Pressure-adjustable mine high- and low-pressure water energy exchange system

A switching system, high and low pressure technology, applied in mining equipment, mine/tunnel ventilation, earthwork drilling and mining, etc., can solve the problems that cannot guarantee the continuous and stable operation of the system, shorten the service life of valves, and deteriorate the working environment of valves, etc., to achieve The effect of improving service life, reducing operating energy consumption, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

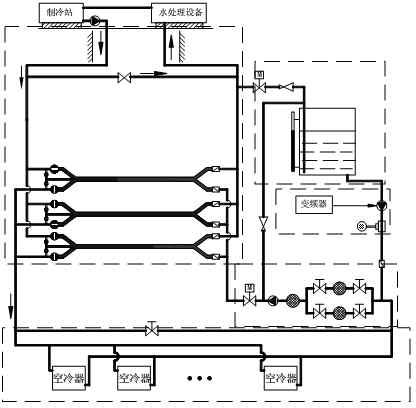

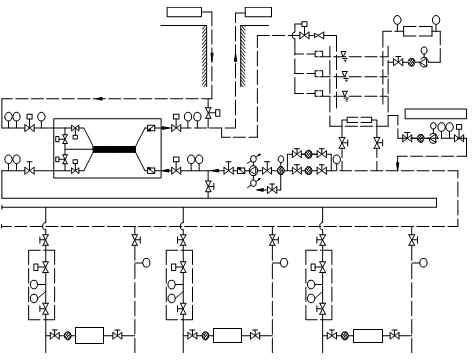

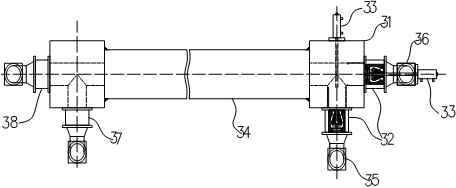

[0037] figure 1 It is the schematic diagram of the high and low pressure water energy exchange system; figure 2 It is a diagram of the cooling system with the high and low pressure conversion device as the core; image 3 It is the connection diagram of the cavity pipe and the three-way water distributor and the connection diagram of the hydraulic valve and the three-way water distributor; Figure 4 It is the principle block diagram of the high and low pressure water energy exchange system; Figure 5 It is a connection block diagram of the high and low pressure water energy exchange system; Image 6 It is the structure diagram of the hydraulic control valve; Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com