Device and method for testing mechanical properties of ceramic material under constraint condition

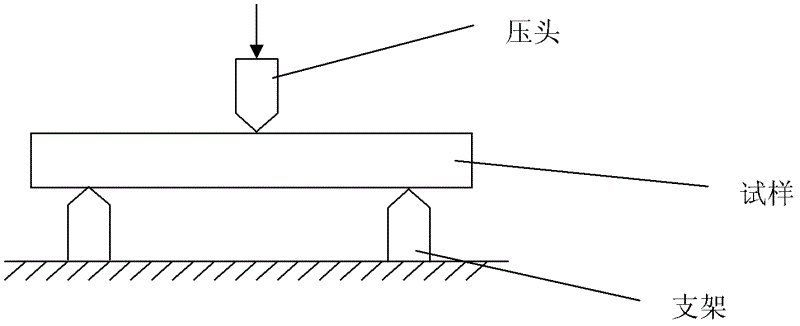

A technology of ceramic materials and constraints, which is applied in the direction of applying stable tension/pressure to test the strength of materials, which can solve the problems of complex structure and large equipment, and achieve the effect of improving the brittleness of ceramics, simple structure, and realizing mechanical property testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

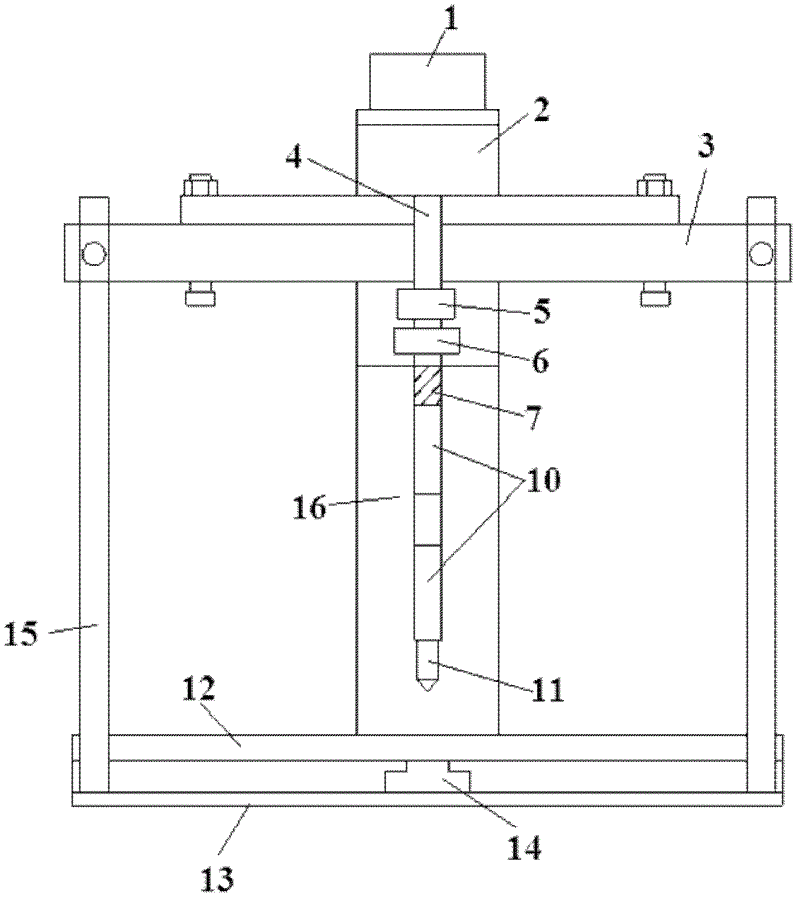

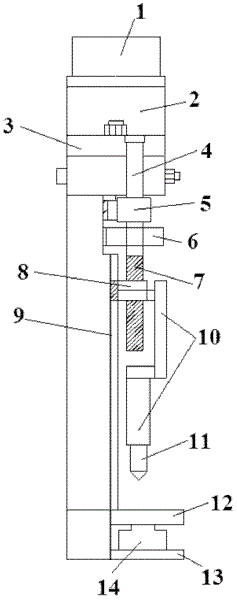

[0049] A device for testing the mechanical properties of ceramic materials under restraint conditions, said device comprising: a force applying device, a restraint device and a data acquisition and processing system;

[0050]Among them, the force applying device includes an AC motor 1, a reducer 2, a first support frame 15, a second support frame 16, a support plate 3, a bearing 5, a shaft coupling 6, a ball screw 7, a moving nut 8, and a transmission platform 10 , the pressure head 11, the working platform 12, the first base 13 and the first pressure sensor 14;

[0051] Wherein, the first base 13 is a rectangular platform, and the support plate 3 is fixedly connected with the first base 13 through the first support frame 15 and the second support frame 16, wherein the first support frame 15 symmetrically supports the two ends of the support plate 3, and the second The support frame 16 supports the middle part of the support plate 3; the two ends of the work platform 12 have t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com