Welding gun for coupling active TIG welding of gas weld pool

A gas and molten pool technology, applied in the direction of electrode characteristics, welding equipment, arc welding equipment, etc., can solve the problems of low production efficiency, high welding cost, increased cost, etc., and achieve the effect of convenient operation, simple and compact structure, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

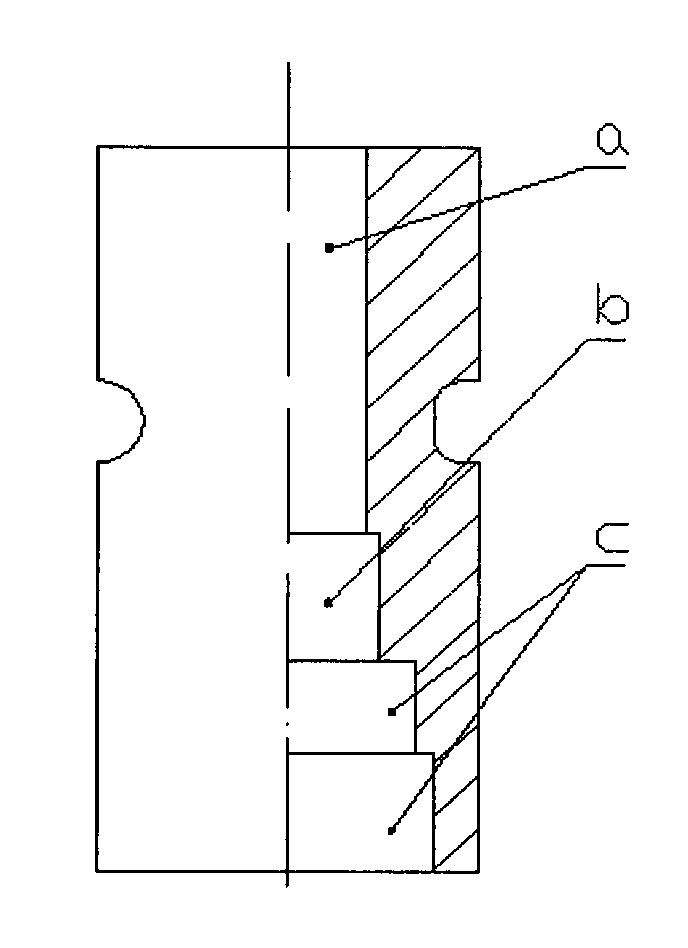

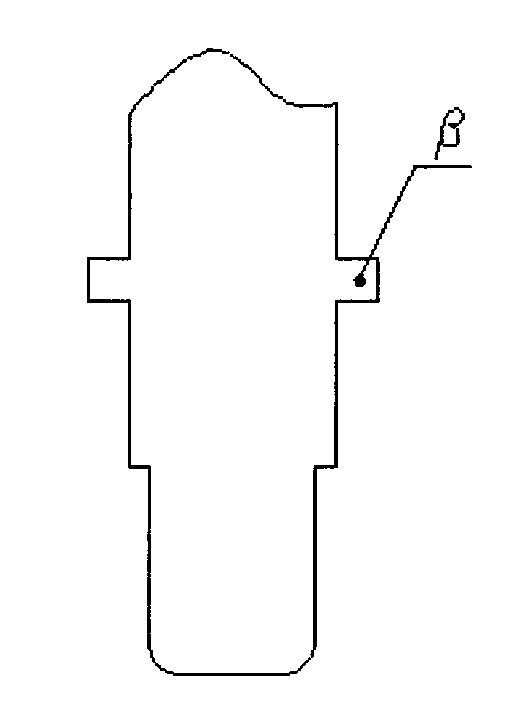

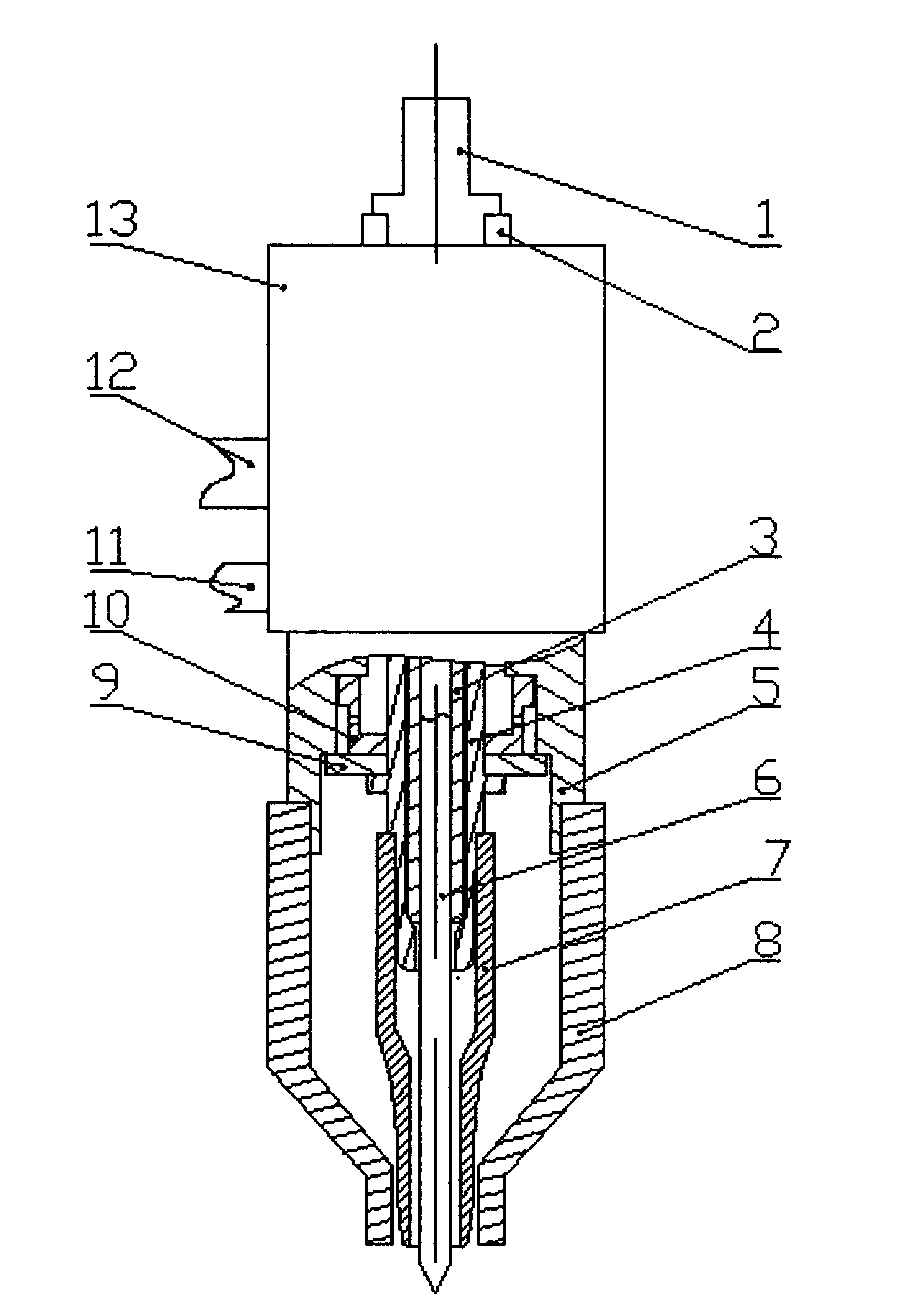

[0015] Such as figure 1 , figure 2 , image 3 As shown, the welding torch for gas molten pool coupling active TIG welding of the present invention has a torch body 5, a conductive tip accommodating chamber a is arranged in the center of its upper part, and a gas chamber b for introducing outer layer gas is arranged in the lower part; the conductive tip 4 is installed in the accommodating chamber a of the conductive tip, and a tungsten pole chuck 3 is installed inside, and a boss β is arranged on the outside, the outer wall of the screw sleeve 1 is connected with the inner wall of the conductive tip 4, and the tungsten electrode 6 is tightened, The upper part of the screw sleeve 1 is connected to the inner gas inlet pipe; the gasket 2 is set on the lower part of the screw sleeve 1 to prevent the contact tip from moving up and down in the gun body; the tungsten electrode chuck 3 is installed inside the contact tip 4; the tungsten electrode 6 is fixed on the tungsten electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com