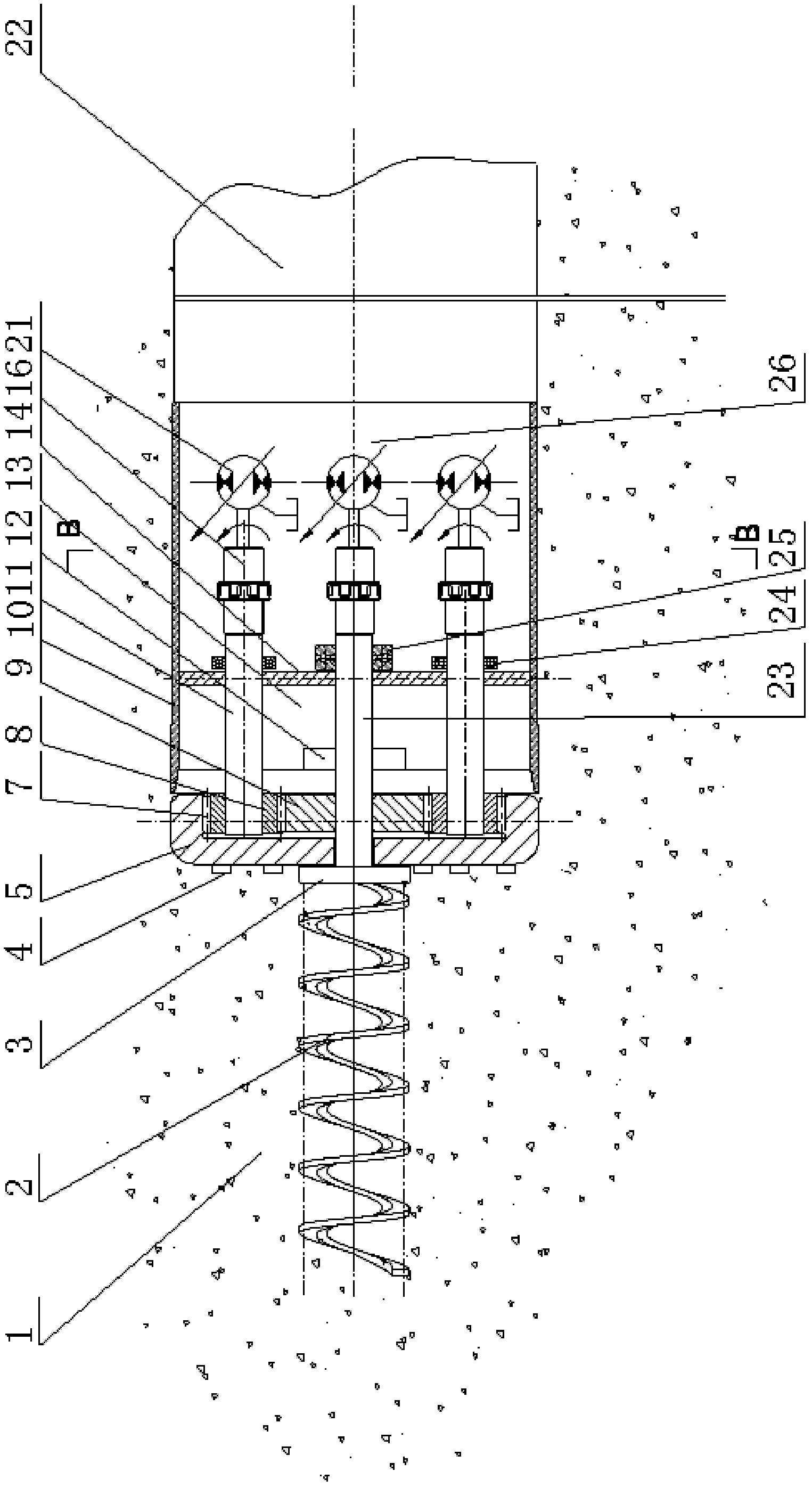

[0033] like figure 2 As shown, a cutting cutter head 5 is installed at the front end of the first section of the casing 10 of the roadheader. The cutting tool 4 for cutting the soil body 1 is installed on the cutting cutter head 5. The transmission meshing teeth 7 on the cutting cutter head 5 are meshed with it. The cutter head drive gear 8 is driven, and the cutter head drive gear 8 is connected to the torque drive source 21 through the bearing 24, the cutter head drive shaft 11, and the shaft coupling 16, so as to drive the cutting tool 4 on the cutting cutter head 5 to cut the soil body 1. The leading helical puller 2 protruding into the soil 1 is connected to the torque drive source 21 located in the working room 26 behind the roadheader through the leading helical puller shaft 23 through the helical connecting disc 3 connected to it. Driven by the torque drive source 21, the leading helical puller 2 rotates in the soil body 1, acts on the partition plate 14 through the t...

Embodiment 3

[0035] like image 3As shown, a cutting cutterhead 5 is installed at the front end of the roadheader housing 10, and a cutting tool 4 for cutting the soil body 1 is installed on the cutting cutterhead 5. The driving wheel 9 is driven, the cutter head driving gear 9 is connected with the torque driving source 21 arranged in the working room 26 of the front section of the roadheader through the central shaft 23, and the shaft coupling 16. Under the action of the rotation of the torque drive source 21, through the coupling 16, the central shaft 23, the helical connecting disc 3 drives the leading helical puller 2 to rotate and screw into the soil body 1, and the pulling drive shaft 23 acts on the soil bin partition 14 On the thrust bearing 25 on the top, the boring machine casing 10 is moved forward. While driving the central shaft 23 to rotate, the cutter head drive gear 9 drives the cutting cutter head 5 to rotate through the cutter head drive gear 8, so that the cutting tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com