Water-cooled welding gun for molten gas bath coupling active TIG welding

A gas and molten pool technology, applied in the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problems of increased equipment investment, low production efficiency, shortened life of tungsten electrodes, etc., to achieve increased contact area, good cooling effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

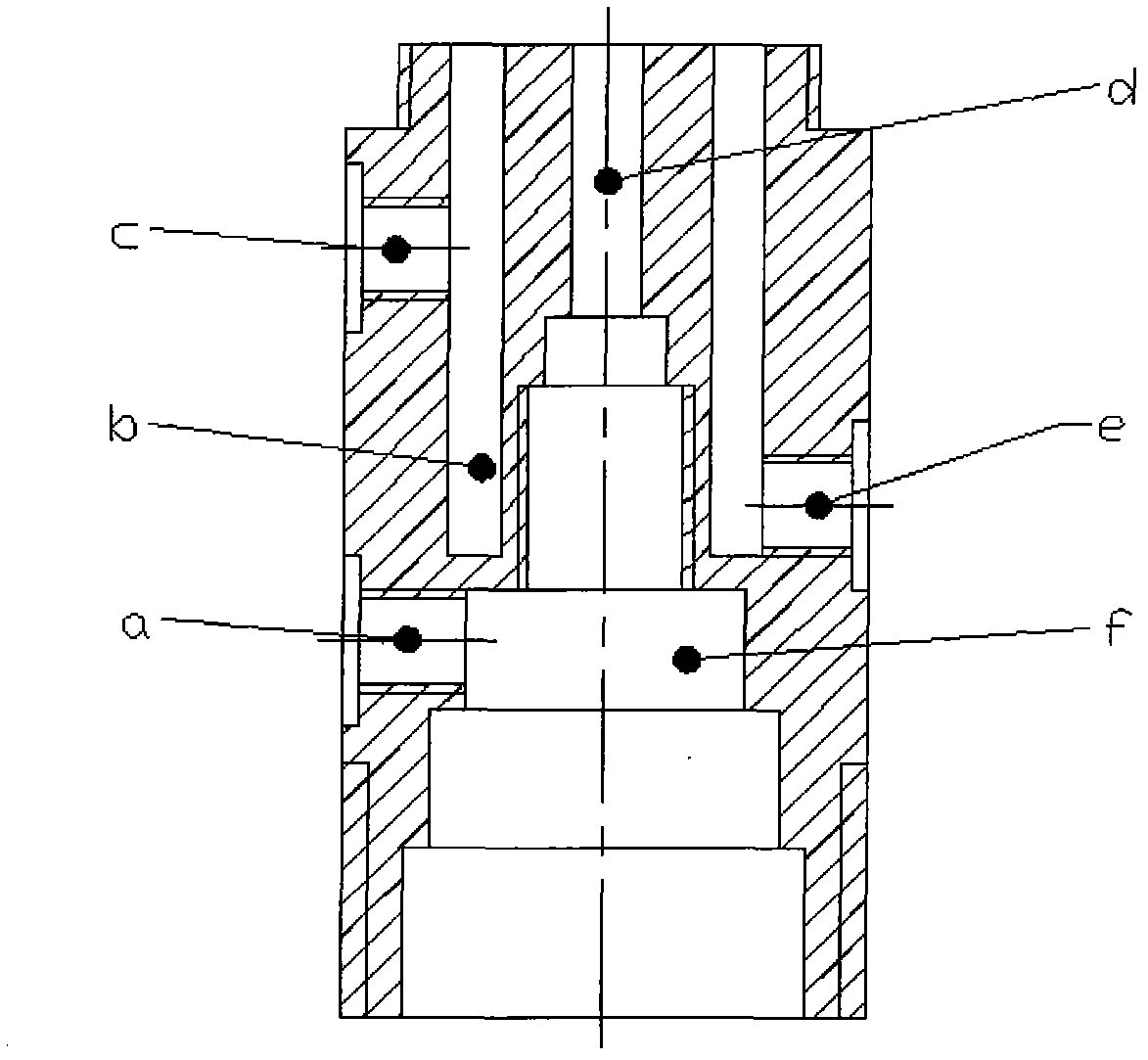

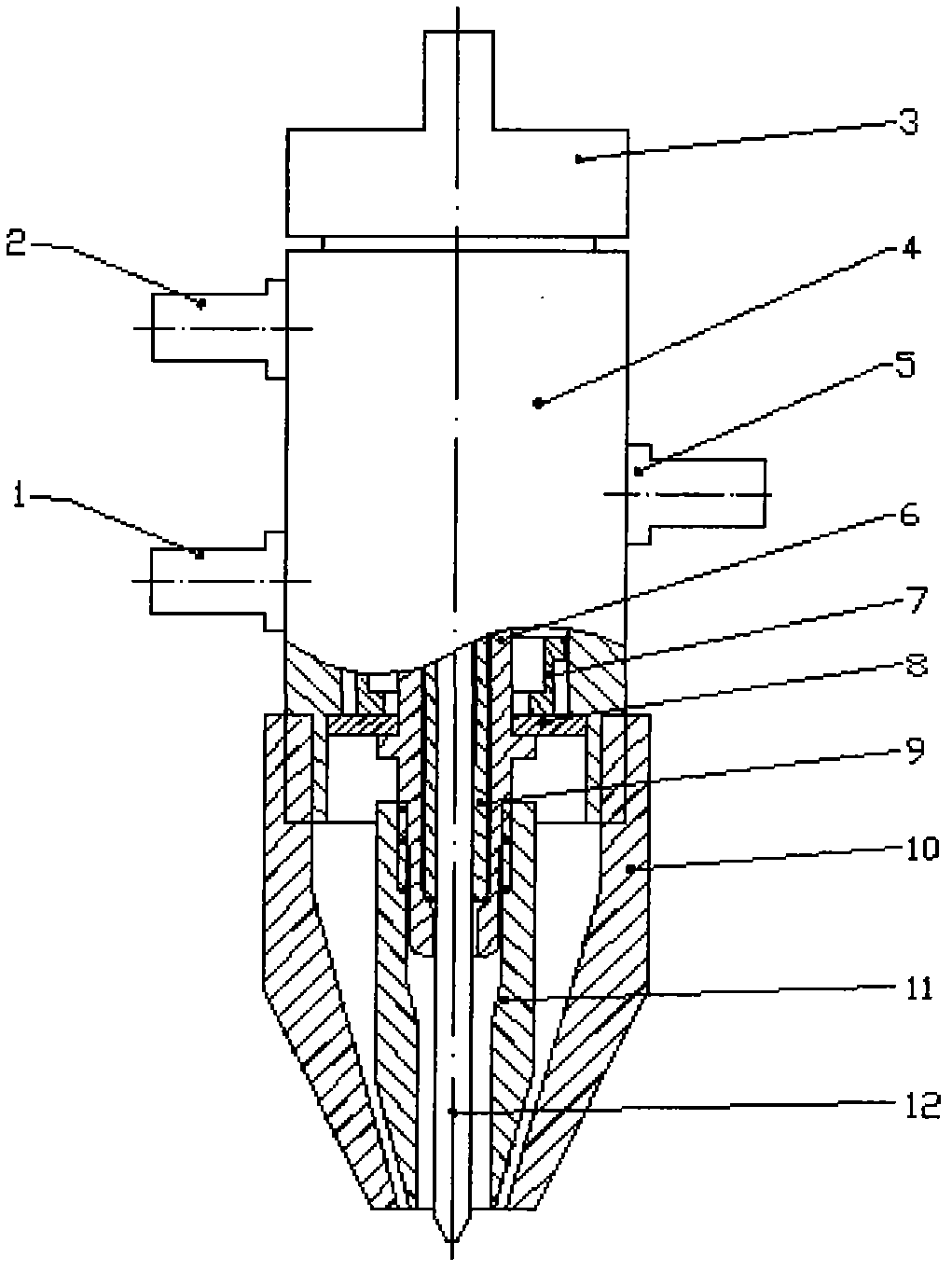

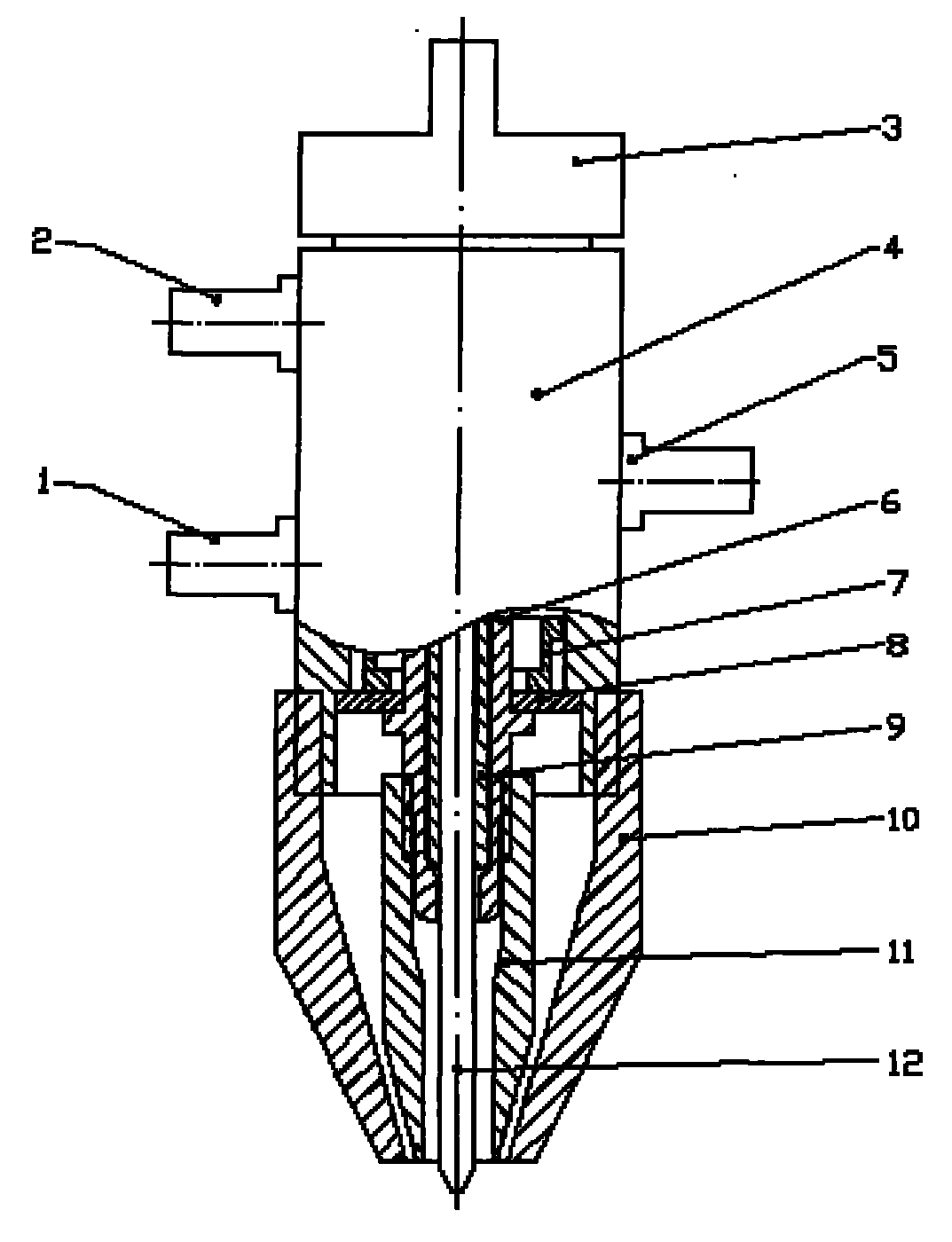

[0012] Such as figure 1 , figure 2 As shown, the present invention is a water-cooled welding torch for gas molten pool coupling active TIG welding. There is a torch body 4, an inner layer gas vent hole is arranged in the center of the upper part of the torch body 4, a cooling water tank b is arranged in the torch body, and an introduction The air chamber f of the outer layer gas, the side of the gun body is provided with an outer layer gas inlet hole a, a cooling water inlet hole e, and a cooling water outlet hole c, and there is a gun body sealing nut 3 for sealing the gun body cooling water tank b, which is electrically conductive A tungsten chuck 9 is placed inside the nozzle 6, the inner nozzle 11 is connected to the lower end of the conductive tip 6, the conductive tip 6 is connected to the lower part of the gun body 4, the outer nozzle 10 is connected to the outside of the gun body 4, two air screens 7, 8 Covered on the outside of the contact tip 6, it is fixed up and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap