Single-phase solid solution cast or wrought magnesium alloys

A technology for casting magnesium alloys and magnesium alloys, which is applied in the field of single-phase solid-solution magnesium alloys, and can solve problems such as insufficient mechanical properties and corrosion resistance, and recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

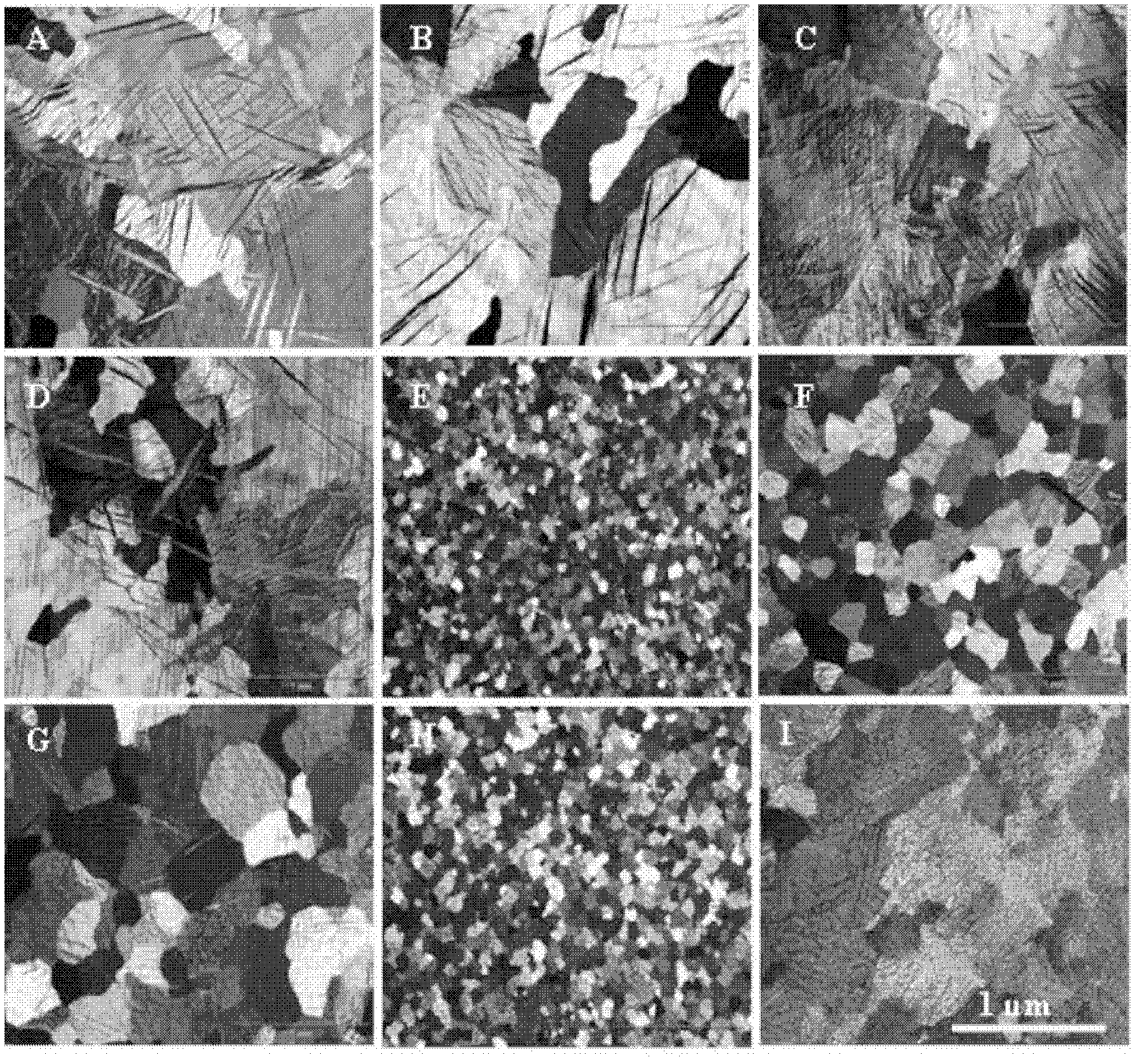

Image

Examples

Embodiment Construction

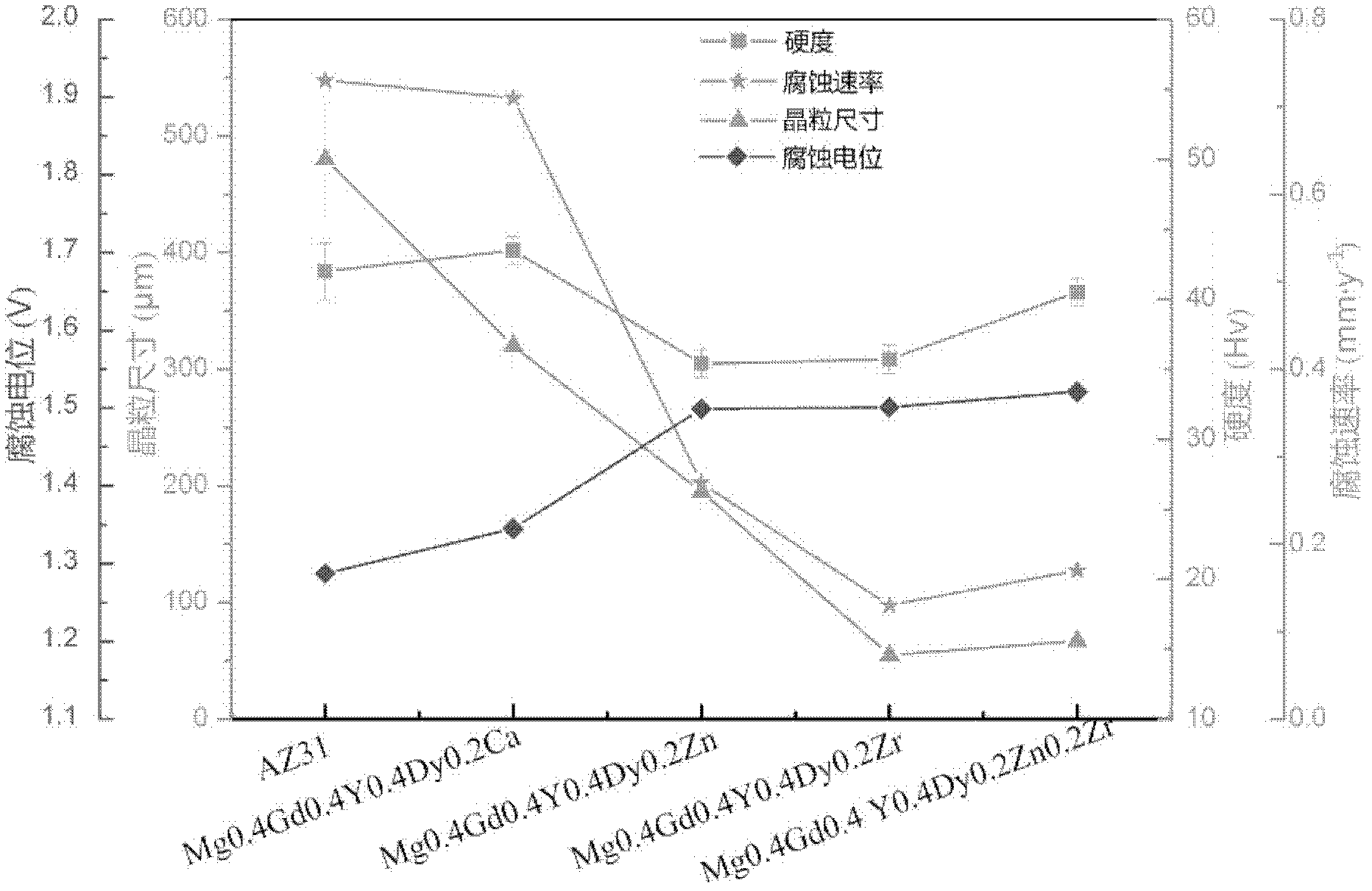

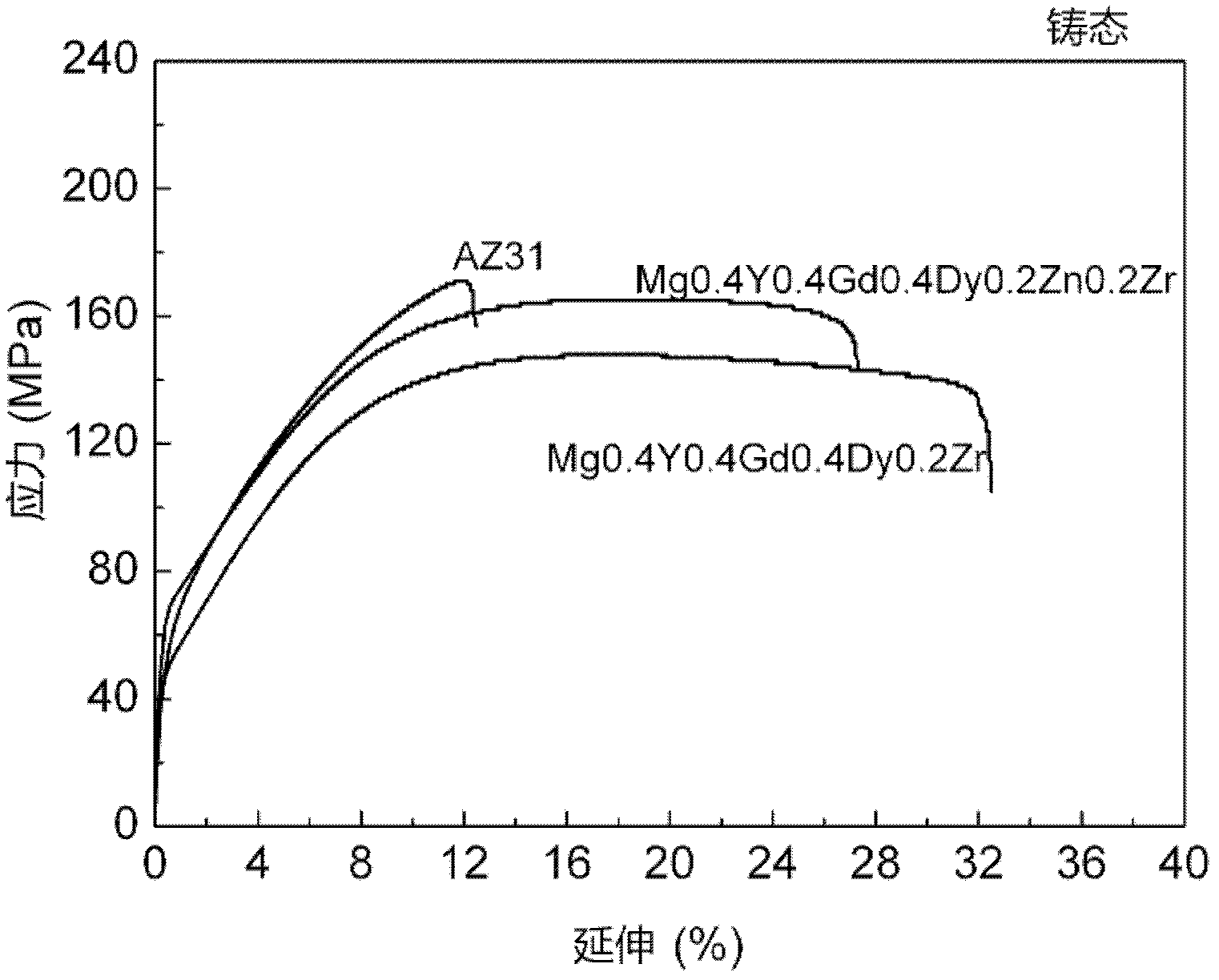

[0011] The strengthening effect of rare earth elements on existing magnesium alloys is explained by two mechanisms, namely precipitation strengthening and solid solution strengthening. Precipitation strengthening, especially age hardening, has been emphasized to contribute to the improvement of mechanical properties. However, without being bound by any theory, studies have shown that in the alloys involved in the present invention, precipitation strengthening does not exist, and solid solution strengthening is the main mechanism for the improvement of the mechanical properties of the magnesium alloys in the present invention.

[0012] It was further shown that solid solution strengthening depends on the content of alloying elements in the magnesium matrix and the difference in atomic radii between these elements and magnesium, that is, higher alloying element content as well as alloying elements with larger atomic radii difference are both Contributes to solid solution strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com