Flexible body dynamics analysis method of large-scale hard rail machining centre

A dynamic analysis, machining center technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to meet the needs of accurate analysis, and achieve the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0027] The present invention adopts three-dimensional software to model firstly, and then adopts analysis software to simulate and analyze, and utilizes the characteristics of seamless connection of the two kinds of software to jointly perform flexible body dynamics analysis on a large hard rail machining center. Concrete steps of the present invention are as follows:

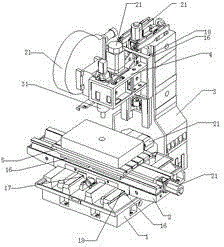

[0028] 1. Modeling of hard rail machining center: In this example, PRO / ENGINEER software is used for modeling, and the following is the same. In the standard mode of PRO / ENGINEER software, use parameters (Parameters) and relations (Relations) to carry out separate parametric geome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com