Calipers flange welded type bellows

A flange welding and bellows technology, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of high engineering cost and defective rate, inconvenient installation, poor sealing, etc. Improve quality yield, easy and fast installation, and increase the effect of tension and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

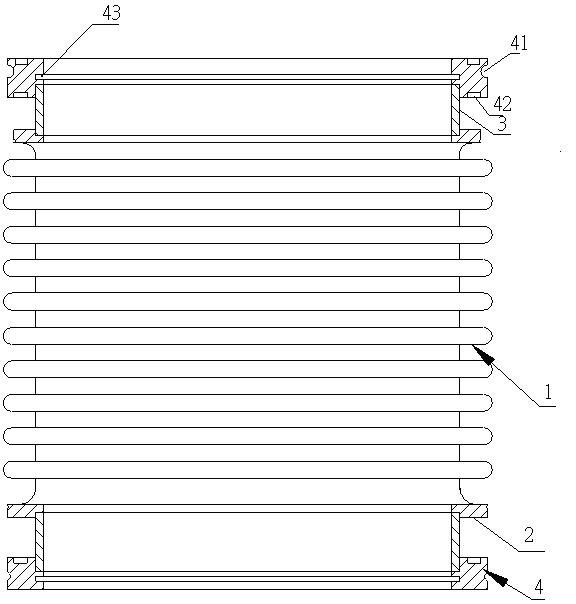

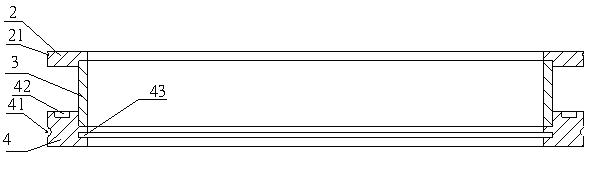

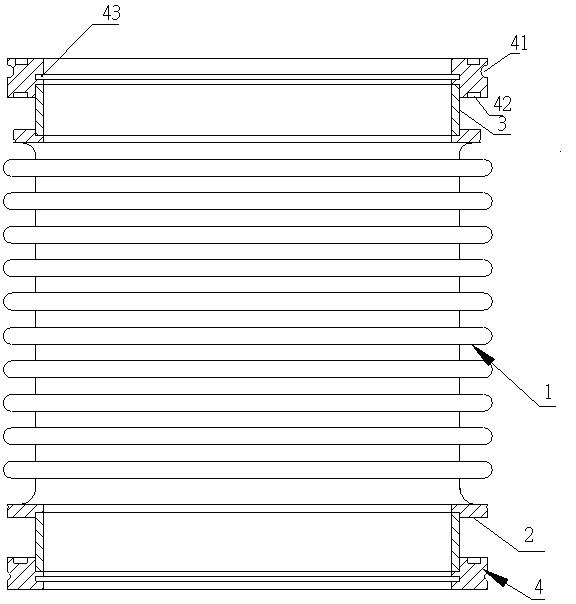

[0016] see figure 1 and figure 2 , a caliper flange welded bellows in this embodiment, which includes a bellows 1, a connecting end provided at both ends of the bellows 1, and a caliper flange 4 connected to the connecting end, and the thickness of the bellows 1 is 0.15-0.20mm , the length is 136mm. The connecting end of the present embodiment is a straight pipe 3, and one end of the straight pipe 3 is provided with a welding step 2. It is welded with the straight pipe 3 to connect the card platform, and the outer surface of the welding step 2 is processed with a small annular groove 21 near the first port of the welding step 2. The cross section of the annular groove 21 is semicircular, and its radius is 0.5mm. The distance between the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com