Light-emitting diode (LED) circuit board component

A technology of LED circuit boards and flexible circuit boards, which is applied in the direction of printed circuits connected with non-printed electrical components, can solve the problems of large heat generation, high copper foil cost, high material cost, etc. The effect of prolonging the working length and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

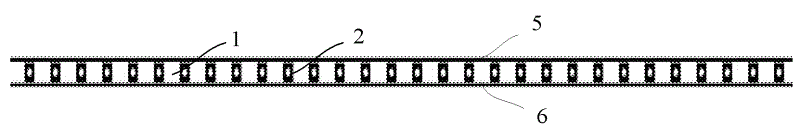

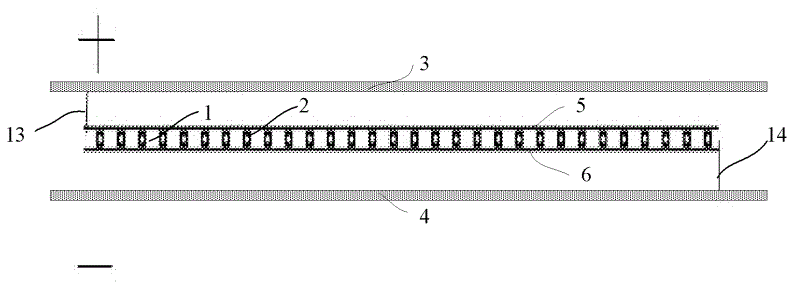

[0028] Hereinafter, a flexible printed circuit board suitable for mounting LEDs and other components will be used as a specific embodiment to describe the present invention in more detail. It should be understood that the present invention is not only applicable to single-sided flexible printed circuit boards, but also applicable to double-sided flexible printed circuit boards or multilayer LED circuit boards, and is also applicable to rigid circuit boards (also referred to as "hard boards" in the industry).

[0029] The term "single-sided flexible printed wiring board" means that a circuit is provided on only one side of the flexible printed wiring board. The term "double-sided flexible printed wiring board" means that the flexible printed wiring board is provided with lines on both sides.

[0030] Before describing the present invention in detail, those skilled in the art should understand that “element” should be understood in the broadest sense in this application, that is, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com