Integral cutting fluid conveyer device

A conveying device and cutting fluid technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of affecting tool cooling and lubrication, uneven mixing of cutting fluid, and affecting workpiece processing, etc., to achieve Cutting fluid and water are evenly mixed, saving manufacturing cost and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

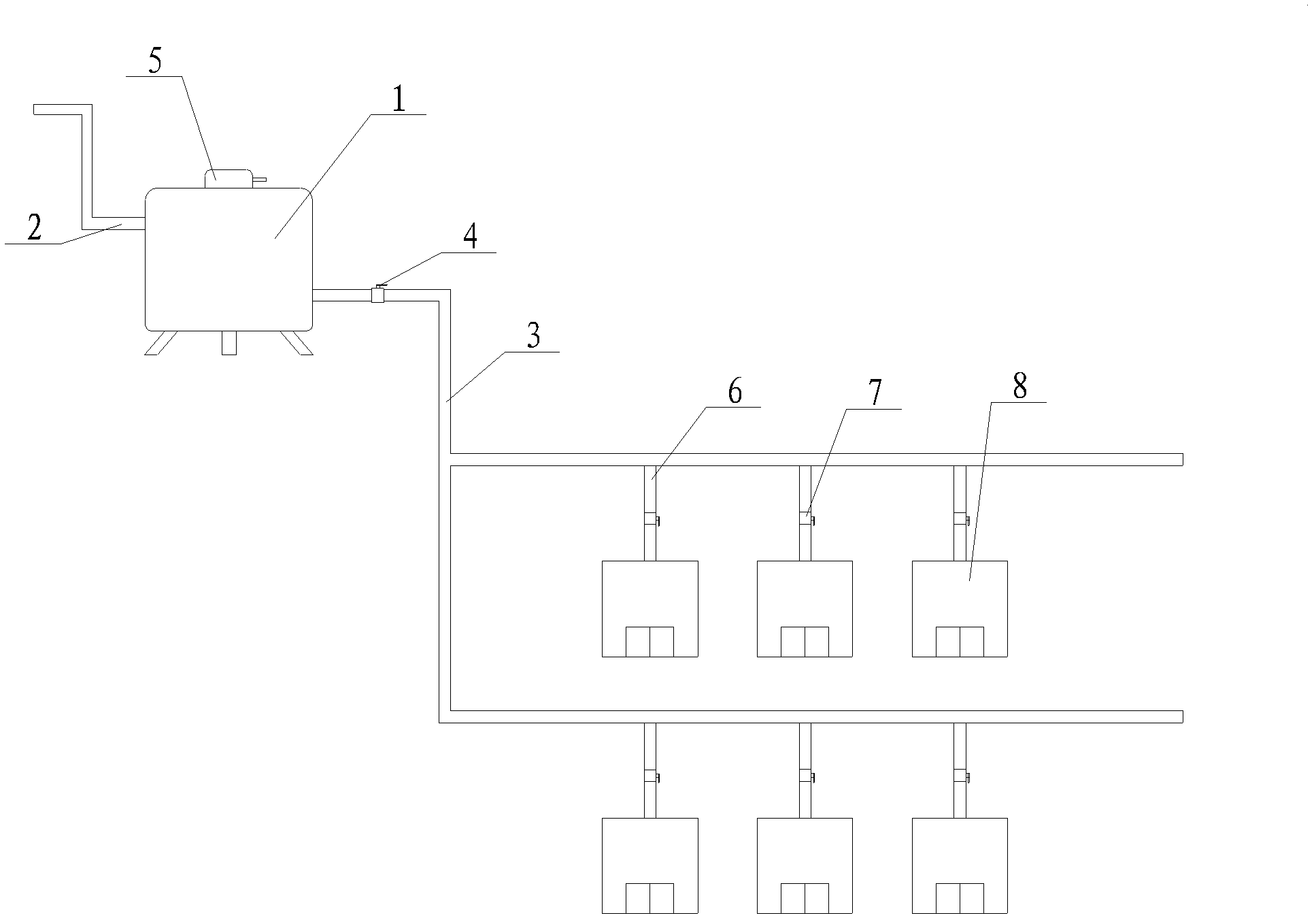

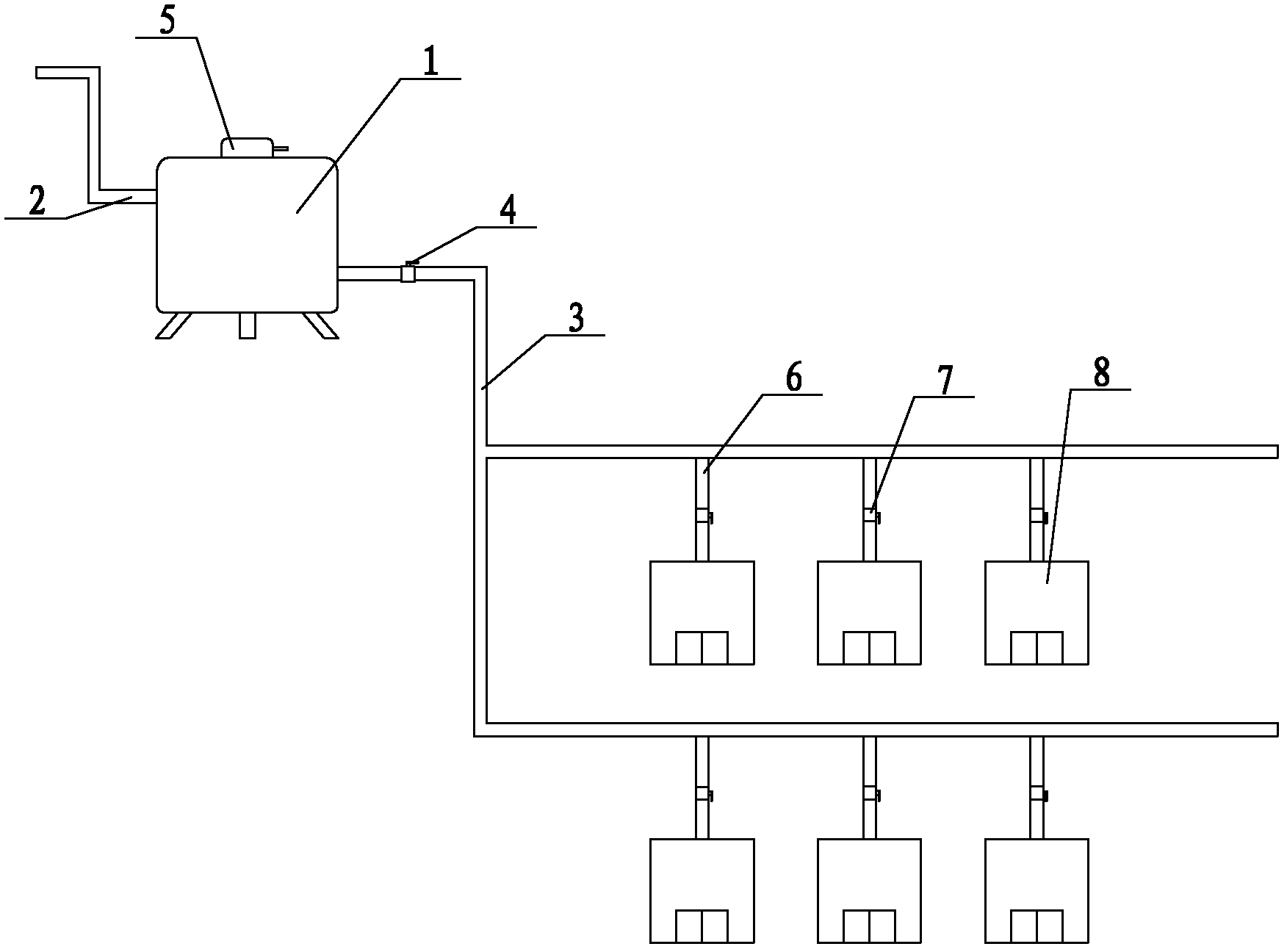

[0015] Such as figure 1 As shown, the integrated cutting fluid delivery device of the present invention includes an automatic oil mixer 1, and the two sides of the automatic oil mixer 1 are respectively provided with a water inlet pipe 2 and a mixed fluid pipeline 3, and the mixed fluid pipeline 3 is provided for controlling the mixing The main valve 4 where the final liquid flows out is provided with a number of branch pipes 6 on the mixed liquid pipe 3, and the ends of the branch pipes 6 are connected with the machining center 8, and the cutting fluid and water are first mixed with the automatic oil mixer 1 and then sent to each The use of the machining center 8 not only makes the entire mixing process simple, but also makes the cutting fluid and water mix more uniformly, ensuring that the work of the machining center 8 is carried out smoothly.

[0016] In specific implementation, in order to make the cutting fluid and water mix better, the height of the nozzle of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com