Energy-saving, highly-efficient and microvibration-type fine linear sieving machine

A linear sieve and micro-vibration technology, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of low sieving efficiency, large sieving power consumption, and short service life of the sieving machine, and achieves extended life, Cost saving and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

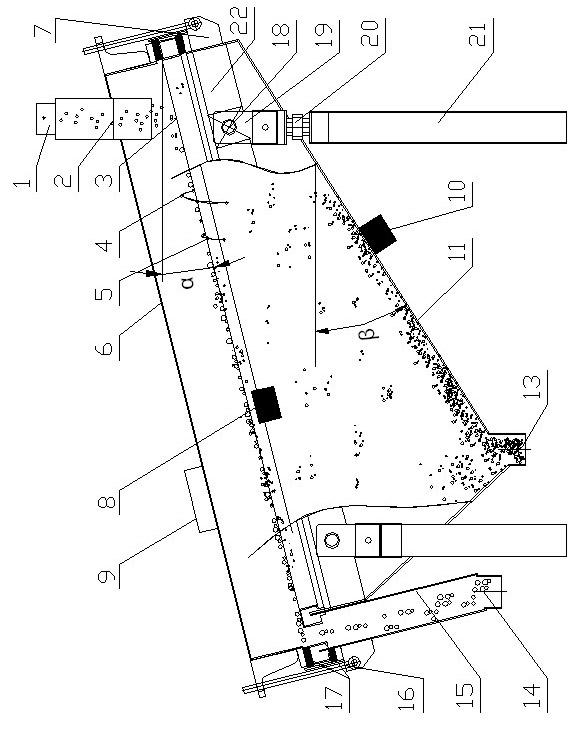

[0066] like image 3 The shown energy-saving, high-efficiency, micro-vibration fine linear screening machine (the following embodiments are referred to as linear screen), includes a frame 22, a screen 3, a grid 7 for fixing the screen 3, and a feed port 1. Coarse powder outlet 14, vibrating sieve cover 6 and its observation window 9 and vibrating sieve bottom 11, grid frame 7 is installed between vibrating sieve cover 6 and vibrating sieve bottom 11, respectively sealed by gasket 17, vibrating sieve bottom is fixed on the machine The frame below is also provided with a fine powder outlet 13, the feed inlet 1 is arranged above the vibrating screen cover 6, and the coarse powder outlet 14 is arranged on one side of the frame. The grid frame 7 is provided with damping spokes 7-3 which can reduce the amplitude of the mesh surface of the screen. The vibrating screen cover 6 and the vibrating screen bottom 11 are compressed by a cover pressing mechanism 16. The cover pressing mecha...

Embodiment 2

[0076] A linear sieve whose mesh surface size is 800x1200mm, concrete structure is the same as embodiment 1, adopts Figure 4 The vibration-reducing amplitude net in the medium uses a 200-mesh screen, and a 120-watt two-pole vibrating motor is fixed at the bottom of the vibrating screen, that is, the total power of the screening machine is 120 watts.

[0077]

Embodiment 3

[0079] A linear sieve whose mesh surface size is 800x1200mm, concrete structure is the same as embodiment 1, adopts Figure 4 The vibration-reducing amplitude net in the medium uses a 200-mesh screen, and a 30-watt electromagnetic bin wall vibrator is used at the bottom of the vibrating screen.

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com